Sectional type pressurizing solid solution nitriding accelerating method of austenitic stainless steel

An austenitic stainless steel, segmented technology, used in solid-state diffusion coating, coating, metal material coating technology and other directions, can solve the problem of reducing the solid solution nitriding temperature, reduce costs and equipment loss, shorten the Process cycle, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

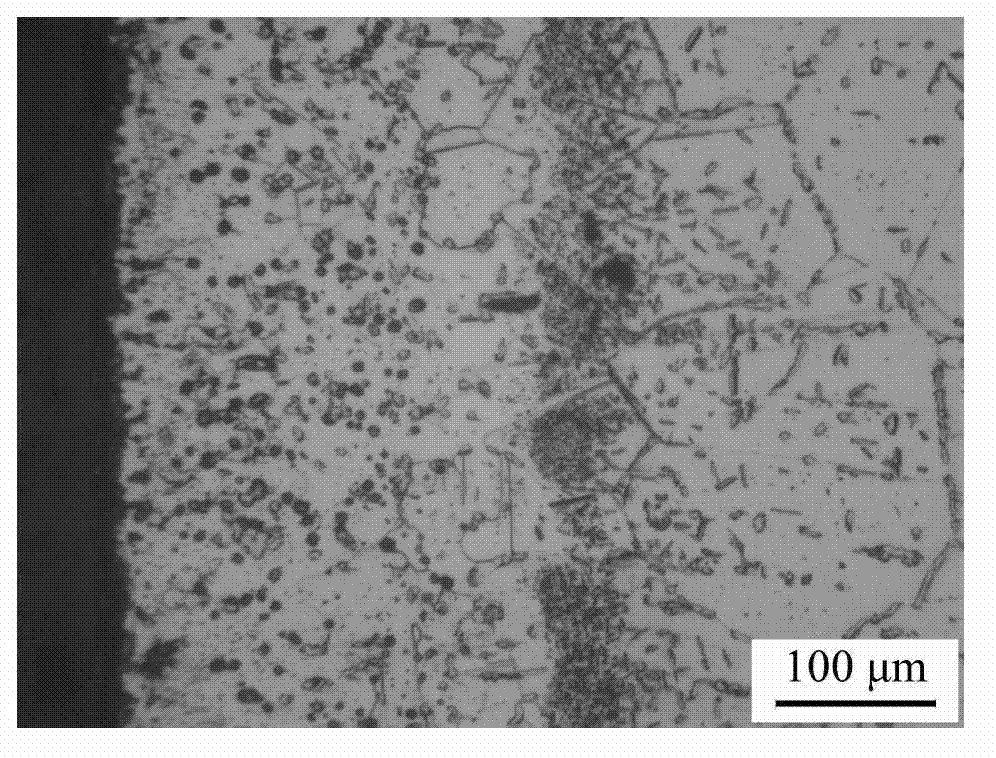

[0017] Process 304 austenitic stainless steel into a thin plate and hang it in a solid solution nitriding furnace with the patent name "A pressurized high-temperature nitriding device with a double-pressure balance structure" and application number 201210530358.6, and pass it at 0.5L / min into NH 3 gas, heated to 500°C, and nitrided for 10 hours under the pressure of 0.25MPa. Then the NH in the furnace 3 Discharge and feed N at a flow rate of 5L / min 2 , rapidly heated to 1150 ° C, solid solution nitriding under 0.25MPa pressure conditions for 10h, and then rapidly water-cooled to room temperature. The thickness of the solid solution nitrided layer obtained in this embodiment can reach about 311 μm, such as figure 1 shown.

Embodiment 2

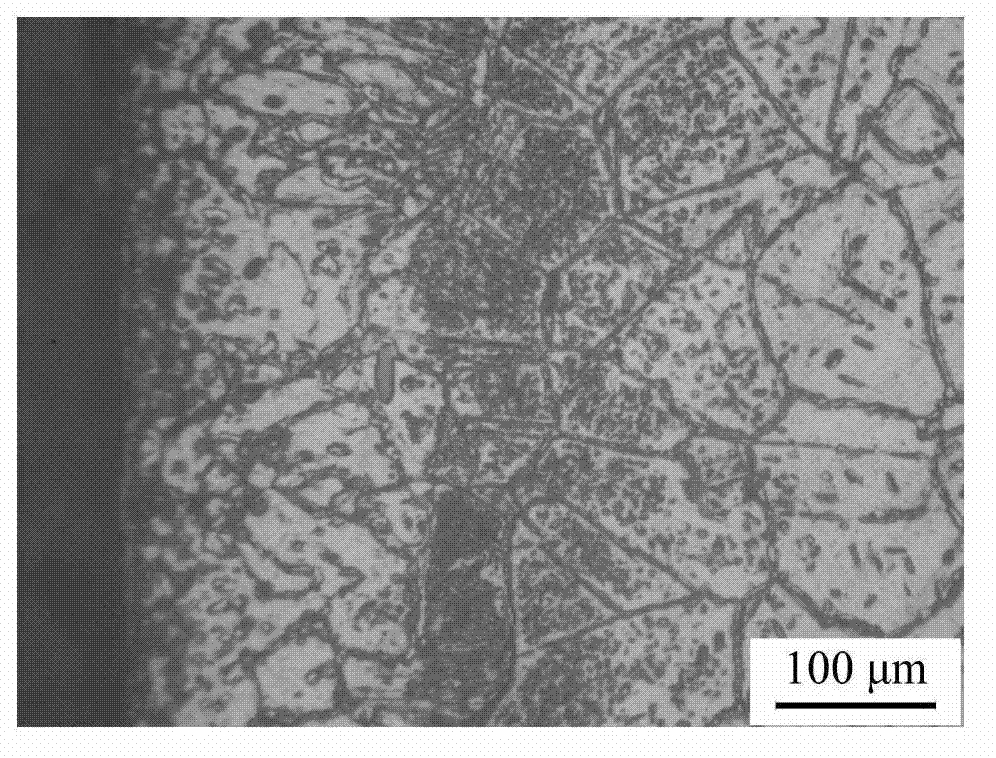

[0019] Process 304 austenitic stainless steel into a thin plate and hang it in the solid solution nitriding furnace with the patent name "A pressurized high-temperature nitriding device with a double-pressure balance structure" patent number 201210530358.6, and feed NH at 1L / min 3 gas, heated to 700°C, and nitrided for 5h under the pressure of 0.1MPa. Then the NH in the furnace 3 Discharge and feed N at a flow rate of 3L / min 2 , rapidly heated to 1050 ° C, solid solution nitriding under 0.15MPa pressure conditions for 10h, and then rapidly cooled to room temperature with water. The thickness of the solid solution nitrided layer obtained in this embodiment can reach about 160 μm, such as figure 2 shown.

Embodiment 3

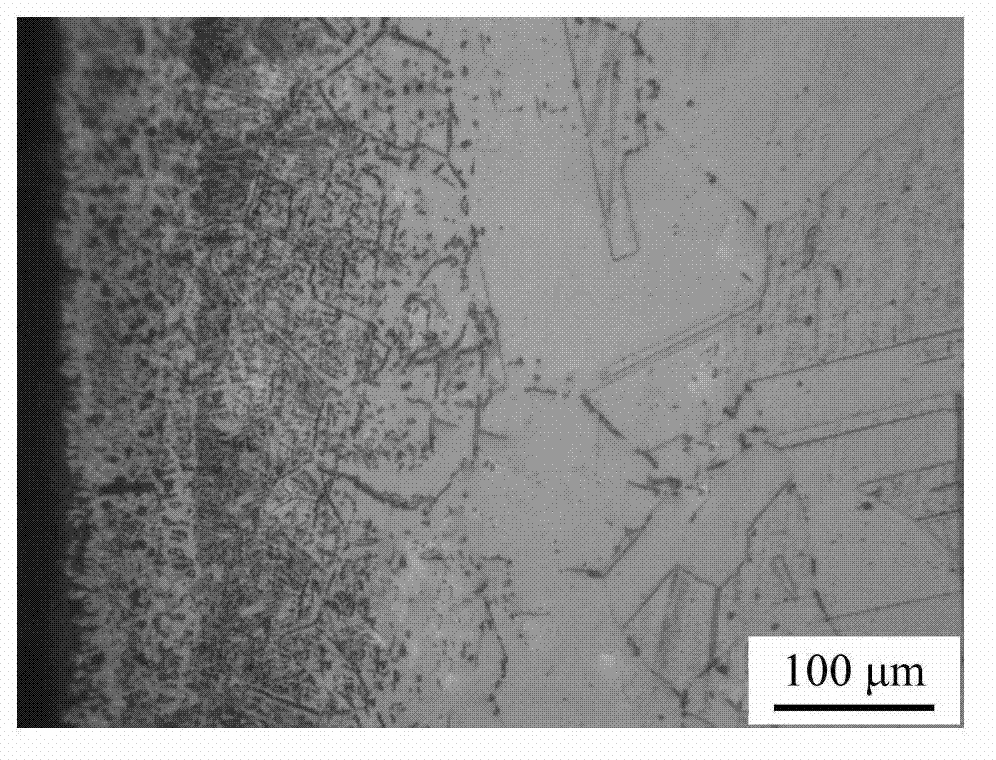

[0021] Process 316 austenitic stainless steel into a thin plate and hang it in the solid solution nitriding furnace with the patent name "A pressurized high-temperature nitriding device with a double-pressure balance structure" patent number 201210530358.6, and feed NH at 1L / min 3 gas, the temperature was raised to 600°C, and nitriding was carried out for 5 hours under the pressure of 1.0MPa. Then the NH in the furnace 3 Discharge and feed N at a flow rate of 5L / min 2 , quickly raised the temperature to 900°C, solid solution nitriding under 1.0MPa pressurized condition for 1h, and then rapidly water-cooled to room temperature. The thickness of the solid solution nitrided layer obtained in this embodiment can reach about 90 μm, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com