Vacuum glow ion nitriding process for reducing deformation of precision gears of industrial robots

A technology of glow ion permeation and industrial robots, which is applied in the field of nitriding technology, can solve the problems of high heat treatment technology requirements and difficulty in meeting the nitriding treatment requirements of such parts, and achieve shortened nitriding time, good comprehensive mechanical properties, heating uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

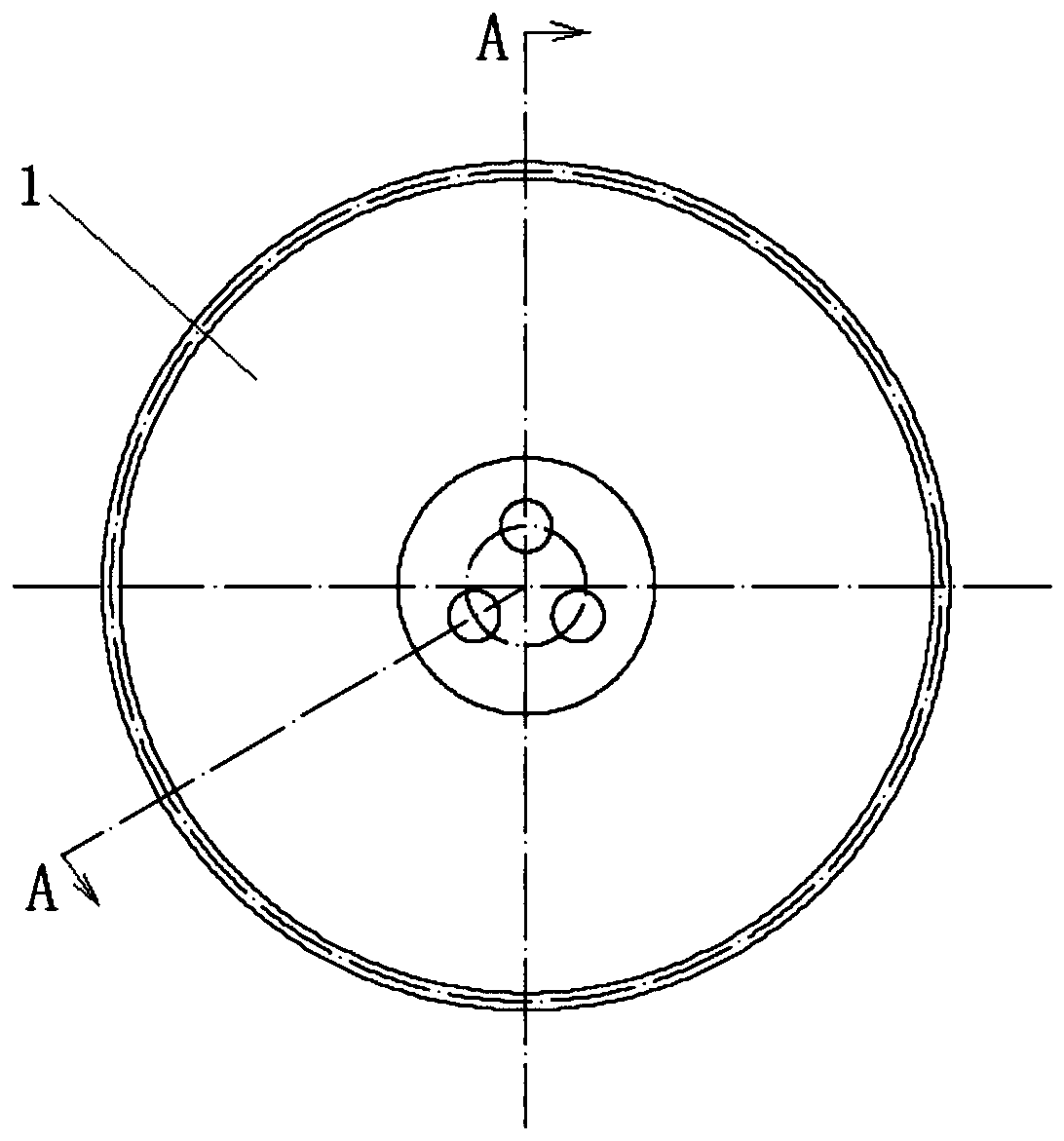

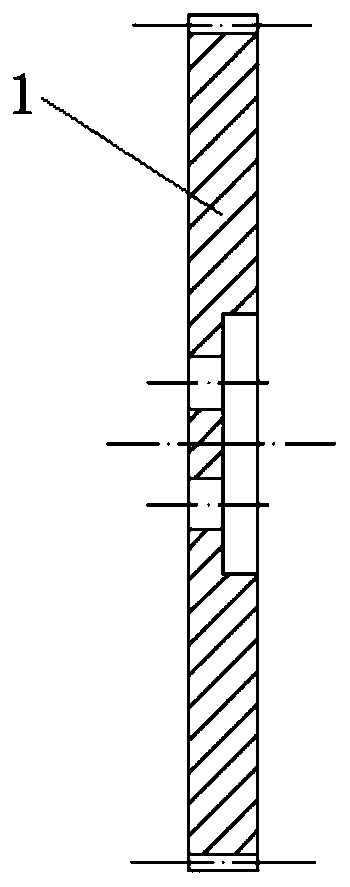

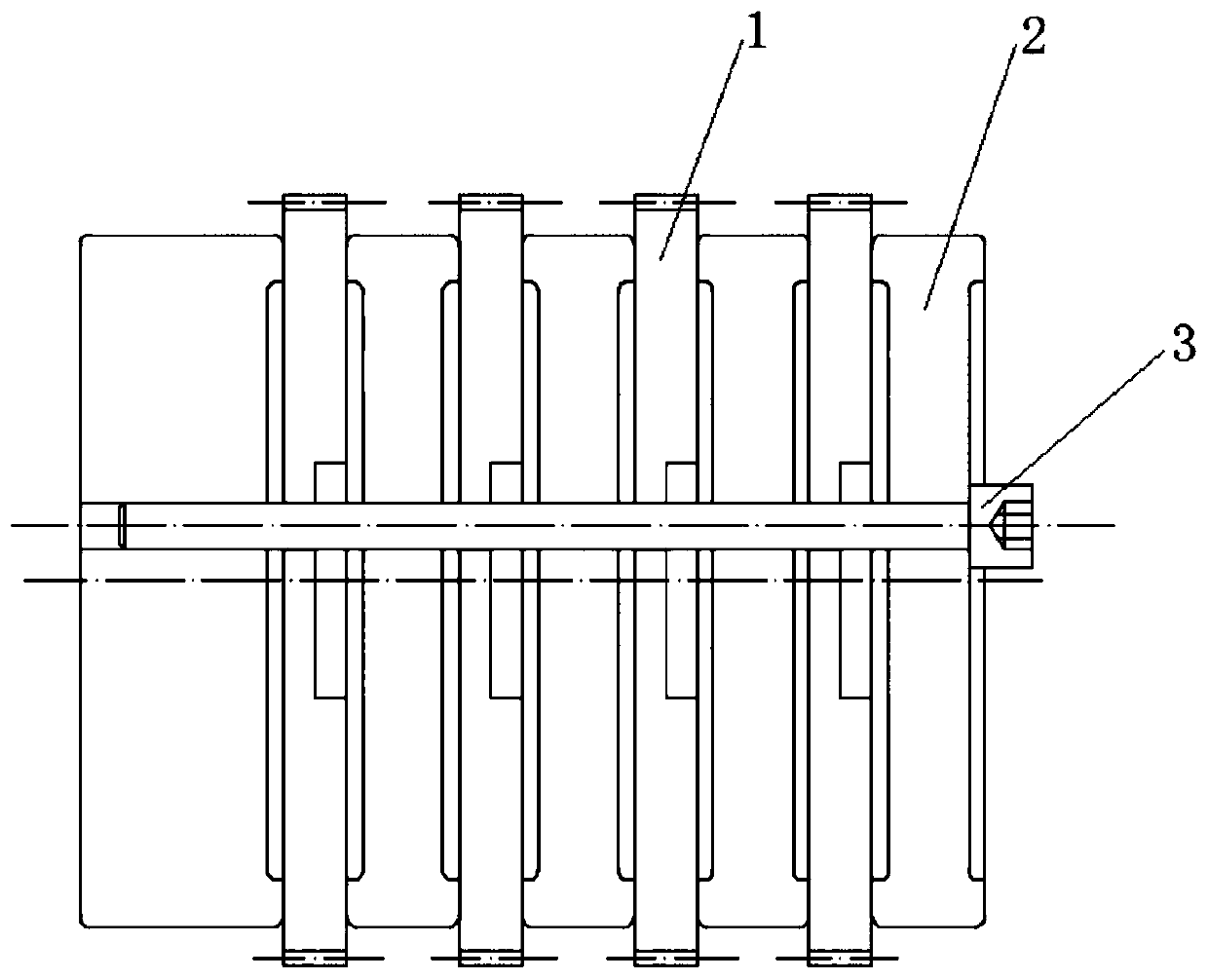

[0046] Taking the nitriding treatment process of an industrial robot precision gear with a modulus of 0.5 and a number of teeth of 97 as an example, the heat treatment technical requirements are: surface hardness ≥ 700HV, effective hardened layer depth of 0.15-0.26mm (limit value 400HV, PCD ( pitch circle diameter) position), the gear accuracy is JIS1~3 (the gear accuracy before heat treatment is 1~1.5), and the plane parallelism tolerance is ±0.012mm (the plane parallelism tolerance before heat treatment is ±0.007mm). In order to meet the above heat treatment requirements, such as Figure 5As shown, a vacuum glow ion nitriding process for reducing the deformation of precision gears of industrial robots in this embodiment includes the following steps:

[0047] (1) Parts preparation: Quenching and tempering the gear blank so that the hardness of the blank reaches 31-32.5HRC. After quenching and tempering, good comprehensive mechanical properties can be obtained, which can effec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com