Preparation method of nitrogen-doped porous carbon material

A technology of nitrogen-doped porous carbon and nitrogen-doped carbon, which is applied in the direction of carbon preparation/purification, electrical components, electrochemical generators, etc., can solve problems such as limitations, hindering development and application, and high prices, and achieve low production costs, High yield, easy and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Preparation of nitrogen-doped carbon material

[0026] Step 1. At room temperature, dissolve 4 g of glucose, 5 g of melamine, and 3 g of zinc chloride in deionized water and stir for 3 hours to form a complex precipitate, then dry to obtain a carbonized precursor, and put it in a 100°C drying oven dry overnight;

[0027] Step 2. Put the material obtained in step 1 into a tube furnace after being ground, pass in an inert gas, and raise the temperature to 700°C at a heating rate of 5°C / min and keep it warm for 2 hours for carbonization. After cooling, take it out ;

[0028] In step 3, the nitrogen-doped carbon material containing metal ions is first washed with hydrochloric acid, then ethanol and deionized water, filtered, and vacuum-dried to obtain the nitrogen-doped porous carbon material CNC-3.

Embodiment 2

[0029] Embodiment 2: Preparation of nitrogen-doped carbon material

[0030] Step 1. At room temperature, dissolve 4g glucose, 5g melamine, and 1g zinc chloride in deionized water and stir for 3 hours to form a complex precipitate, then dry to obtain the carbonized precursor, and put it in a drying oven at 100°C for drying dry overnight;

[0031] Step 2. Put the material obtained in step 1 into a tube furnace after being ground, pass in an inert gas, and raise the temperature to 700°C at a heating rate of 5°C / min and keep it warm for 2 hours for carbonization. After cooling, take it out ;

[0032] In step 3, the nitrogen-doped carbon material containing metal ions is first washed with hydrochloric acid, then washed with ethanol and deionized water, filtered, and vacuum-dried to obtain the nitrogen-doped porous carbon material CNC-1.

Embodiment 3

[0033] Embodiment 3: Preparation of nitrogen-doped carbon material

[0034] Step 1. At room temperature, dissolve 4g of glucose and 5g of melamine in deionized water and stir for 3 hours to form a complex precipitate, then dry to obtain a carbonized precursor, and put it in a 100°C drying oven to dry overnight;

[0035] Step 2. Put the material obtained in step 1 into a tube furnace after being ground, pass in an inert gas, and raise the temperature to 700°C at a heating rate of 5°C / min and keep it warm for 2 hours for carbonization. After cooling, take it out ;

[0036] Step 3, the nitrogen-doped carbon material containing metal ions is first washed with hydrochloric acid, then washed with ethanol and deionized water, filtered, and vacuum-dried to obtain the nitrogen-doped porous carbon material CNC-0.

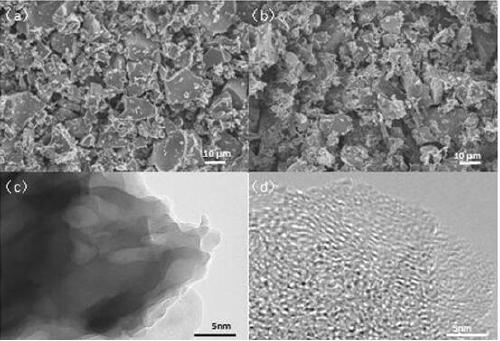

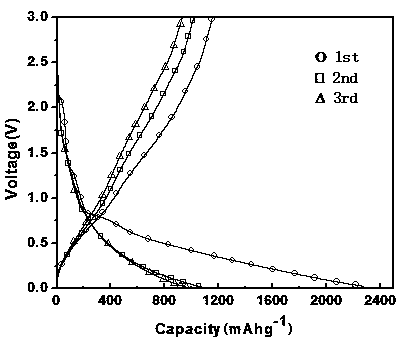

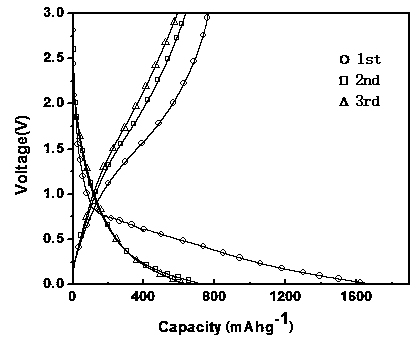

[0037] figure 1 (a) (b) SEM images of CNC-0 and CNC-3, respectively, from figure 1 As can be seen in (a), when no ZnCl was added, the CNC material was in irregular granula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com