High-emission hub unit

A hub unit, rolling element technology, applied in the direction of hubs, casters, wheels, etc., can solve problems such as insufficient to allow sludge to leave the chamber, sludge retention trapped, unsatisfactory sealing components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

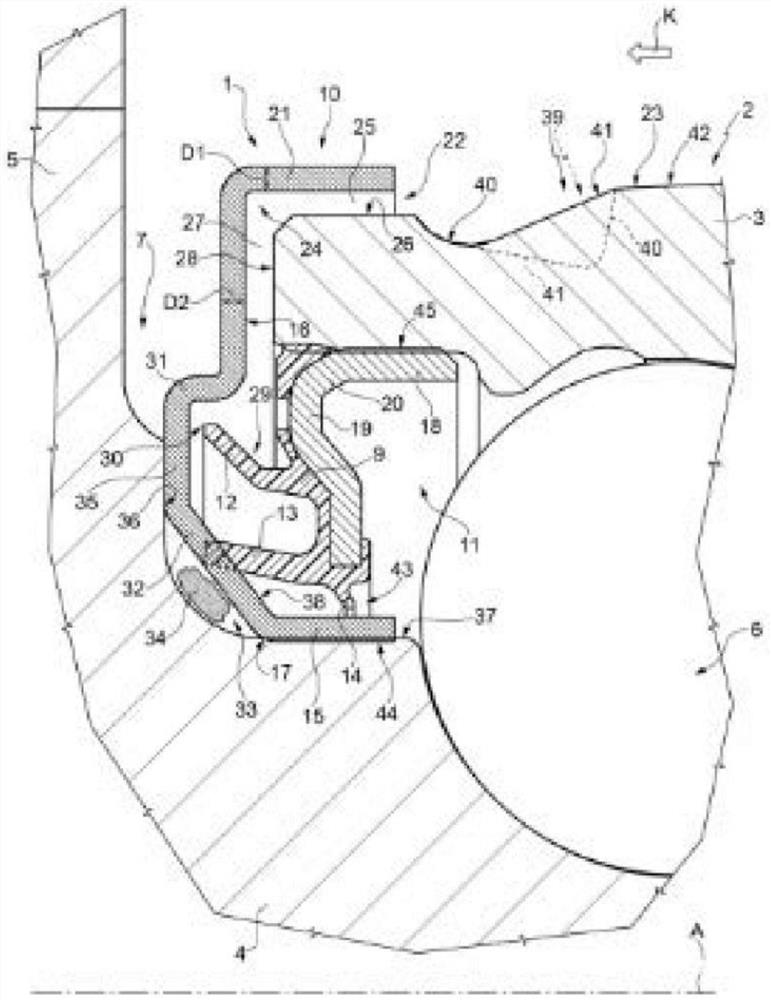

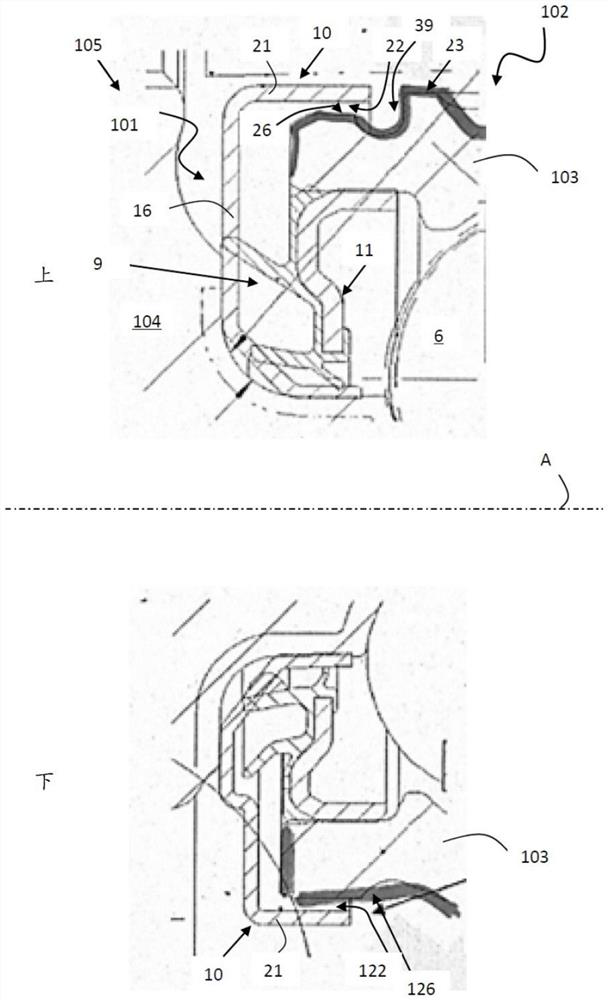

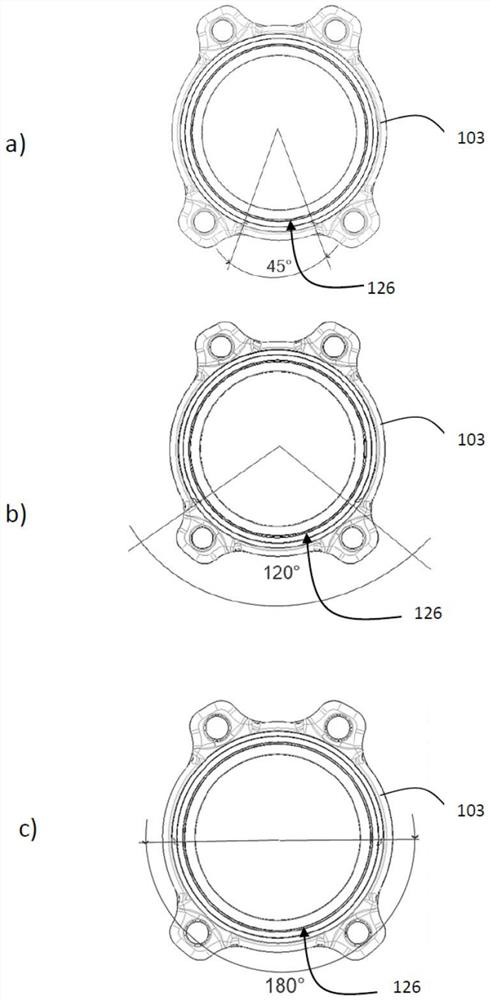

[0015] refer to figure 1 , 1 denotes a low friction sealing assembly, especially designed to be mounted on a hub unit 2 of a vehicle, the sealing assembly 1 of which forms an integral part of said unit during use. The description of this known solution as mentioned above is intended to help a better understanding of the embodiments of the present invention.

[0016] A hub unit 2 of a yet known type comprises: an outer ring 3, which is stationary ( / stationary) during use; an inner ring 4, which rotates during use around an axis A, which is also of both rings 3 and 4 an axis of symmetry; and at least one row of rolling elements 6 between an outer ring 3 and an inner ring 4 coaxial to each other; the ring 4 has a flanged end 5 opposite the outer ring 3 and for carrying the wheel.

[0017] The seal assembly 1 can be inserted into an annular gap ( / space / void) 7 defined between the rotating inner ring 4 of the hub 2 and the stationary outer ring 3 ( / stationary outer ring), and more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com