Method for evaluating performance of friction pendulum type shock insulation support for bridge and building

A technology for seismic isolation bearings and buildings, applied in bridge construction, bridges, buildings, etc., can solve the problem of inability to accurately verify the seismic isolation performance of bearings, the inability to quickly, comprehensively and accurately evaluate the seismic isolation performance, and no basis for evaluation, etc. problems, to achieve scientific and reliable evaluation methods, simple test methods, and comprehensive evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

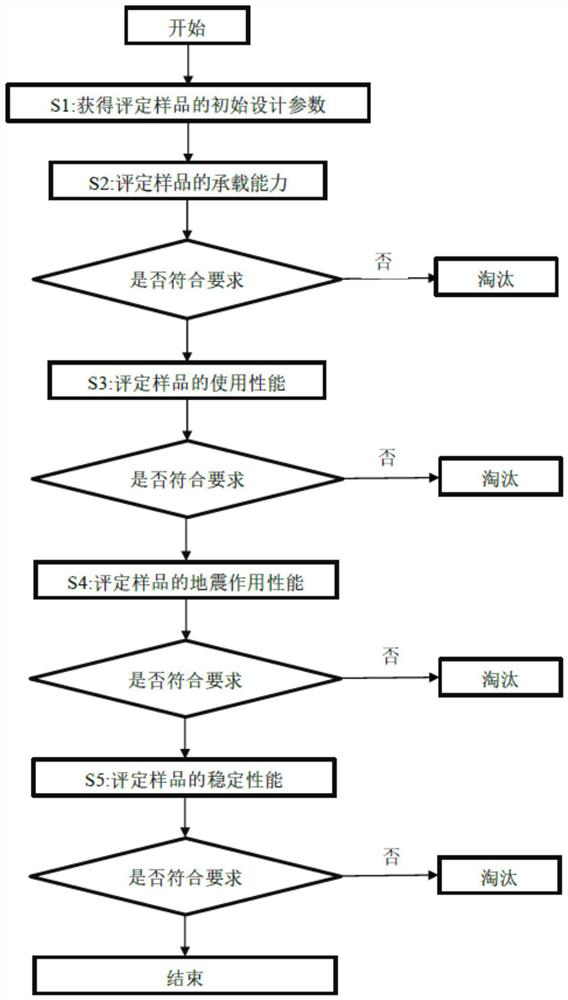

[0077] The following is an example of a building friction pendulum isolation bearing sample. According to the performance evaluation method of friction pendulum type seismic isolation bearings for bridges and buildings of the present invention, the performance evaluation of the sample is realized, and the specific steps are as follows:

[0078] (1) Obtain the initial design parameters of the assessed friction pendulum isolation bearing;

[0079] The model of the evaluated friction pendulum isolation bearing is FPS-Ⅱ-5000-350-4, the height of the bearing is 250mm, the design vertical bearing capacity is 5000kN, the design horizontal bearing capacity is 500kN, the maximum design horizontal displacement is 350mm, and the temperature influence displacement is 50mm. The maximum earthquake displacement is 300mm, the maximum static friction coefficient is 0.07, the dynamic friction coefficient is 0.055, the isolation period is 4s, and the equivalent curvature radius is 4000mm;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com