Polymer electrolyte membrane, method for producing same, and solid polymer fuel cell

An electrolyte membrane and polymer technology, which is applied in the field of solid polymer fuel cells, can solve the problems of inability to improve the chemical durability of the membrane, high cost, and complicated preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

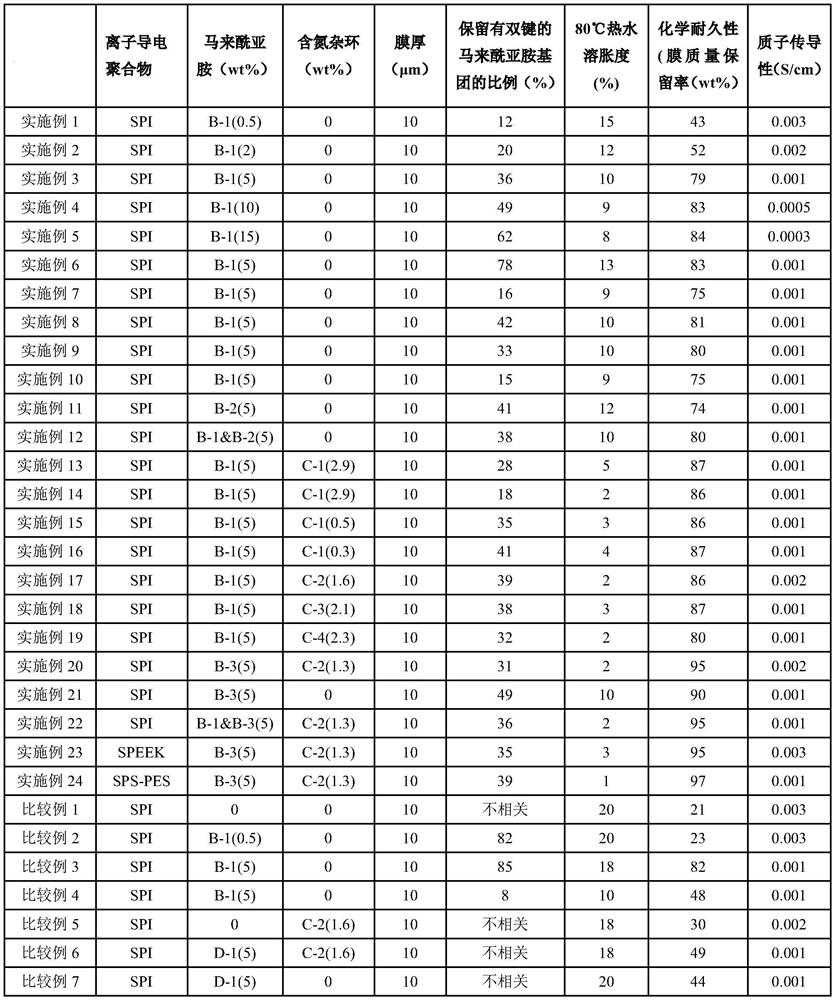

Embodiment 1

[0089] Dissolve 10.0 g of sulfonated polyimide, 0.06 g of 4,4'-bismaleimide diphenylmethane in 42 g of N-methyl-2-pyrrolidone to form a composition, and coat the composition on PET A wet film with a thickness of 120 μm is obtained on the substrate film, and then dried at 180°C for 30 minutes to completely remove N-methyl-2-pyrrolidone to obtain a dry film, and then soak the dry film in 10% dilute sulfuric acid solution for 16 hours for acidification , after washing the acidified membrane to neutrality with deionized water, dry it at 25° C. and 50% humidity to obtain a polymer electrolyte membrane. The performance is shown in Table 1.

Embodiment 2

[0091] Dissolve 10.0 g of sulfonated polyimide, 0.20 g of 4,4'-bismaleimide diphenylmethane in 43 g of N-methyl-2-pyrrolidone to form a composition, and coat the composition on PET A wet film with a thickness of 120 μm is obtained on the substrate film, and then dried at 180°C for 30 minutes to completely remove N-methyl-2-pyrrolidone to obtain a dry film, and then soak the dry film in 10% dilute sulfuric acid solution for 16 hours for acidification , after washing the acidified membrane to neutrality with deionized water, dry it at 25° C. and 50% humidity to obtain a polymer electrolyte membrane. The performance is shown in Table 1.

Embodiment 3

[0093] Dissolve 10.0 g of sulfonated polyimide, 0.53 g of 4,4'-bismaleimide diphenylmethane in 43 g of N-methyl-2-pyrrolidone to form a composition, and coat the composition on PET A wet film with a thickness of 120 μm is obtained on the substrate film, and then dried at 180°C for 30 minutes to completely remove N-methyl-2-pyrrolidone to obtain a dry film, and then soak the dry film in 10% dilute sulfuric acid solution for 16 hours for acidification , after washing the acidified membrane to neutrality with deionized water, dry it at 25° C. and 50% humidity to obtain a polymer electrolyte membrane. The performance is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com