Manufacturing method of additive manufacturing integrated shank prosthesis

A technology of additive manufacturing and manufacturing methods, applied in artificial legs, additive processing, prostheses, etc., which can solve problems such as inaccurate model data, complicated manufacturing processes, and inability to repeat manufacturing, and achieve accurate model data, symmetrical aesthetics Good, without the effect of personnel on duty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

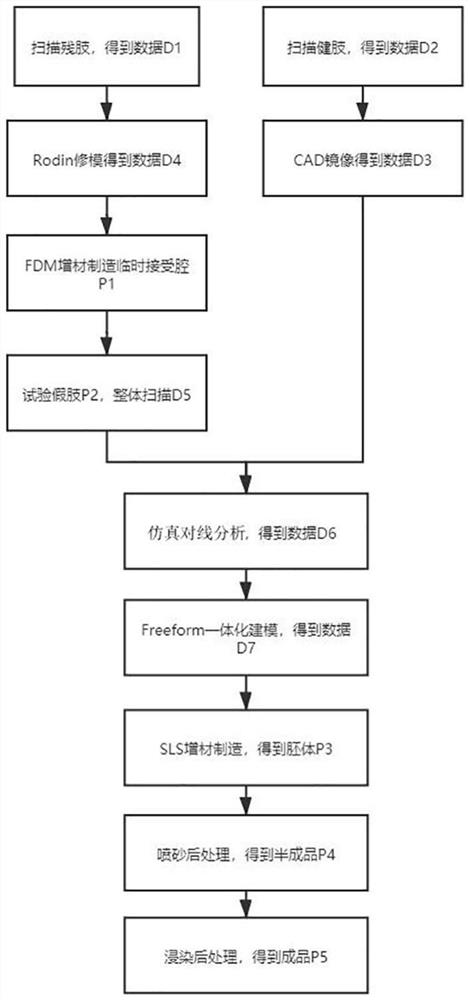

[0028] See figure 1 , the manufacturing method of the integrated calf prosthesis by additive manufacturing of the present invention comprises the following steps:

[0029] Step S10: Scan and take the shape of the residual limb of the patient by using a special medical scanner to obtain 1:1 three-dimensional image data D1 of the residual limb; because the three-dimensional image data D1 is assisted by the patient in the standing functional position and the special shape-taking equipment. It can reduce the shape error caused by human force in the traditional plaster molding process, and it is more suitable for the actual force of the patient when standing with the prosthesis, and the molding process is closer to the full contact load-bearing concept of the residual limb;

[0030] Step S20: Use a special medical scanner to scan and take the shape of the healthy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap