Efficient rotary screen printing machine and application thereof in polyester fabric printing process

A technology of printing machine and rotary screen, applied in general parts of printing machinery, screen printing machine, printing machine, etc., can solve the problems of reduced printing effect, reduced fabric quality, color paste fluidity, and great influence on adhesion. , to achieve the effect of improving the printing effect and improving the printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

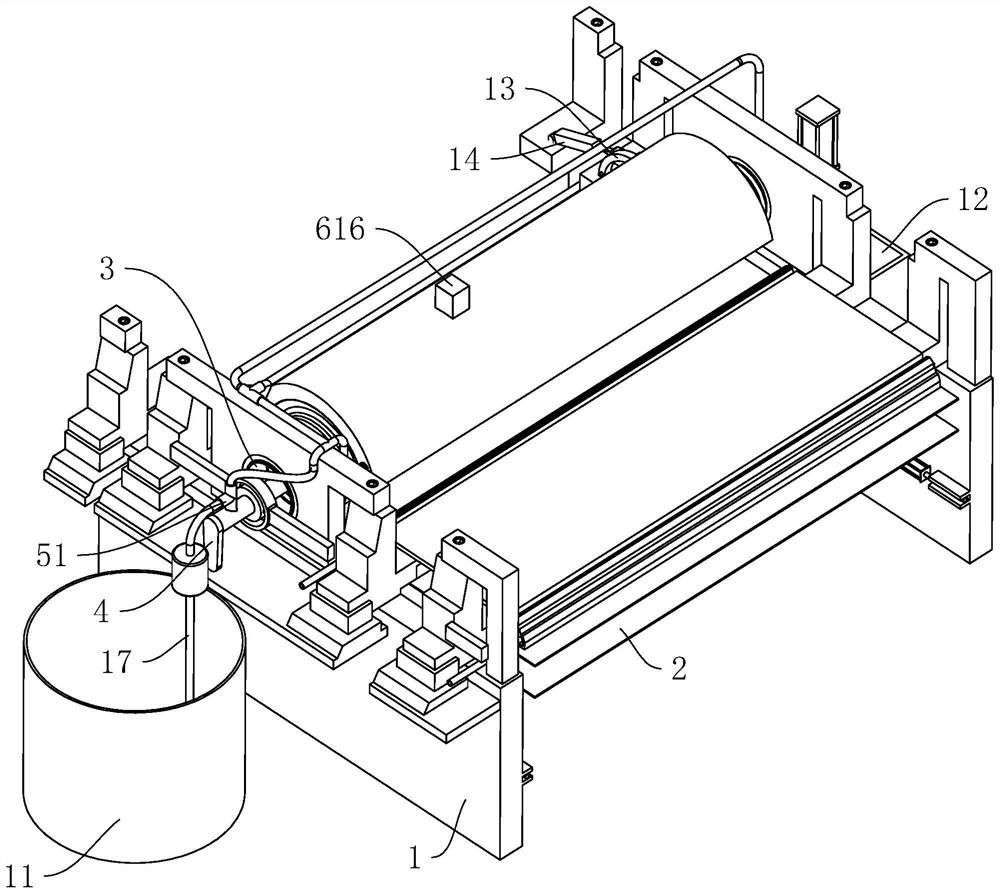

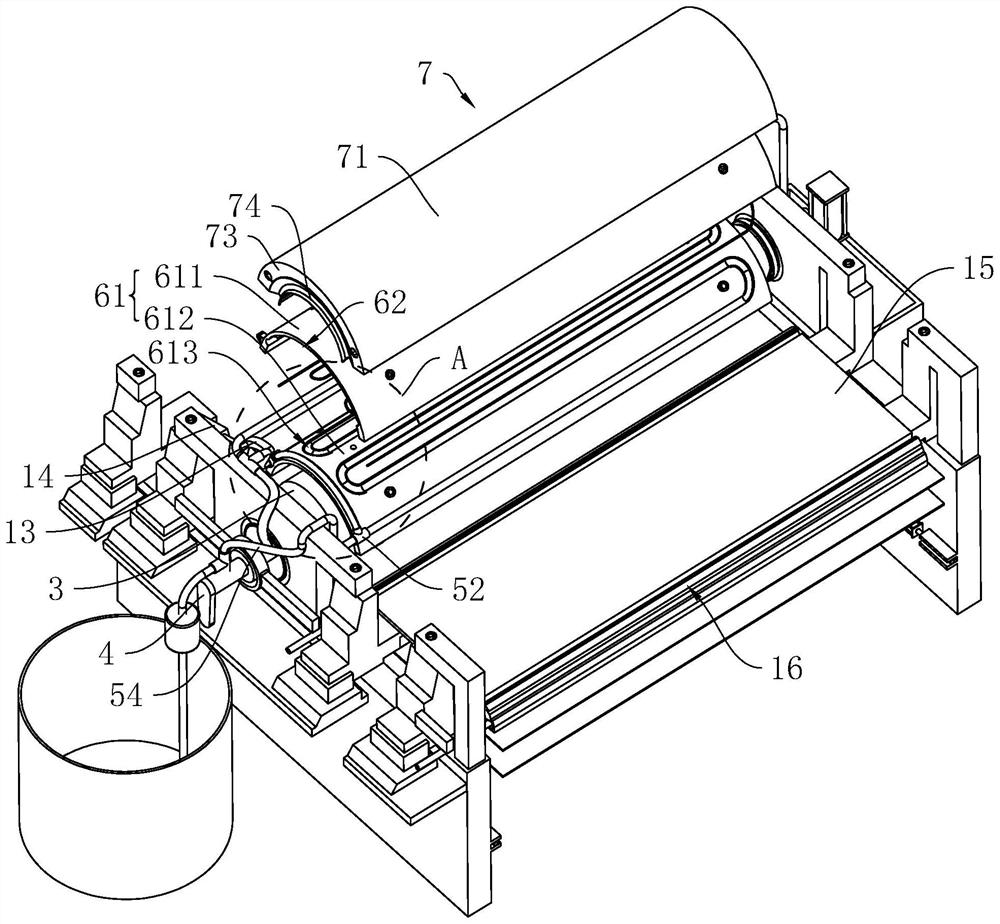

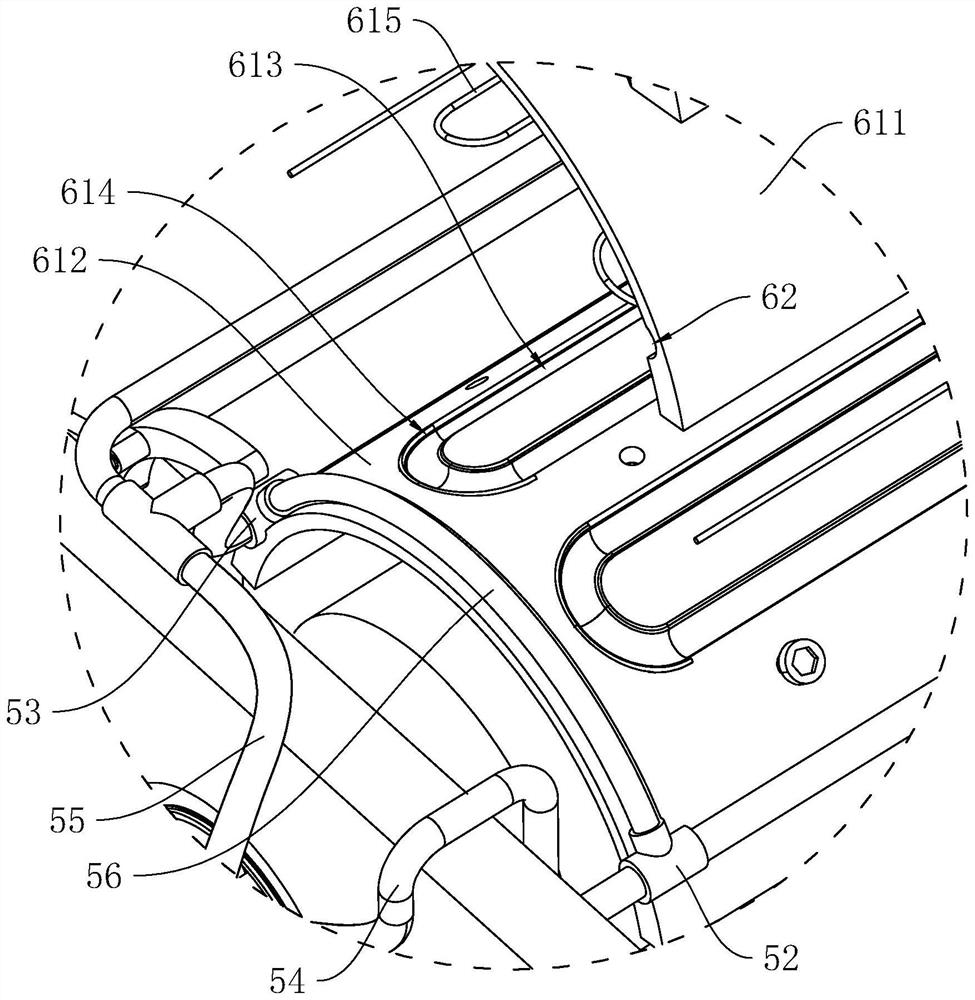

[0036] The following is attached Figure 1-5 The application is described in further detail.

[0037] The embodiment of the present application discloses a high-efficiency rotary screen 3 printing machine, referring to figure 1 , comprising a frame 1, the frame 1 is fixedly installed with a printing platform 2, a rotary screen 3 rolling on the printing platform 2 is installed on the frame 1, the frame 1 is provided with a scraper 4 located in the rotary screen 3, and the scraper 4 It is a hollow tube structure, and the scraper 4 is provided with a strip-shaped hole for the color paste to flow into the cylinder 3 .

[0038] refer to figure 1 A color paste bucket 11 and a color paste recovery bucket 12 are placed on both sides of the frame 1, a first three-way valve 51 is connected to the end of the scraper 4 close to the color paste bucket 11, and one of the ports of the first three-way valve 51 is connected to the scraper 4 , the second branch of the first three-way valve 5...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap