Intelligent high-speed open-width knitting and preshrinking combination machine and processing process thereof

A combined machine and pre-shrinking technology, which is applied to textile processing machine accessories, compressed water, and fabric elongation, can solve problems such as labor waste, reduced fabric processing efficiency, and resource waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

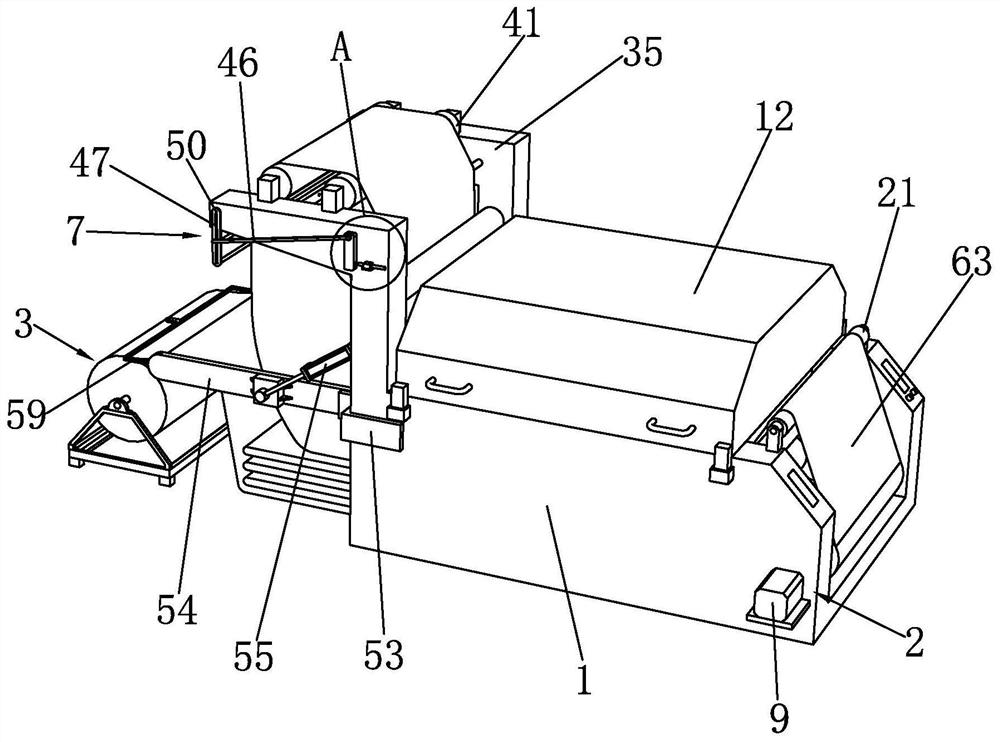

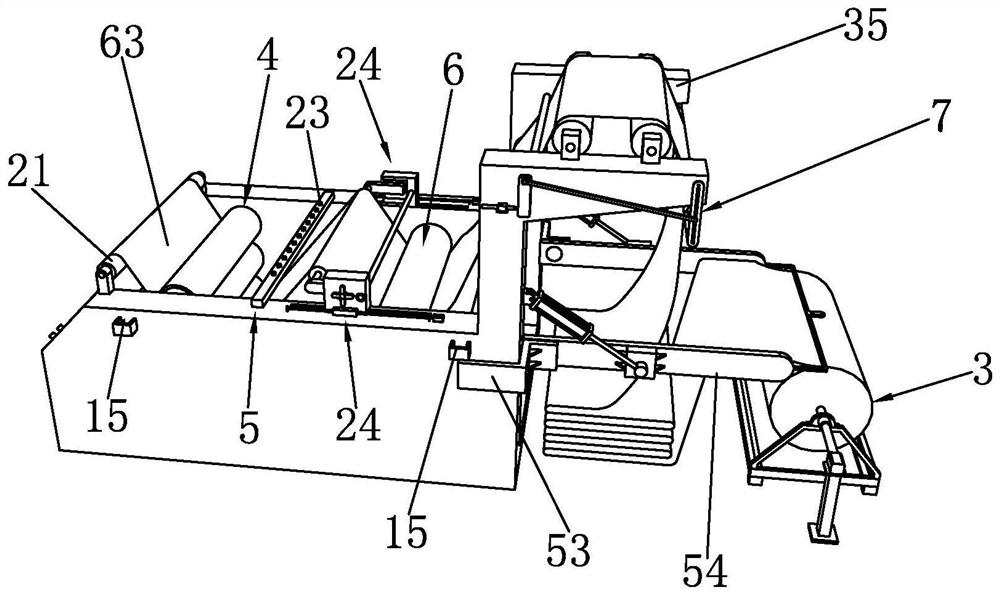

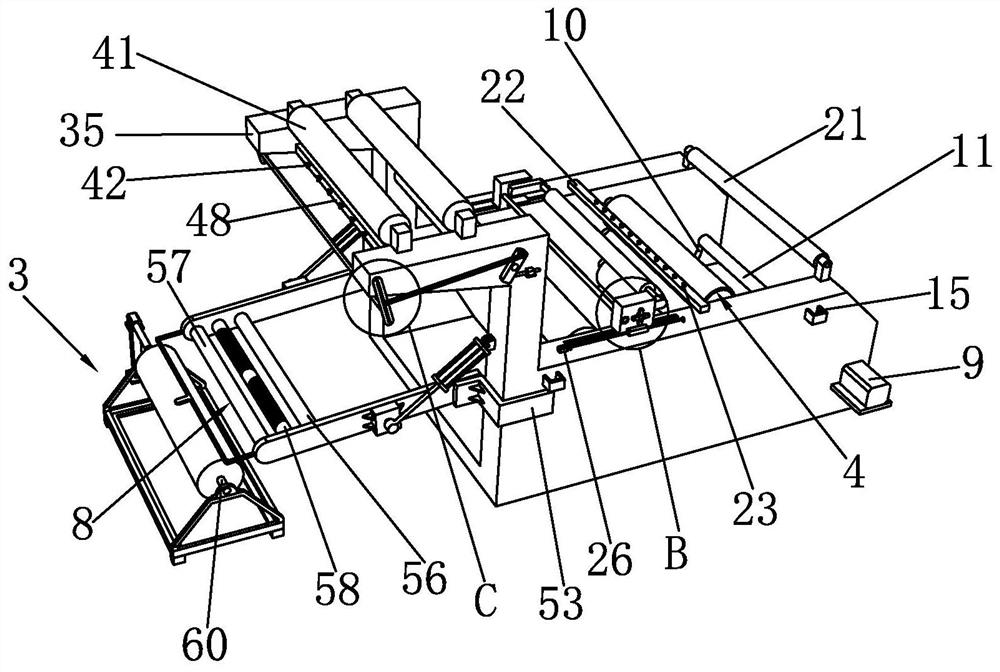

[0040] like Figure 1 to Figure 10 As shown, it is an intelligent high-speed open-width knitting pre-shrinking combined machine of the present invention, including a frame 1, one end of the frame 1 is provided with a cloth feeding assembly 2, and the other end of the frame 1 is provided with a cloth rolling assembly 3, and the cloth feeding assembly 2 and cloth rolling assembly 3 are sequentially provided with a calendering assembly 4, a humidifying assembly 5, a shrinking assembly 6, a drying assembly 7, and a tenter pressing assembly 8, and the tenter pressing assembly 8 is matched with the cloth rolling assembly 3 .

[0041] The cloth feeding assembly 2 includes a driving motor 9, a bracket 10 and a feed roller 11, the driving motor 9 is arranged on one side of the frame 1, the bracket 10 is arranged on both sides of the frame 1, and the bracket 10 is placed on the feeding roller. At both ends of the roller 11 , the drive motor 9 drives the feed roller 11 to rotate, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com