Rapid manufacturing pulp molding mold

A technology of pulp molding and mould, which is applied in the direction of textiles and papermaking, and can solve the problems of inconvenient molding removal and low molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

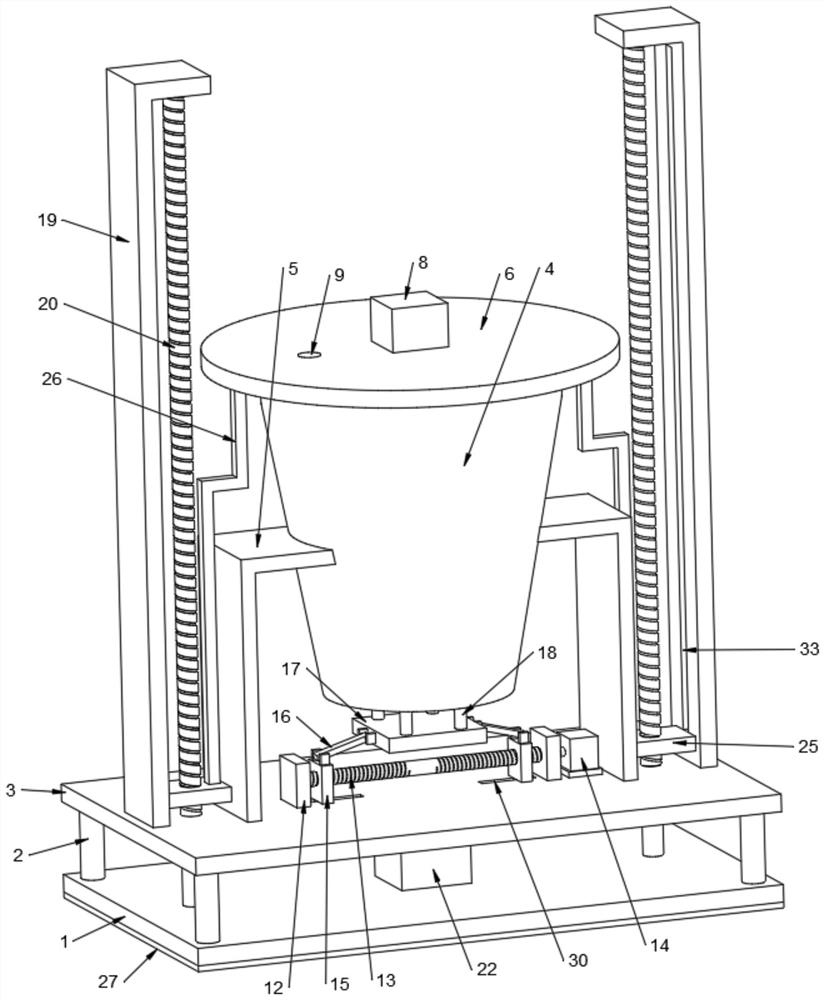

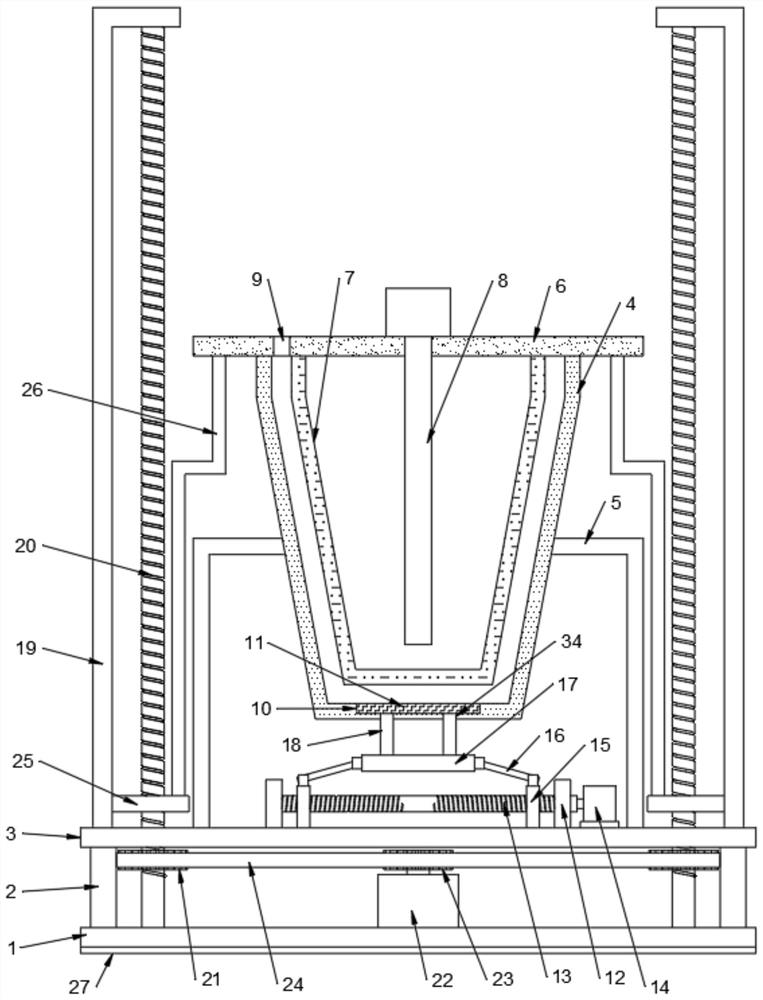

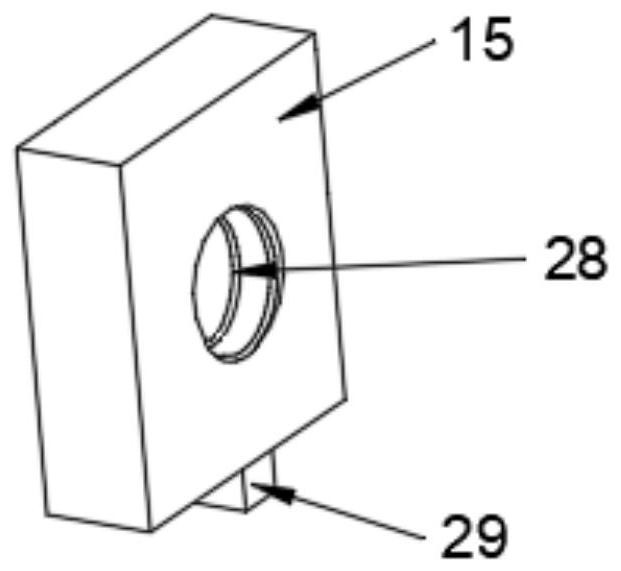

[0024]SeeFigure 1-4The present invention provides the following technical solutions: a rapid manufacturing pulp molding die, including the base 1, the top symmetry of the base 1 is fixed to four columns 2, and the base 1 is provided with a support plate 3, the top of the column 2 is The bottom of the support plate 3 is fixed, and the first mold 4 is provided above the support plate 3, and the surface of the first mold 4 is fixedly fixed having the L-type connecting plate 5, the bottom of the L-type connecting plate 5 is fixed to the top of the support plate 3. Connecting, the top of the first mold 4 is bonded to the cover 6, and the bottom of the cover plate 6 fixes a second mold 7, and the inside of the second mold 7 is attached, and the upper portion of the cover plate 6 is opened. 9, the bottom inner wall of the first mold 4 is provided with a placement tank 10, and the inner portion of the placing groove 10 is provided, and the top symmetry of the support plate 3 is symmetricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com