Embossing plate roller suitable for embossing of various materials

A technology of embossing and plate roller, which is applied in decorative art, embossed decorative parts, etc., can solve the problems of short-term shutdown, affecting the efficient and normal processing of materials, etc., and achieve the effect of improving work efficiency, reducing human intervention, and improving assembly and disassembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

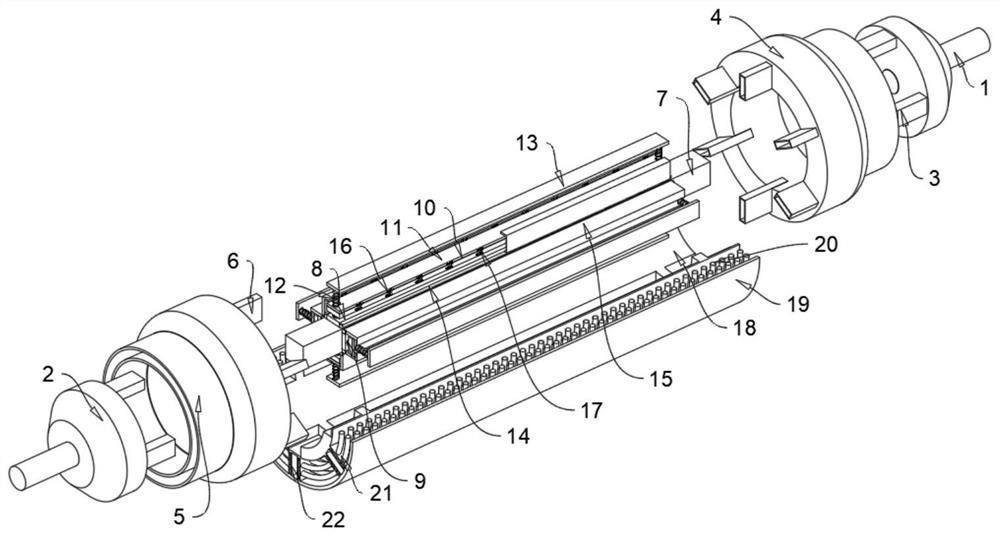

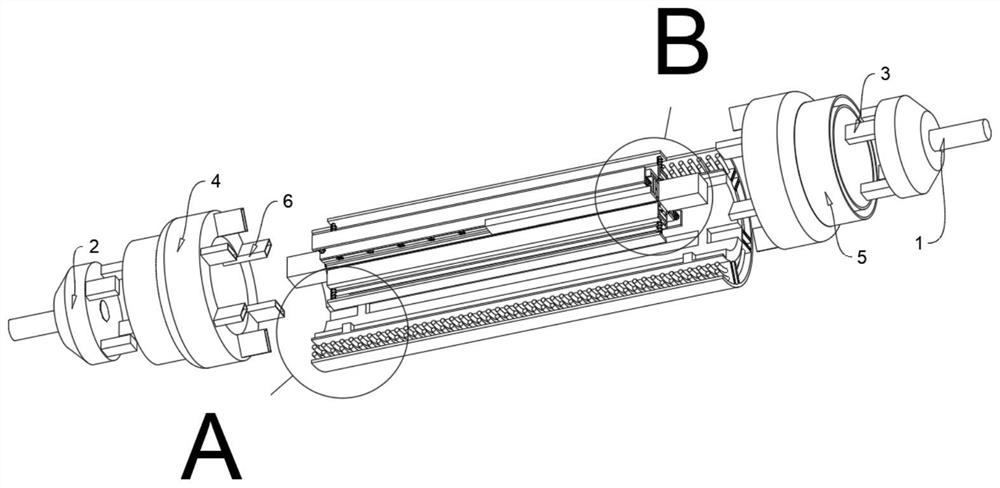

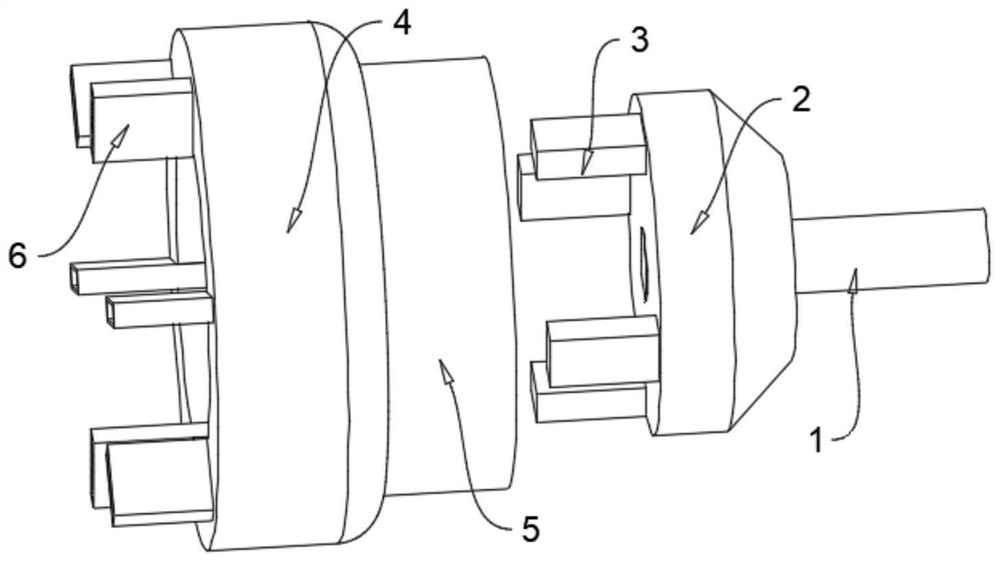

[0032] Example: Please refer to Figure 1 to Figure 8 :

[0033]The present invention proposes an embossing plate roller suitable for embossing various materials, including: an installation shaft 1, and there are two installation shafts 1, and one side of the two installation shafts 1 is fixedly connected with a seat body 2 , the installation shaft 1 is connected with the bearing shaft 7, and the two installation shafts 1 are fixedly connected to the left and right sides of the bearing shaft 7 respectively, and are fixedly connected to the limit block 3 on one side of the seat body 2 in an annular array, and the limit block 3 For limiting the inner layer 18, the outer side of the seat body 2 is also sleeved with a collector seat 4, and the outer peripheral surface of the inner layer 18 is fixedly connected with a partition 21 in an annular array, and is connected to the roller layer 19 through the partition 21. Connection, every two adjacent partitions 21 arranged on the insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com