Packing box leading-in machine

A packing box and guide box technology, applied in the direction of packaging, etc., can solve the problems of slow packing process and high labor intensity of workers, and achieve the effect of low cost, simple structure, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

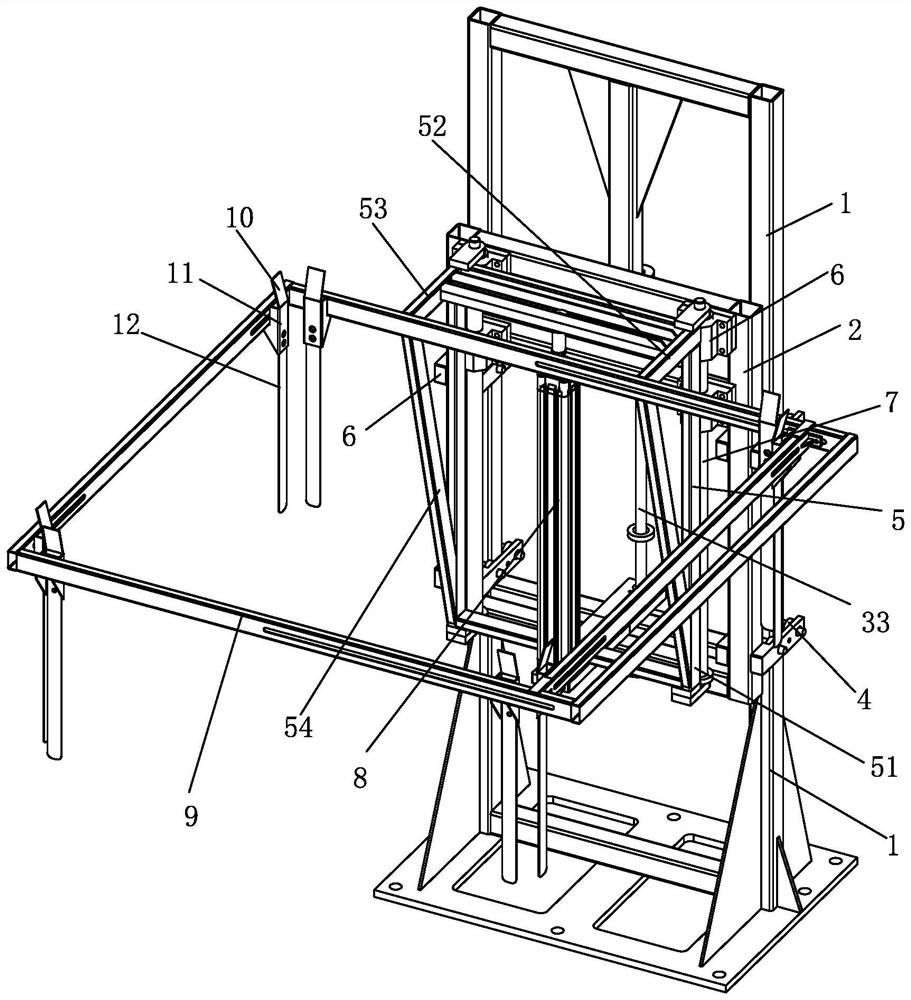

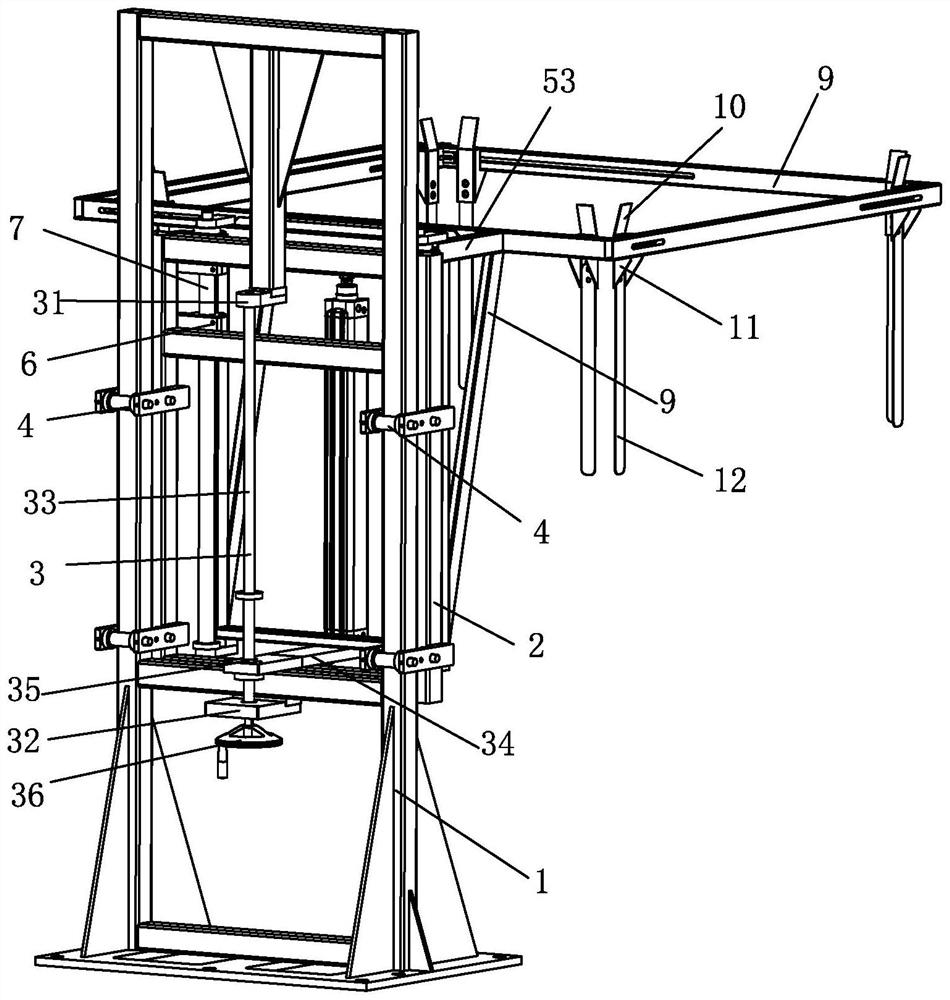

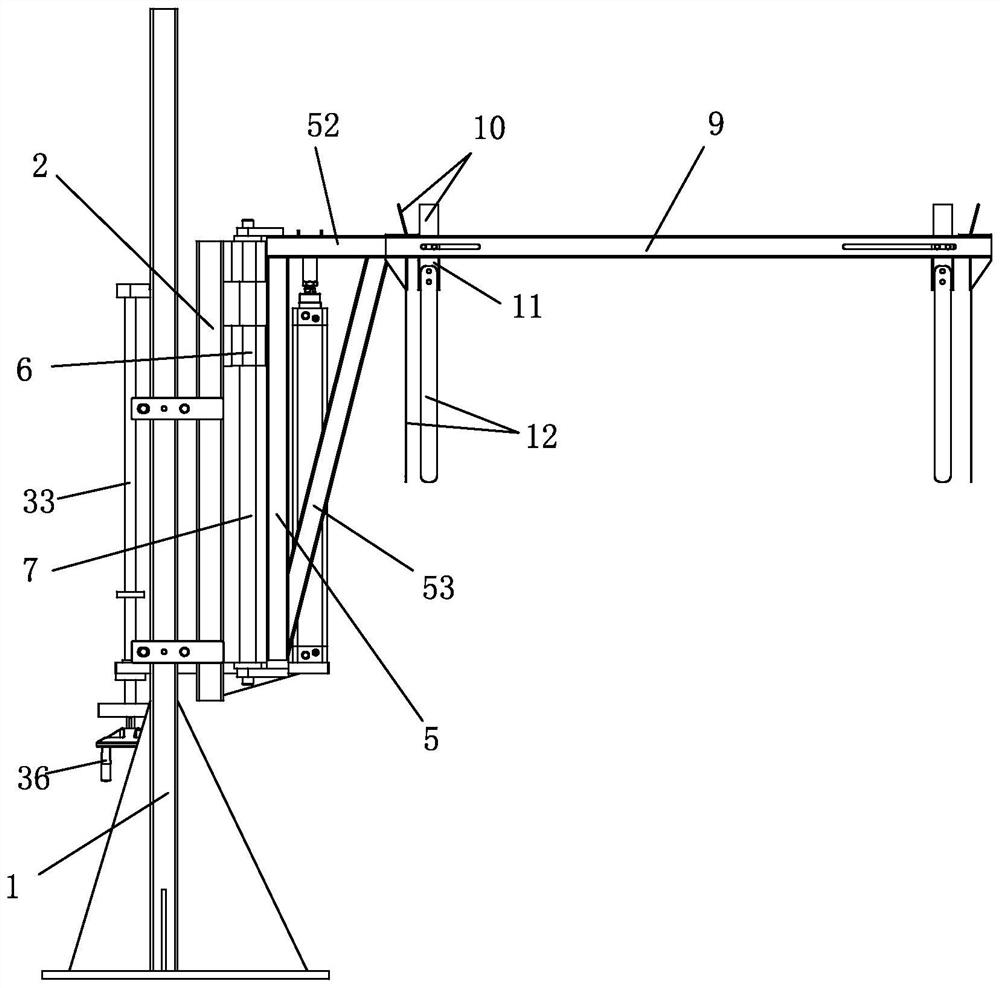

[0016] The present invention will be further described below in conjunction with accompanying drawing:

[0017] A machine for introducing packing boxes, which is characterized in that it includes a support frame 1, a first lifting frame 2 that can be raised and lowered on the support frame 1, and a hand screw assembly 3 that drives the first lifting frame 2 to lift And the sliding wheel assembly 4, the first lifting frame 2 is provided with the second lifting frame 5 that can be lifted on the first lifting frame 2, the front of the first lifting frame 2 is provided with a bearing seat 6, and the back of the second lifting frame 5 is provided The axle 7 that cooperates with bearing seat 6 is arranged, also be provided with push-off cylinder 8 on the first lift frame 2, the output end of push-off cylinder 8 is fixed with the upper end of the second lift frame 5, and the front of the second lift frame 5 is also provided with There is a guide box frame 9, and the guide box frame 9...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap