Heat exchange tube elbow distributing mechanism

A material distributing mechanism and heat exchange tube technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems that the quality of the arrangement cannot be guaranteed, it is inconvenient to clamp multiple elbows at the same time, and the volume of the mechanism increases, etc., to achieve The effect of simple structure, few parts and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

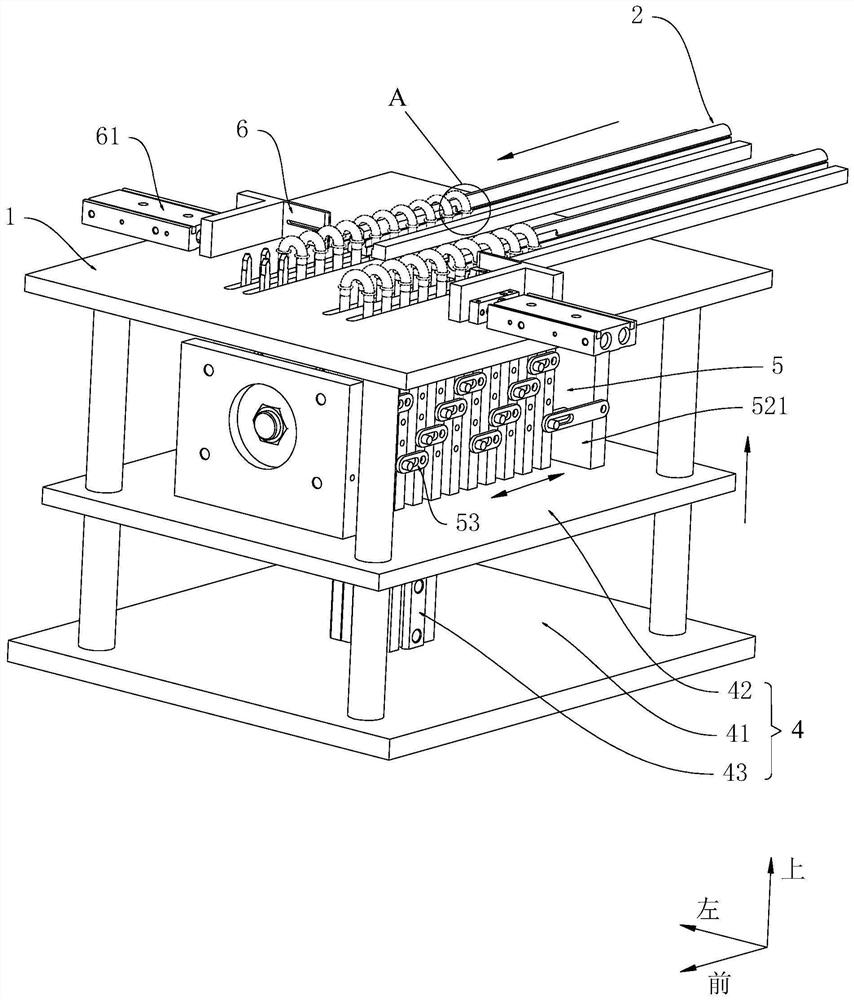

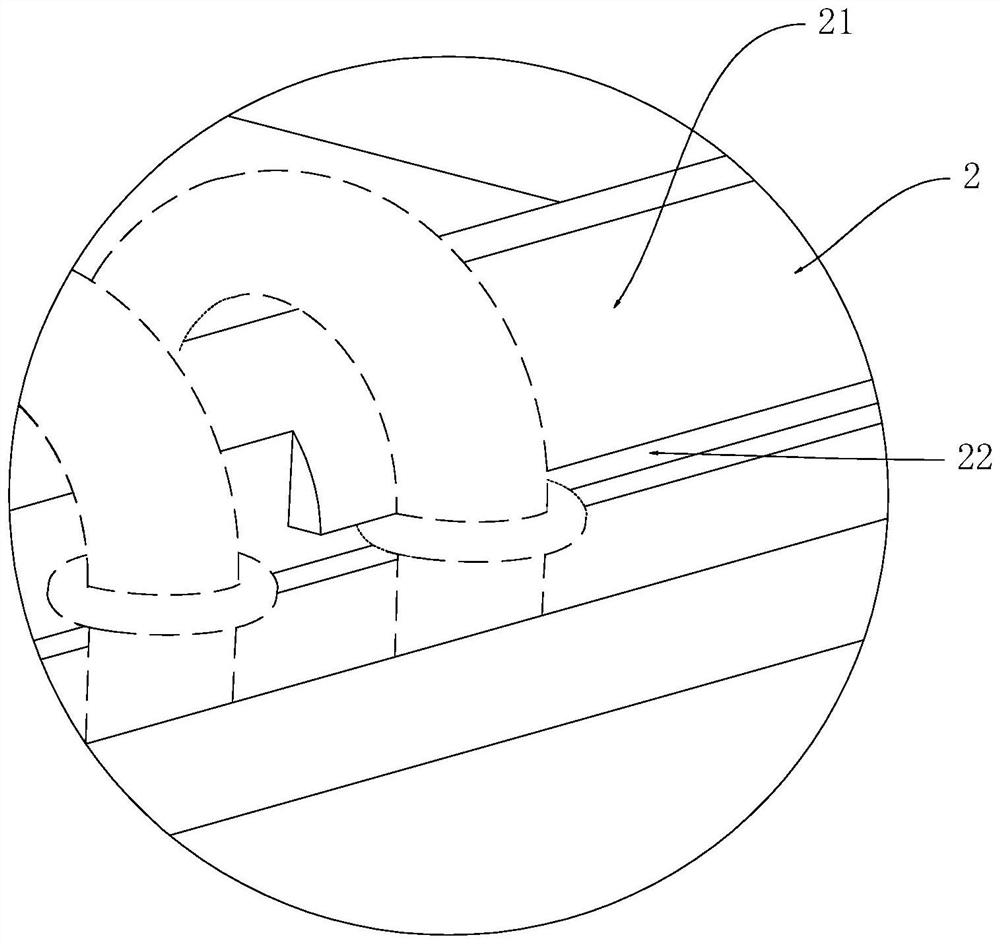

[0022] Such as Figure 1 to Figure 3 The heat exchange tube elbow material distributing mechanism shown includes an upper fixed platform 1, which is provided with a conveying track 2 for transporting neatly arranged U-shaped elbows, and the U-shaped elbows are mounted on Slide back and forth on the conveying track 2, and the conveying track 2 can be one or more arranged side by side;

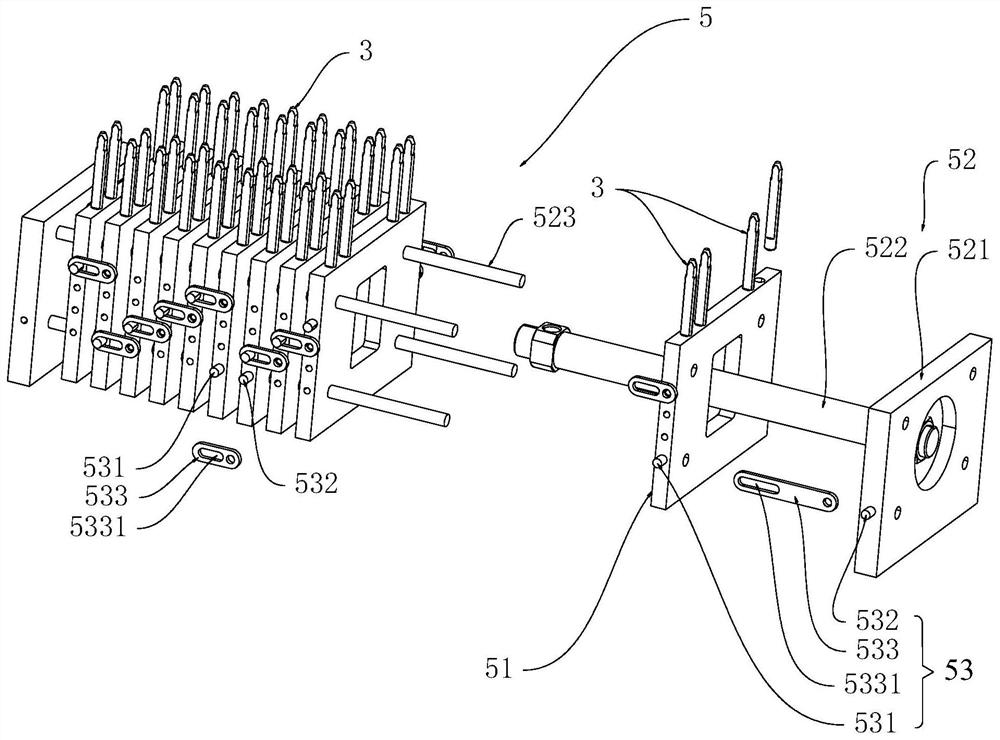

[0023] The front end of the conveying track 2 is provided with several sets of pin assemblies, and each set of pin assemblies includes two pins 3 arranged in the left and right directions, and a lifting structure 4 that can drive the pin assemblies to lift is provided below the pin assemblies. A spacing adjustment structure 5 that can adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com