Hazardous chemical gas tank intelligent management cabinet and management method based on NFC

A technology for managing cabinets and gas tanks, applied in container discharge methods, container filling methods, fixed-capacity gas storage tanks, etc., can solve problems such as high risk, inability to detect and replace in time, pipeline rupture, etc., to improve supervision. strength, to achieve automatic recording, to ensure the effect of stable placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

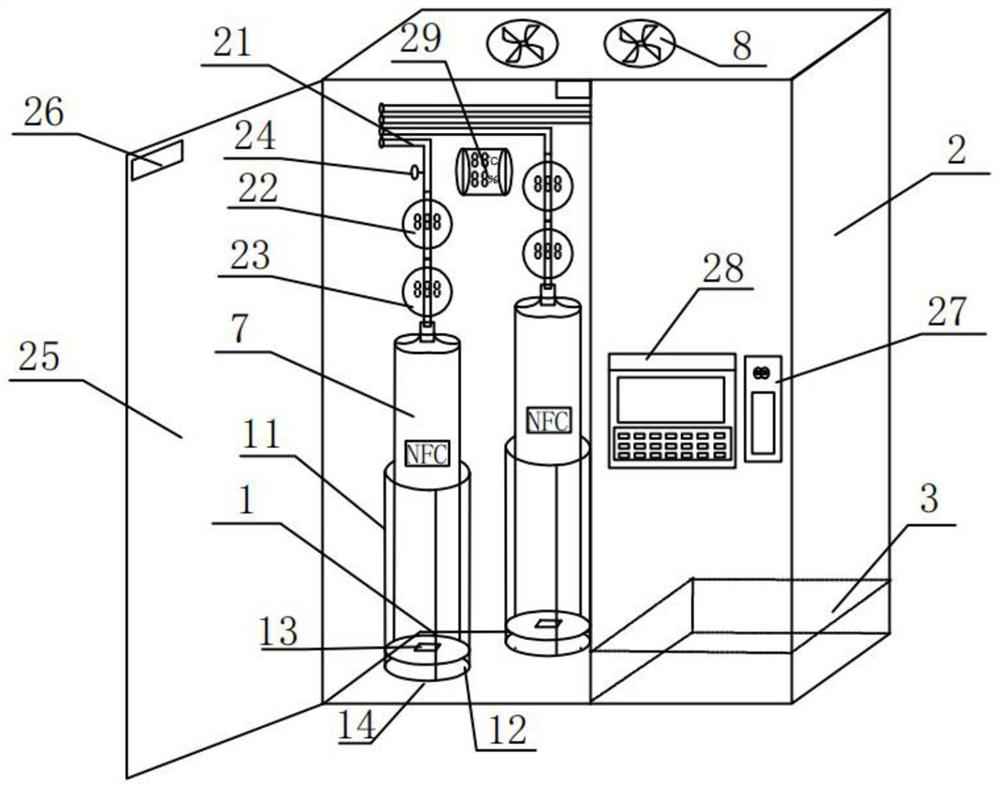

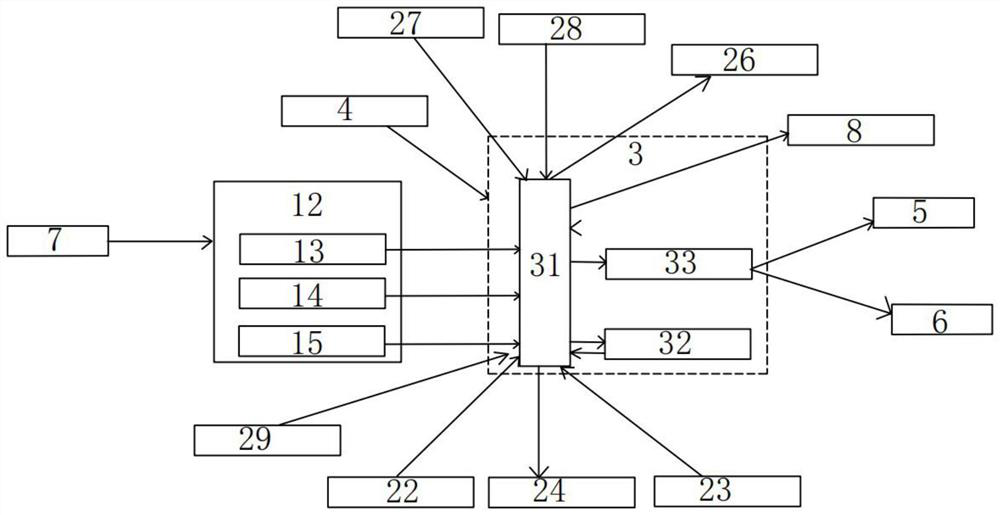

[0027] see figure 1 with figure 2 , is an embodiment of an NFC-based intelligent management cabinet for hazardous chemical gas tanks provided by the present invention. The NFC-based intelligent management cabinet for hazardous chemical gas tanks includes several support frames 1 and a cabinet body 2, and the support frame 1 It is fixed on the bottom of the cabinet body 2, and is used to place several gas tanks 7, wherein a cylindrical support fence 11 is arranged on the upper end of each support frame 1, and the height of the support fence 11 exceeds 1% of the height of the gas tank 7. / 2, to ensure that the gas tank 7 can be effectively supported, a support platform 12 is provided at the bottom of each support frame 1, and an NFC card reader 13 and a weighing unit 14 electrically connected to the control unit 31 are provided on the support platform 12, The NFC card reader 13 is used to pair with the NFC identity card on the gas tank 7 to analyze the information of the gas t...

Embodiment 2

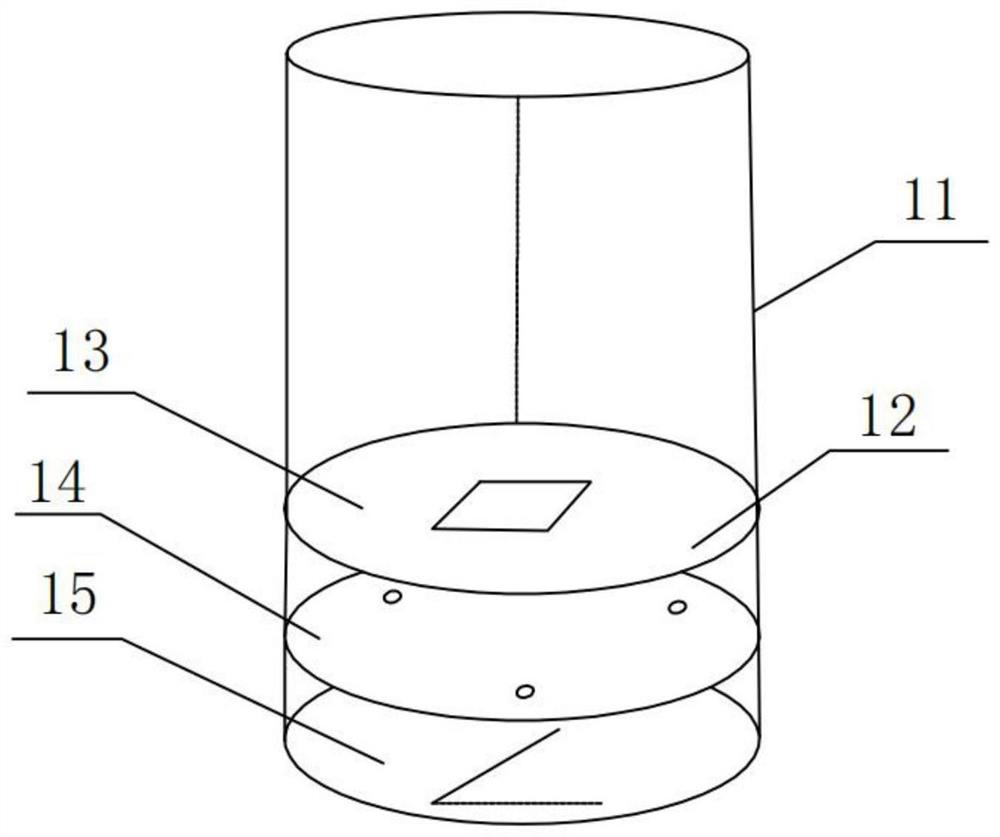

[0036] Such as image 3 As shown, the biggest difference between this embodiment and the first embodiment is that the support platform 12 is also provided with an inclination sensor 15 electrically connected to the control unit 31. The inclination information of the back and the horizontal plane. Because the gas tank 7 that is full of gas is usually heavier, it often occurs in the common gas tank management cabinet that the whole support frame is overturned due to too much load, causing major personal and property accidents. Therefore, in this embodiment, the inclination sensor 15 is provided on the support platform 12. The angle sensor 15 can measure the posture of the gas tank 7 in real time, and judge whether the gas tank 7 and the support frame 1 are tilted. Under normal circumstances, the gas tank 7 is placed in a vertical state on the support platform 12, and a tilt threshold is set in the angle sensor 15. If the gas tank 7 is tilted, if the angle with the horizontal pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com