Split encoder capable of guaranteeing assembly precision

An assembly accuracy and encoder technology, applied in the physical field, can solve the problems that the encoder cannot guarantee the assembly accuracy, and achieve the effects of eliminating strict restrictions, ensuring installation accuracy, and improving angle measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

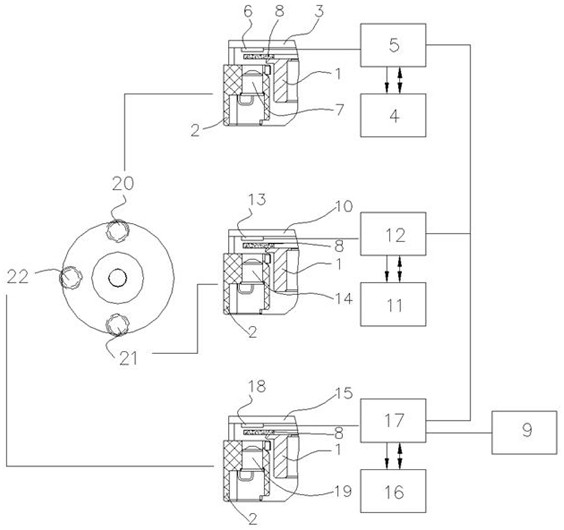

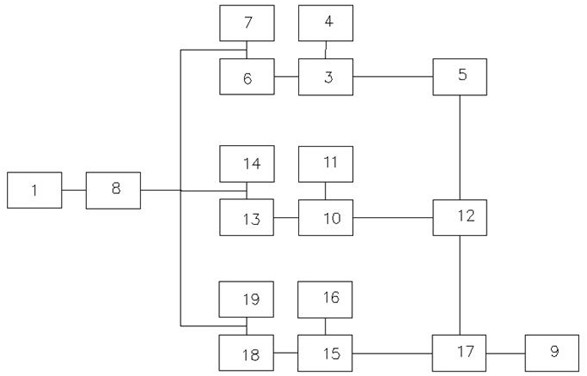

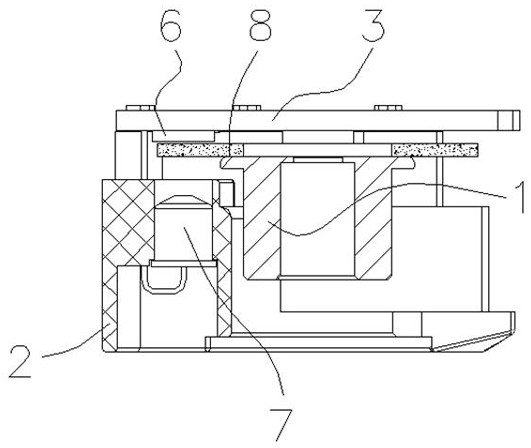

[0016] Such as figure 1 , figure 2 and image 3 As shown, a split encoder capable of ensuring assembly accuracy of the present invention includes an encoder main shaft 1 and a base 2, the encoder main shaft 1 is arranged in the base 2, and a code disc 8 is fixedly arranged on the encoder main shaft 1 , the base 2 is provided with a first unit basic function block 20 and a second unit basic function block 21 along the circumferential direction, and a first unit basic function block 20 and the second unit basic function block 21 are provided with a first unit basic function block 21 Three-unit basic function block 22;

[0017] The encoder spindle 1 is connected as a whole with the code disc 8 by glue, and is in an independent state. When measuring, it is installed on the measured shaft end by an assembly auxiliary tool, and can rotate relative to the base 2 .

[0018] The first unit basic function block 20 includes a first PCBA functional block 3, a first digital memory 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com