Electromechanical brake actuator and curved disc

A disc brake and actuator technology, applied in the direction of brake actuators, brakes, brake types, etc., can solve the problems of reduced service life, damage to the functionality of brake actuators, etc., and achieve easy maintenance and less structural complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

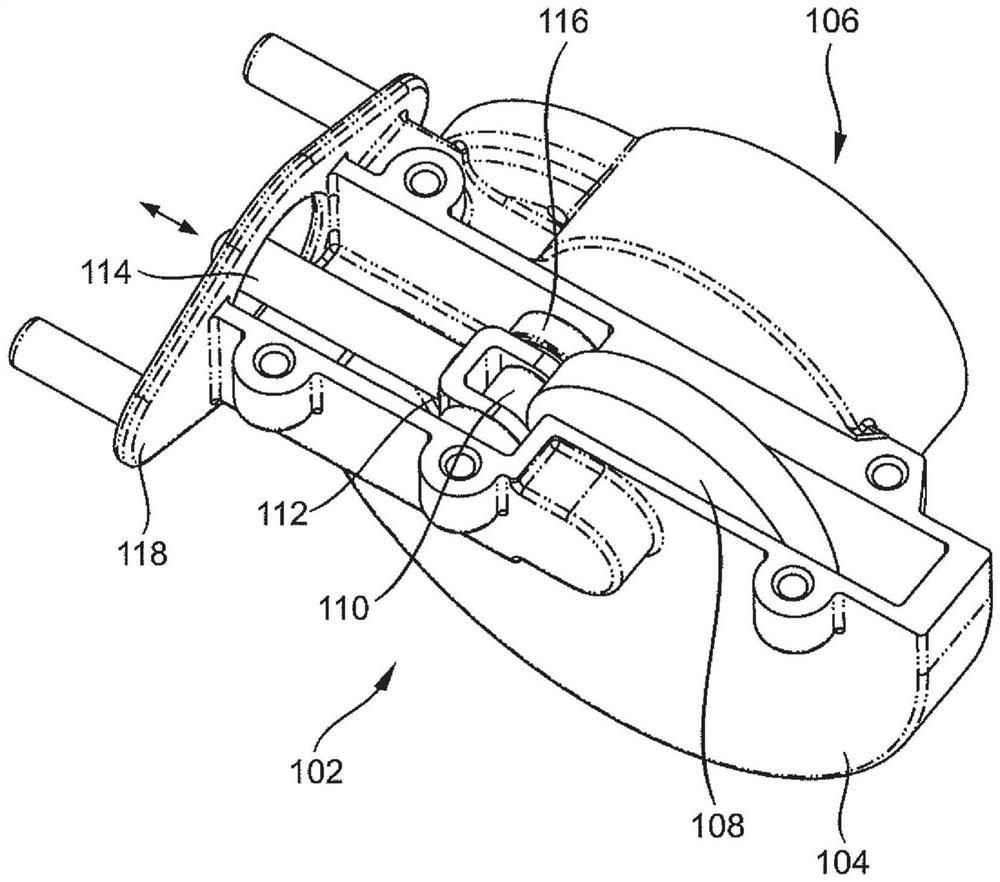

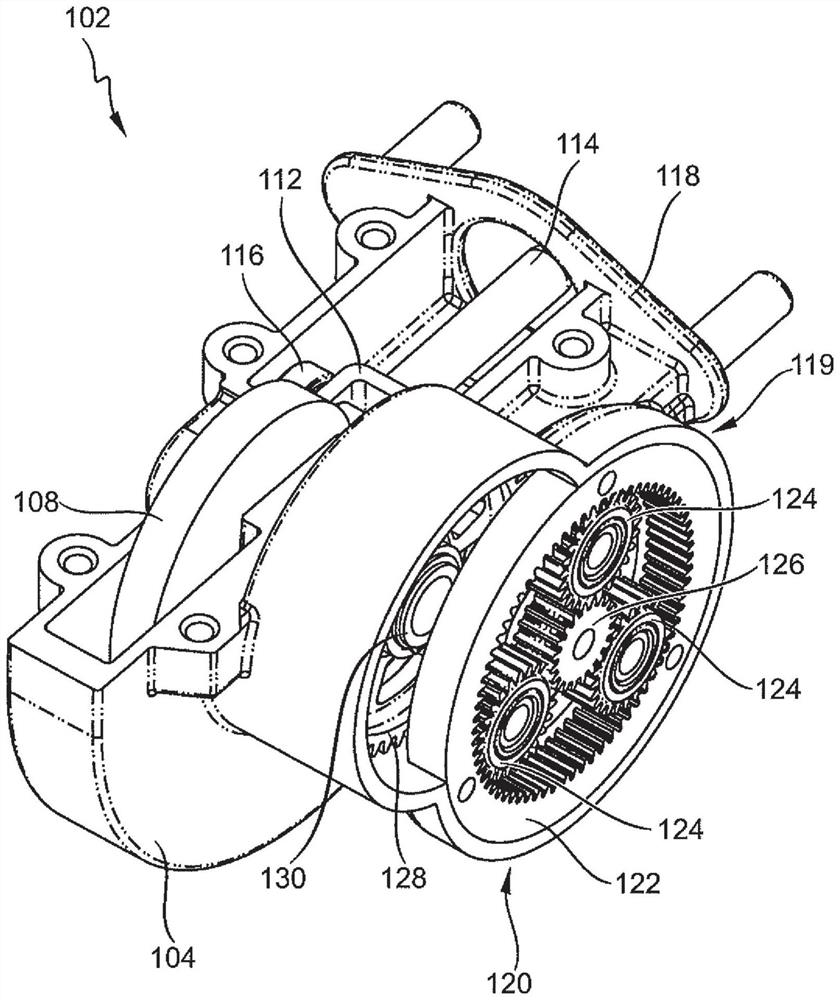

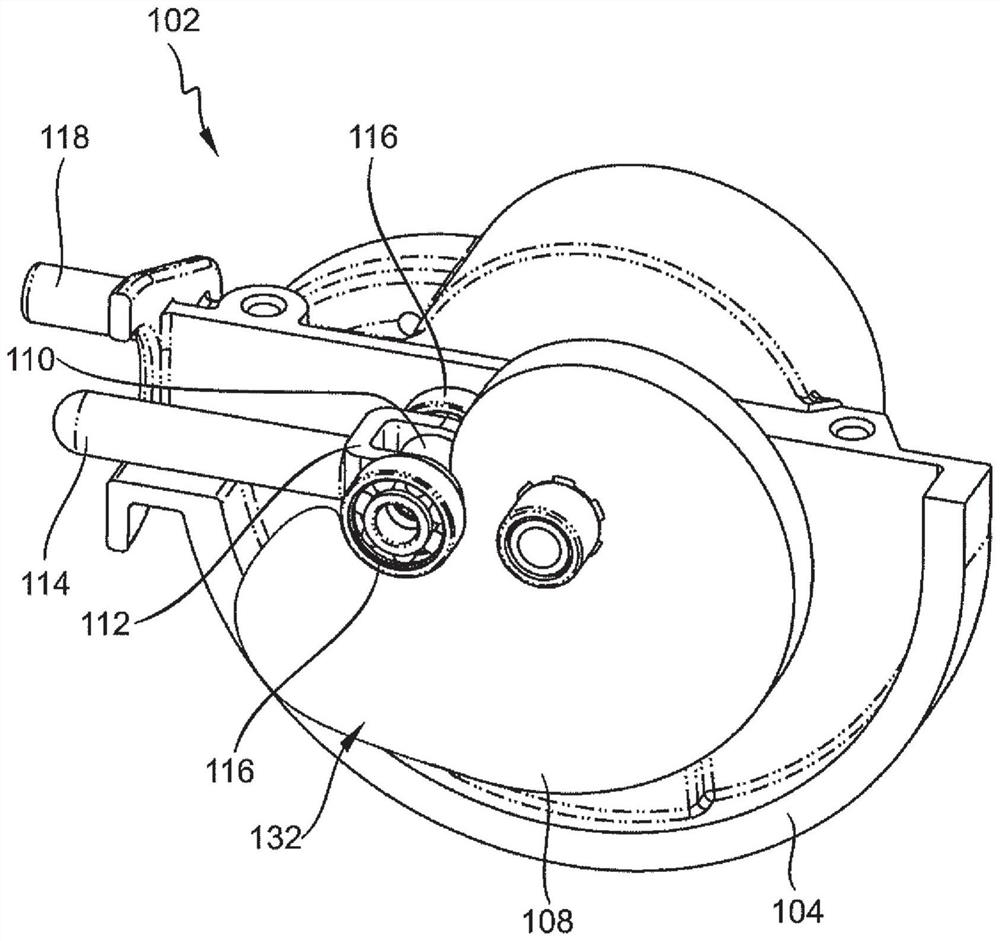

[0069] figure 1 An electromechanical actuator 102 is shown with a housing 104 . The actuator 102 has an electric motor 106 . The drive torque of the electric motor 106 is via the housing (see figure 2 ) is passed to the curve disk 108. Curved disk 108 serves to transmit the rotational movement of curved disk 108 non-linearly to brake tappet 114 .

[0070] The brake tappet 114 can deviate, in particular linearly, in the direction of the arrow shown. The brake tappet 114 has a tappet head 112 at its end facing the curve disk 108 . The tappet head 112 surrounds a rolling body 110 mounted by means of a bearing 116 . The rolling elements 110 slide on the peripheral surface of the curved disk 108 . Thus, a conversion of the rotational movement of the curved disc 108 into a linear movement of the brake tappet 114 is achieved. The electromechanical actuator 102 is in particular connectable to a brake (not shown) via a connection section 118 .

[0071] exist figure 2 The alr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com