Pig feed mixed fermentation processing method and processing device thereof

A technology of mixed fermentation and processing equipment, which is applied in the field of pig feed, can solve the problems of insufficient alkali solution content and incomplete soaking of straw, and achieve the effect of avoiding too low temperature and solving insufficient content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

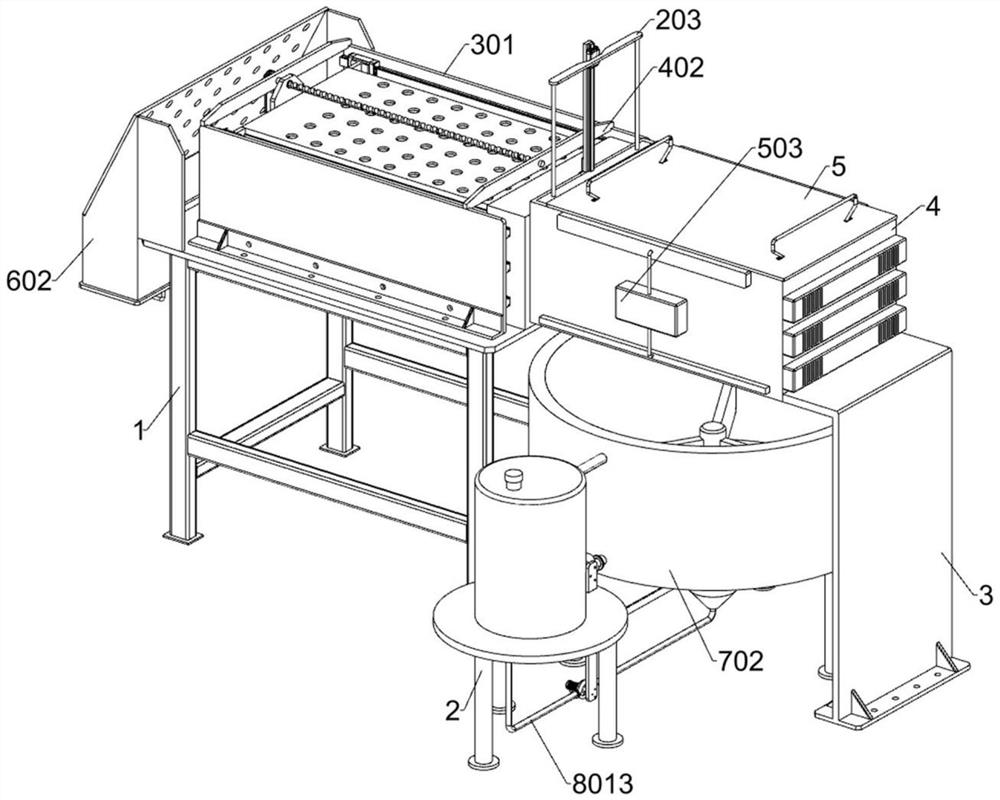

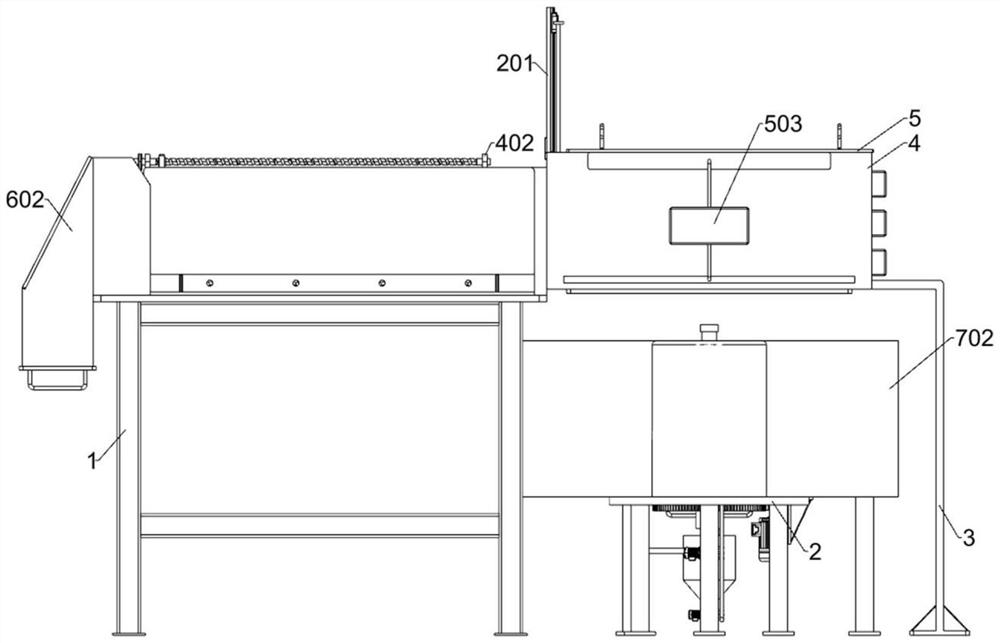

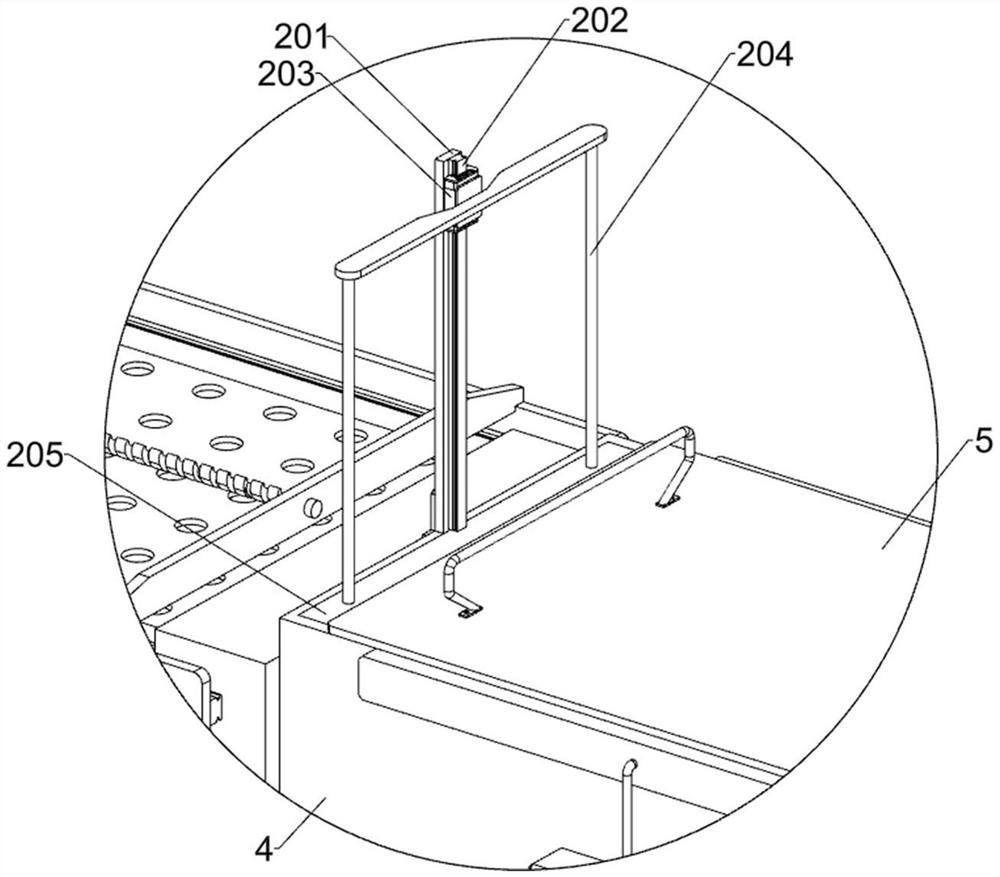

[0050] A processing device for mixed fermentation of pig feed, such as Figure 1-8 As shown, it includes a first support platform 1, a second support platform 2, a support frame 3, a soaking box 4, a top cover 5, an anti-blocking component, a layered component, a drying component, a circulation component, a cleaning component and a first heat preservation component. Components; the second support platform 2 is installed on the right side of the front side of the first support platform 1; the support frame 3 is installed on the right side of the first support platform 1; the layered component is installed on the upper middle of the first support platform 1; the middle part of the layered component A drying component is installed; the drying component is connected to the first support platform 1; a soaking box 4 is installed between the layered component and the support frame 3; a top cover 5 is inserted on the upper side of the soaking box 4; the left side of the soaking box 4 ...

Embodiment 2

[0057] On the basis of Example 1, such as Figure 1-2 and Figure 9 As shown, the cleaning assembly includes a bellows 601, a first storage box 602, a sieve plate 603, a limit plate 604 and a second bottom cover 605; three bellows 601 are connected to the right side of the soaking box 4; A first storage box 602 is connected; a sieve plate 603 is welded on the upper side of the first storage box 602; a limit plate 604 is welded on the right front and right rear of the first storage box 602; two limit plates 604 The lower sides are in contact with the first supporting platform 1 ; the second bottom cover 605 is plugged into the lower side of the first storage box 602 .

[0058] During the soaking and drying process, part of the stalks will fall on the inner side of the partition frame 305. After the soaked stalks are transported to the first thermal insulation component, the three bellows 601 will be activated, and the three bellows 601 will blow to the left at the same time, s...

Embodiment 3

[0060] On the basis of Example 2, such as Figure 1-2 and Figure 10-13 As shown, the first heat preservation assembly includes a support column 701, a stirring cabin body 702, a third pipeline 703, a heater 704, a fourth pipeline 705, a third connecting plate 706 and a first water pump 707; The support column 701; the upper side of the three support columns 701 is welded with a stirring cabin 702; the inside of the stirring cabin 702 is interspersed with a third pipeline 703; the upper middle part of the second support platform 2 is fixed with a heater 704; The input end is connected with the third pipeline 703; the output end of the heater 704 is communicated with the fourth pipeline 705; the rear side of the second support platform 2 is interspersed with the third connecting plate 706; the upper side of the third connecting plate 706 is fixedly connected with the A water pump 707 ; the input end of the first water pump 707 is connected with the fourth pipeline 705 ; the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com