Environment-friendly non-toxic false tooth and manufacturing method thereof

A manufacturing method and technology for dentures, which are applied in medical science, dentistry, dental prostheses, etc., can solve problems such as low applicability, strong foreign body sensation in the patient's mouth, and great pain in the patient's mouth, and achieve a guaranteed position, improved comfort, and guaranteed The effect of gripping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

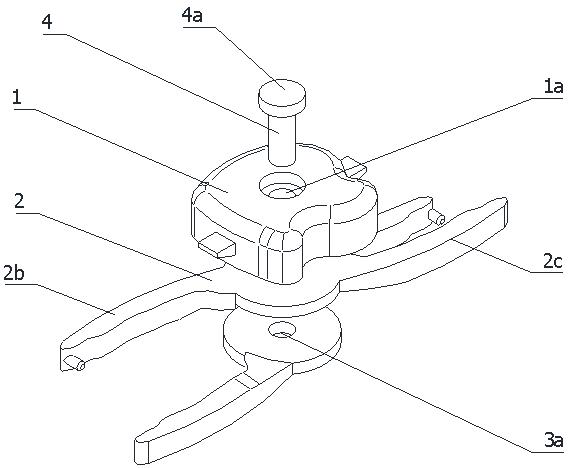

[0055] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0056] like Figure 1 to Figure 5 As shown, this application provides:

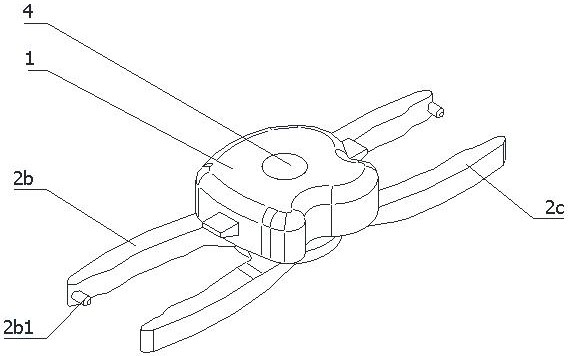

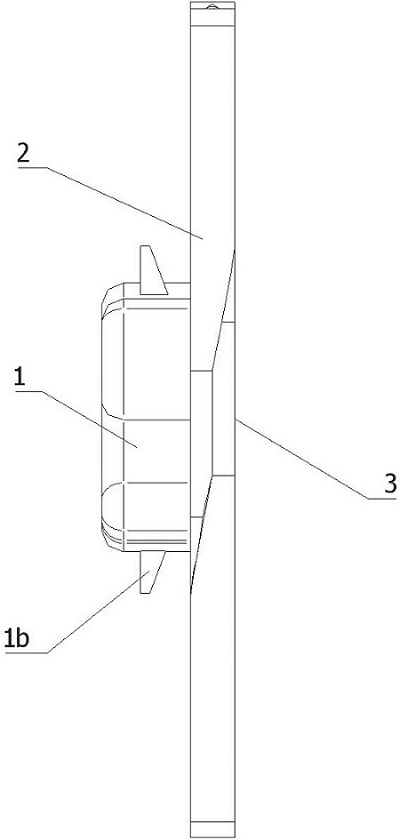

[0057] An environmentally friendly and non-toxic denture, comprising a dental crown 1 that matches the size of the residual tooth, the center of the dental crown 1 is provided with a first threaded hole 1a, the first threaded hole 1a penetrates the dental crown 1 up and down, and the bottom of the dental crown 1 is provided with a threaded hole 1a. The first denture bracket 2 and the second denture bracket 3, the first denture bracket 2 is provided with a second threaded hole 2a, the second denture bracket 3 is provided with a third threaded hole 3a, the first threaded hole 1a, The second threaded hole 2a and the third threaded hole 3a have the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com