Novel feeding assembly of full-automatic anaerobic glue injection machine

A glue injection machine, fully automatic technology, applied to the device and coating of the surface coating liquid, can solve problems such as unfavorable automation of production, adjustment of materials that cannot be reclaimed, etc., to improve automation, ensure speed, The effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

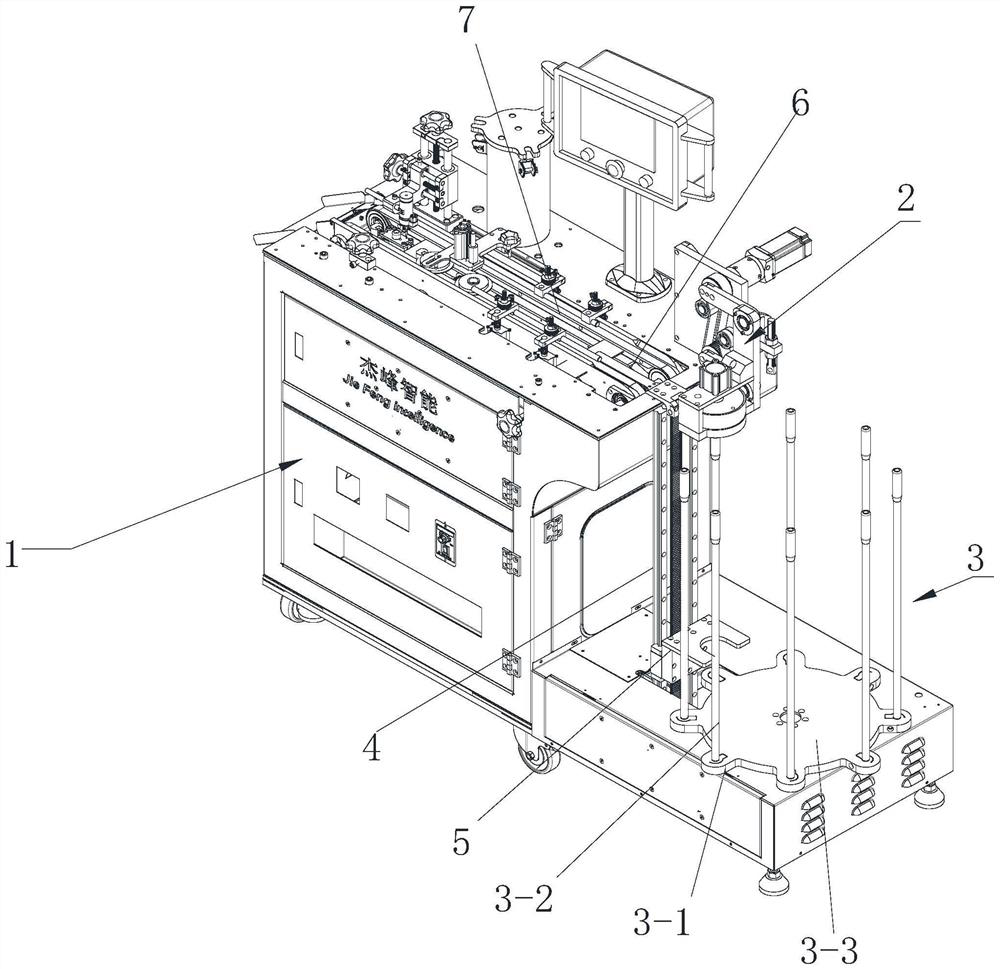

[0029] Such as Figure 1 to Figure 3 As shown, the present invention discloses a new type of feeding assembly of a fully automatic anaerobic glue injection machine. In view of the current filter end cap feeding, the staff needs to take the end caps to the feeding area and place them one by one. Regarding the problem of conveyor belt 7, this scheme changes the feeding area to automatic feeding through reasonable design, which can greatly increase the processing efficiency and reduce the participation of personnel. The specific scheme design is as follows:

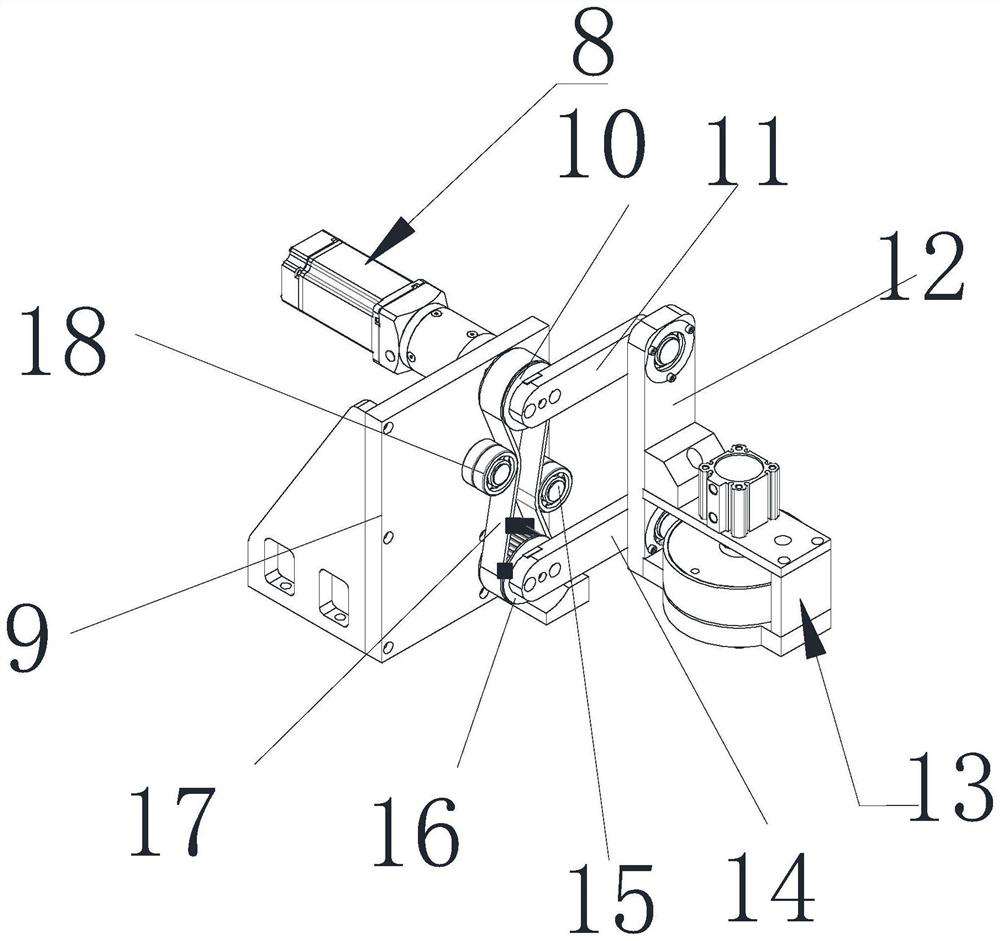

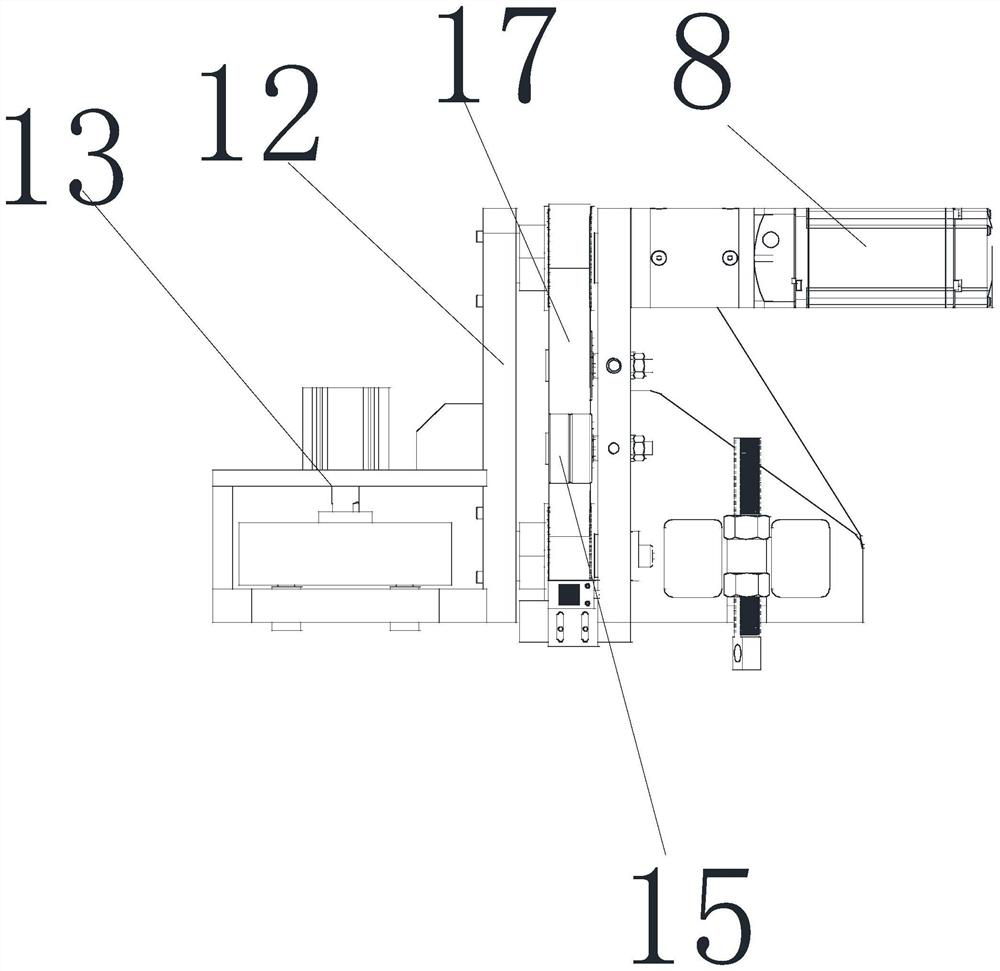

[0030] The feeding mechanism of the automatic anaerobic glue injection machine includes the glue injection machine body 1, the glue injection machine body 1 includes the feeding component 3, the feeding area 6 and the feeding unit 2, the feeding unit 2 includes the installation Seat 9, driver 8, swing rod 11 and self-adjusting grabbing mechanism, mounting seat 9 is installed on the feeding area 6, specifically side, the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com