Recycling device and method for preparing active calcium oxide as calcium carbide raw material from carbide slag

A technology of activated calcium oxide and carbide slag, applied in the direction of calcium carbide, calcium/strontium/barium oxide/hydroxide, carbide, etc., can solve the pollution of the environment by calcium carbide slag, low recycling rate of raw materials, lack of lime, etc. problems, to achieve the effect of preventing overload operation, improving production efficiency and ensuring comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

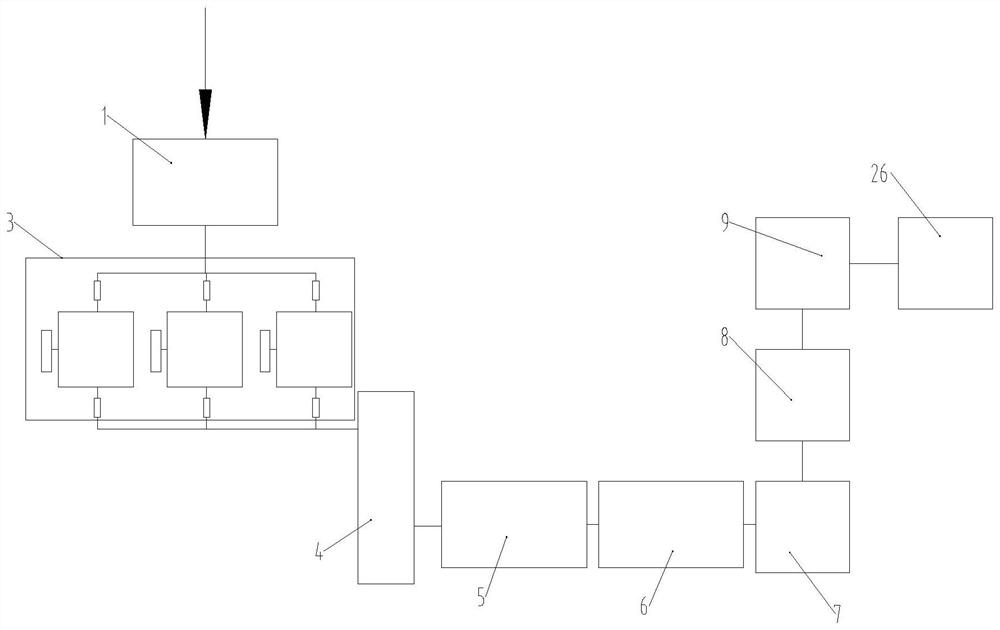

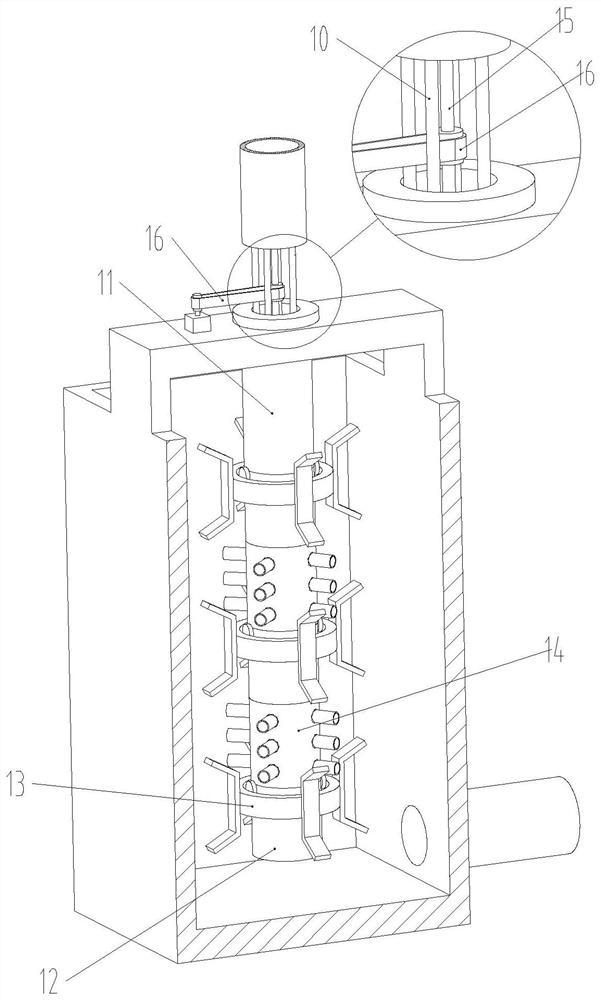

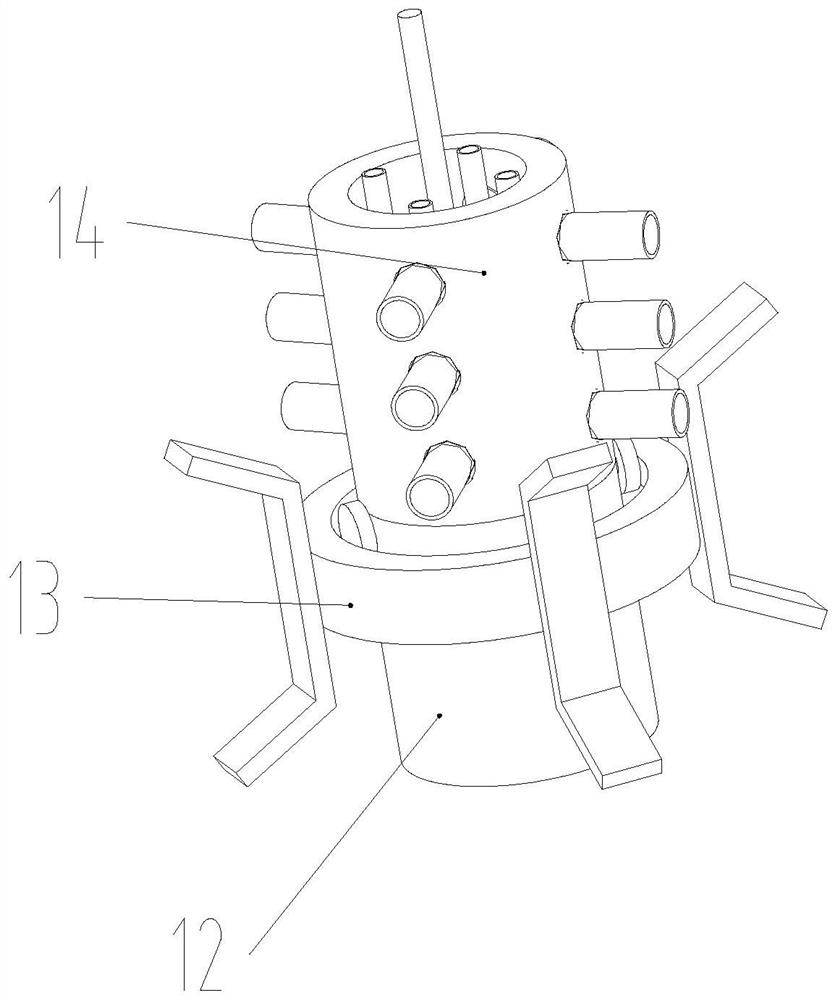

[0042] Example: as figure 1 - Figure 5As shown in the figure, a recycling device for preparing active calcium oxide calcium carbide raw materials from calcium carbide slag of the present invention includes a slurry preparation device, a hydrocyclone slag removal device, an impurity removal and refining device 6, a washing and filtering device 7, a dryer 8, a calciner 9 and The extrusion molding device 26, and the slurry preparation equipment, the hydrocyclone slag removal device, the impurity removal and refining equipment 6, the washing and filtering device 7, the dryer 8, the calcining furnace 9 and the extrusion molding device 26 are connected in sequence. The slurry preparation equipment It includes a slurry preparation tank 1 and a brown stock storage tank 3. The output end of the slurry preparation tank 1 is fixedly connected to the three brown stock storage tanks 3 through three feeding branch pipes, respectively. The three brown stock storage tanks 3 The three discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com