Spherical graphite turbine classifier

A technology of turbo classifier and spherical graphite, which is applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. It can solve the problems of affecting the separation efficiency of classifying wheels and coarse materials are easy to get stuck.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

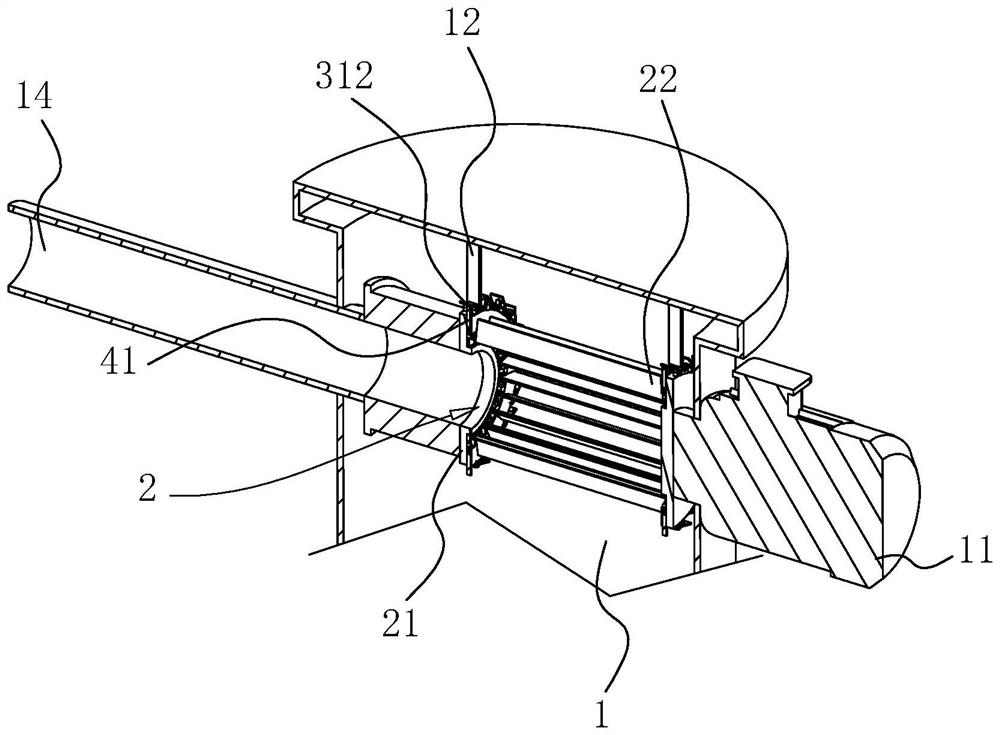

[0037] The following is attached Figure 1-9 The application is described in further detail.

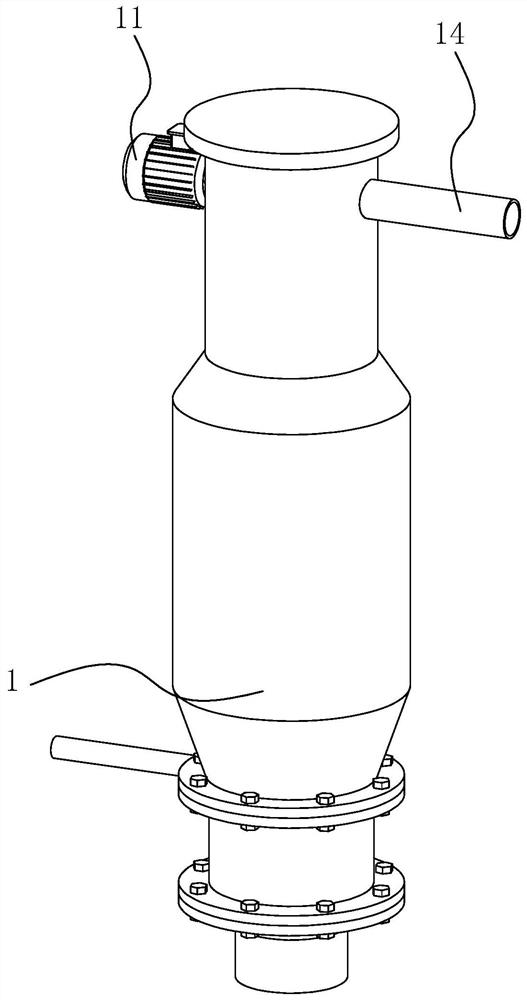

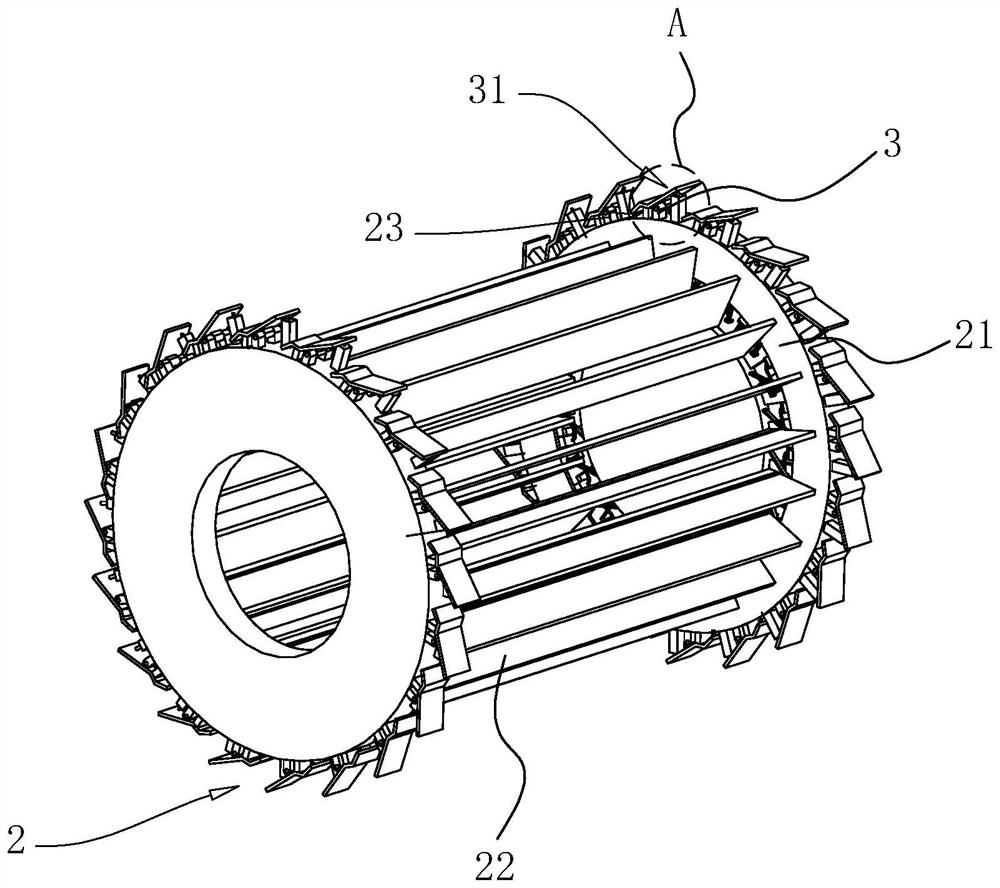

[0038] The embodiment of the present application discloses a spherical graphite turbine classifier. refer to figure 1 with figure 2, a spherical graphite turbine classifier includes a classifier cylinder 1, the bottom of the classifier cylinder 1 is arranged in a funnel shape, the inner wall of the classifier cylinder 1 is rotated and connected with a classifier wheel 2 near the top, and the outer wall of the classifier cylinder 1 corresponds to The position of the classifying wheel 2 is fixedly connected with a driving motor 11. The classifying wheel 2 includes two flanges 21 and a plurality of blades 22. The output shaft of the driving motor 11 is fixedly connected to the flange 21, and the blades 22 are arranged on the two flanges. Between the disks 21 , both ends of the blades 22 are respectively fixedly connected to two flanges 21 , and there is a feeding gap between adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com