Glass fiber reinforced plastic sandwich laminated board production equipment

A technology for production equipment and sandwich layers, applied in the field of glass fiber reinforced plastic sandwich laminate production equipment, can solve problems such as poor fit and affect the quality of finished products, and achieve the effect of ensuring the quality of finished products and avoiding springback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

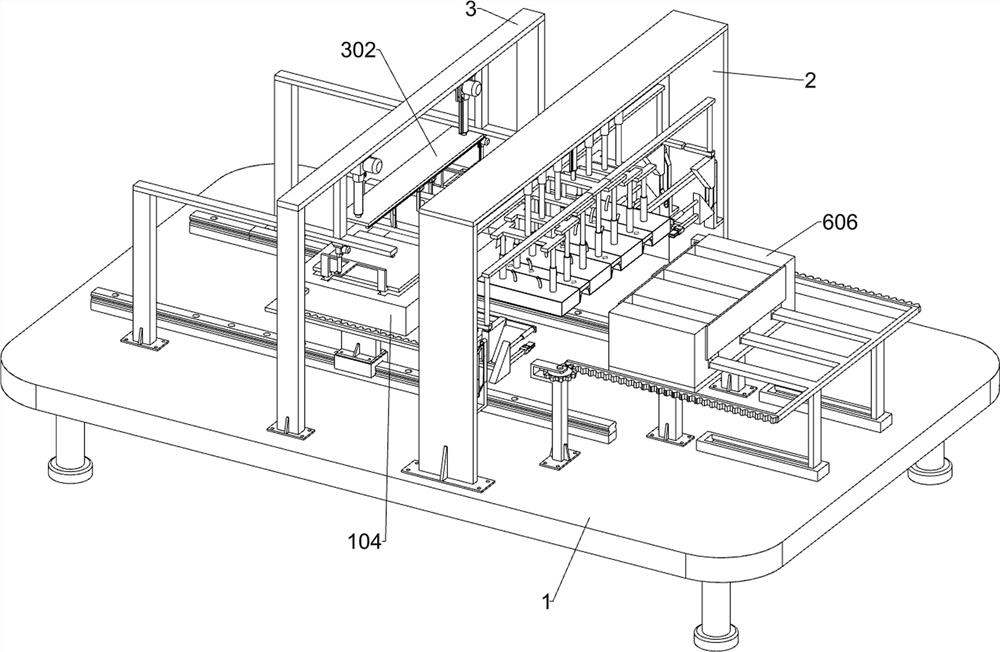

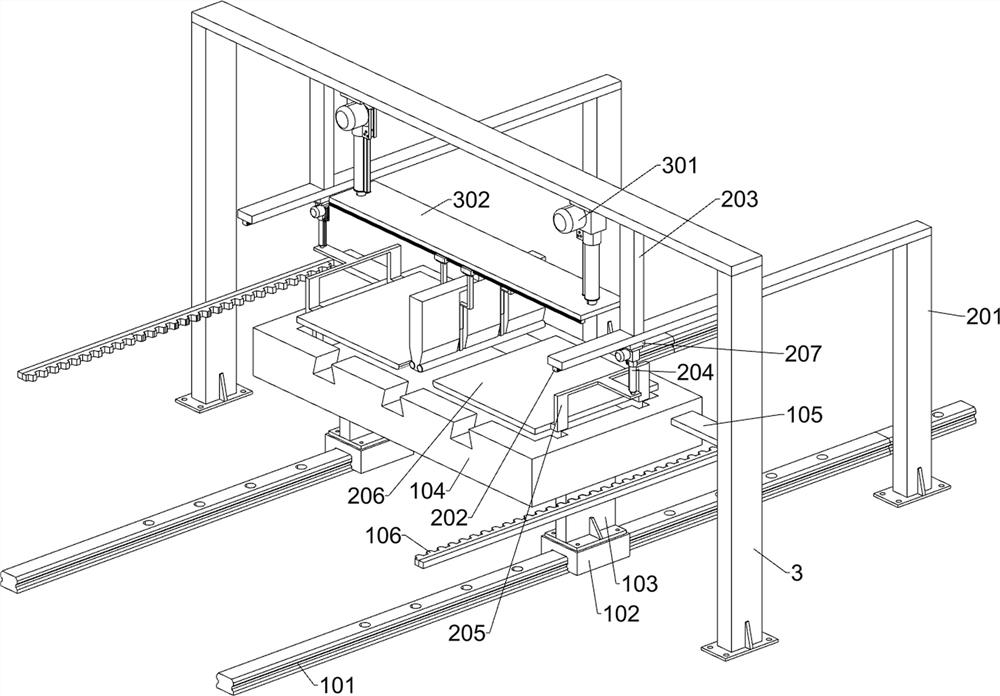

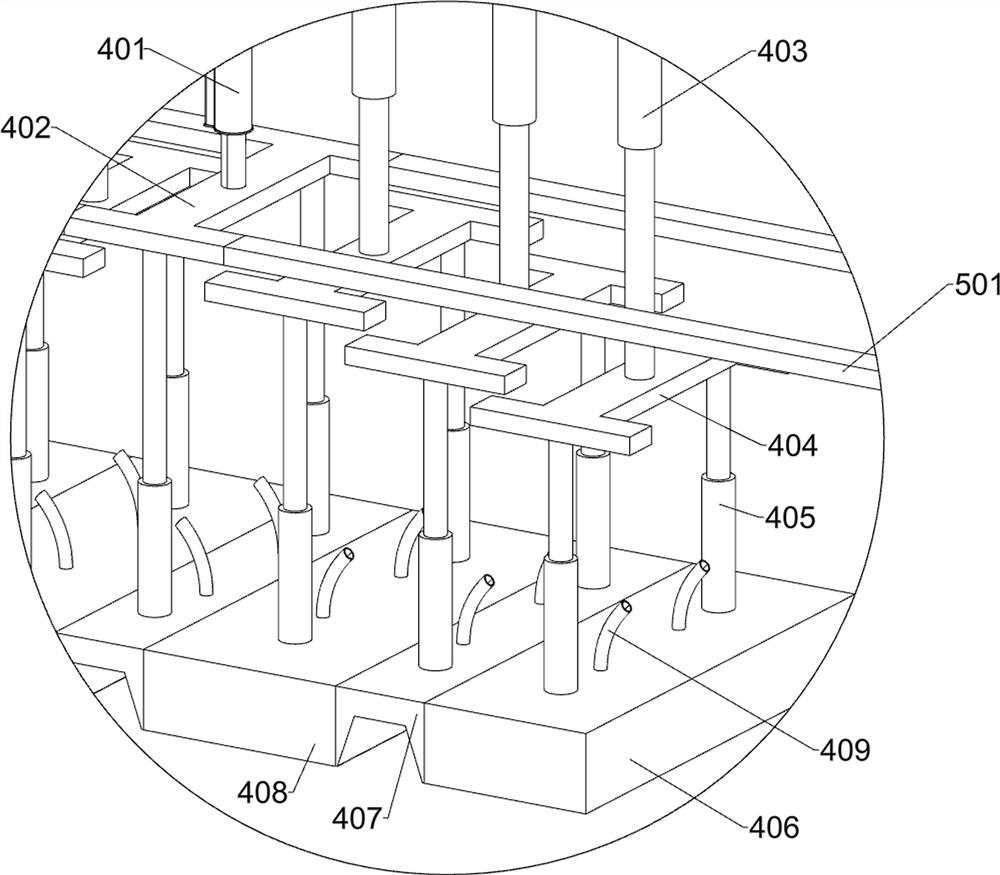

[0029] A kind of FRP sandwich laminate 305 production equipment, such as Figure 1-10 As shown, it includes a bottom frame 1, a mounting frame 2, a first fixing frame 3, a conveying assembly, a placing assembly, a flattening assembly, a pressing assembly and a clamping assembly; The first fixed frame 3; the mounting frame 2 is located on the left side of the first fixed frame 3; the upper side of the bottom frame 1 is equipped with a conveying assembly; the upper right part of the bottom frame 1 is equipped with a placement assembly; The middle part of the first fixed frame 3 is equipped with a pressing assembly; the upper part of the mounting frame 2 is equipped with a pressing assembly; the pressing assembly is located on the left side of the pressing assembly; Component connections.

[0030] Among them, the conveying assembly includes a first electric guide rail 101, a first electric slider 102, a first support plate 103, a lower mold 104, a second L-shaped plate 105, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com