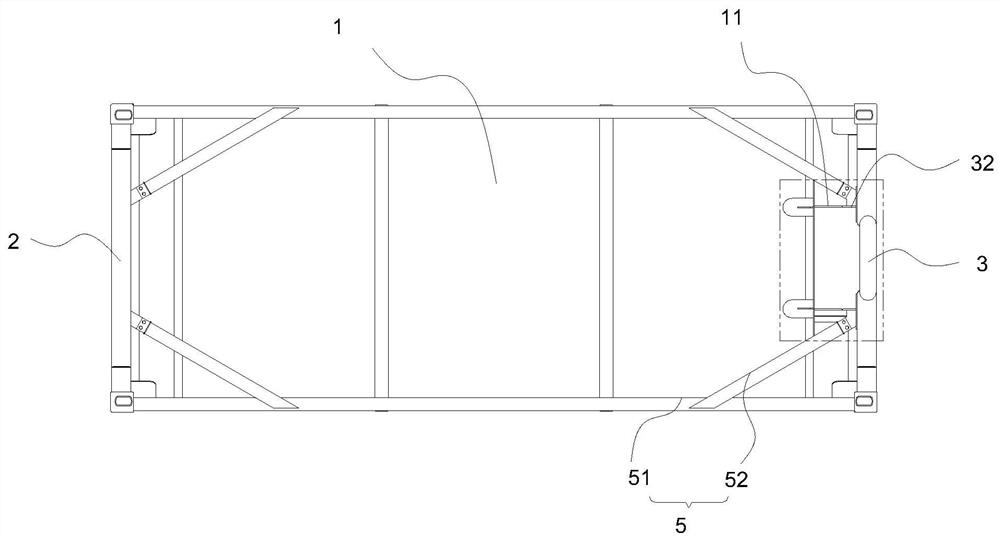

Tank container

A tank container and tank body technology, which is applied in the field of tank container manufacturing, can solve problems such as low production efficiency and long painting hours, and achieve the effects of improving production efficiency, reducing labor intensity, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

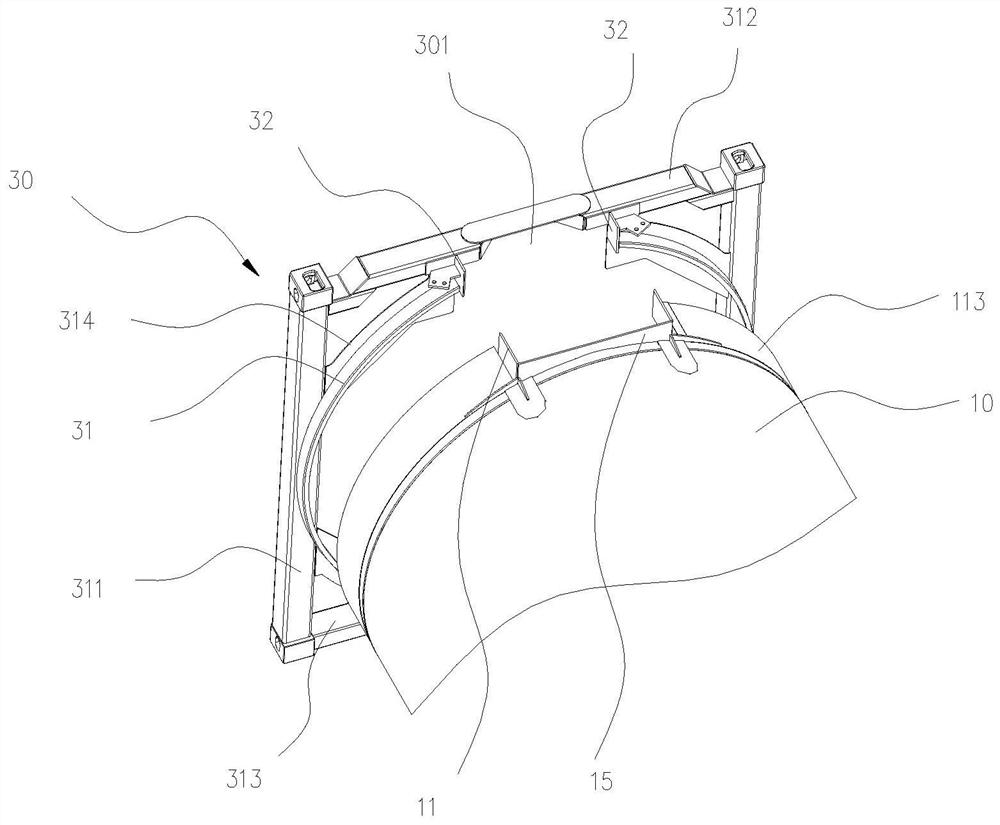

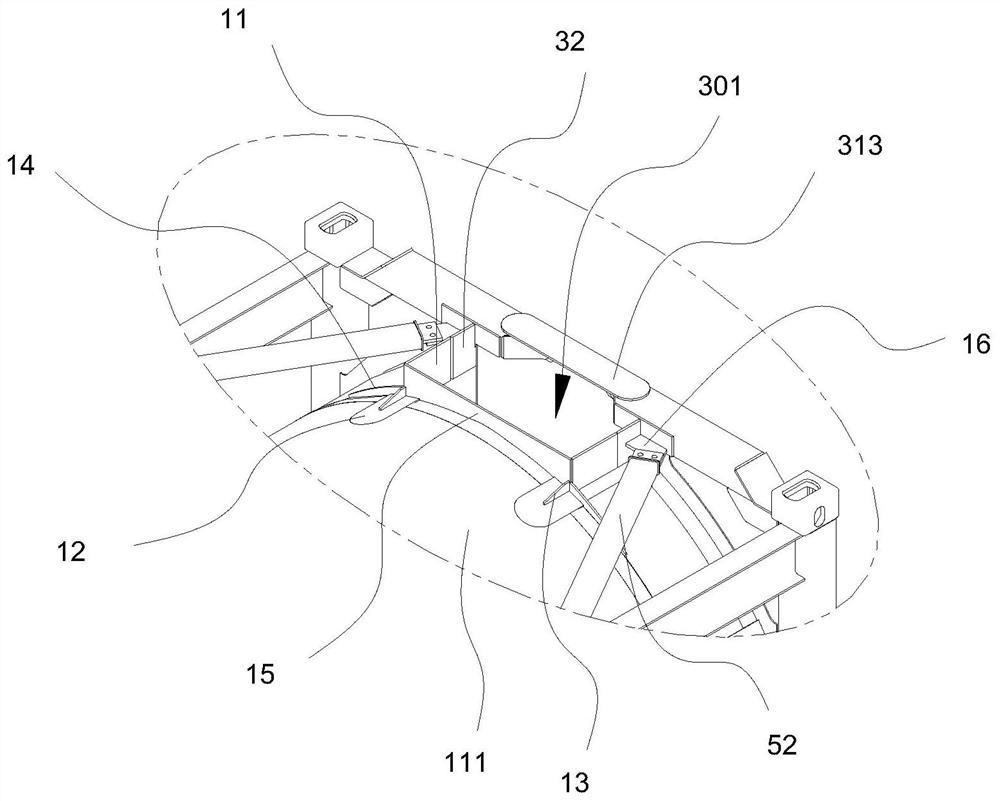

[0034] In the related art, the bottom of the rear end of the tank body has a discharge port, and a bottom valve is arranged at the discharge port. In order to provide enough operating space at the discharge port, the bottom beam of the rear end frame of the tank body near the discharge port needs to be broken into two sections, and connected by a bottom plate to form a U-shaped gap, which can prevent The bottom valve interferes with the end lower beam. Due to the existence of the gap, it is necessary to set a rear bottom reinforcement component on the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com