Facing wallboard keel mounting system

A technology of decorative panels and wall panels, applied in covering/lining, construction, building construction, etc., can solve problems such as large environmental pollution, difficult leveling of wall panels, and long construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

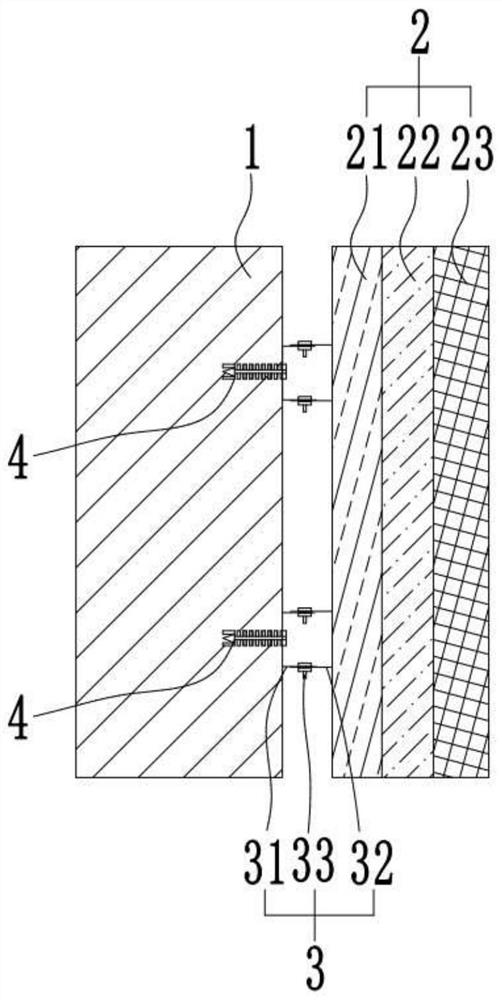

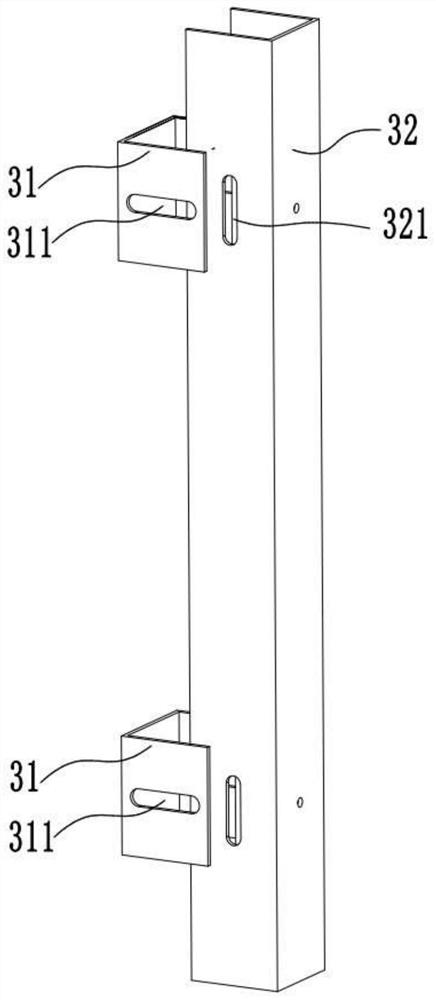

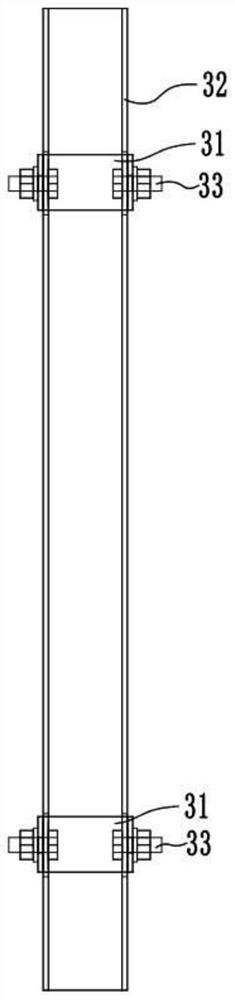

[0027] Such as Figure 1 to Figure 5 In this embodiment shown, a decorative wall panel keel installation system includes a structural base 1 and a wall panel layer 2, and the wall panel layer 2 includes a keel board 21, a wooden base plate 22 and a decorative panel 23 in sequence from the inside to the outside. The inner side of the keel board 21 is connected with the outer side of the structural base 1 by an azimuth adjustment mechanism 3, the outer side of the keel board 21 is connected with the inner side of the wood base 22, and the outer side of the wood base 22 Connected with the inner side of the veneer 23, the keel board 21 can be rotated or moved relative to the structural base 1 through the azimuth adjustment mechanism 3, and the flatness and verticality of the keel board 21 can be adjusted. The outer side of the keel board 21 and the wood The inner side of the base plate 22 is connected, and the outer side of the wooden base plate 22 is connected with the inner side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com