Hot riveting technique in use for piston rod

A technology of piston rod and hot riveting, applied in the direction of piston, cylindrical piston, plunger, etc., can solve the problems of high cost of precision steel pipe, many processes, difficulty in ensuring accuracy, etc., to reduce production cost, good connectivity, and reduce processing. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

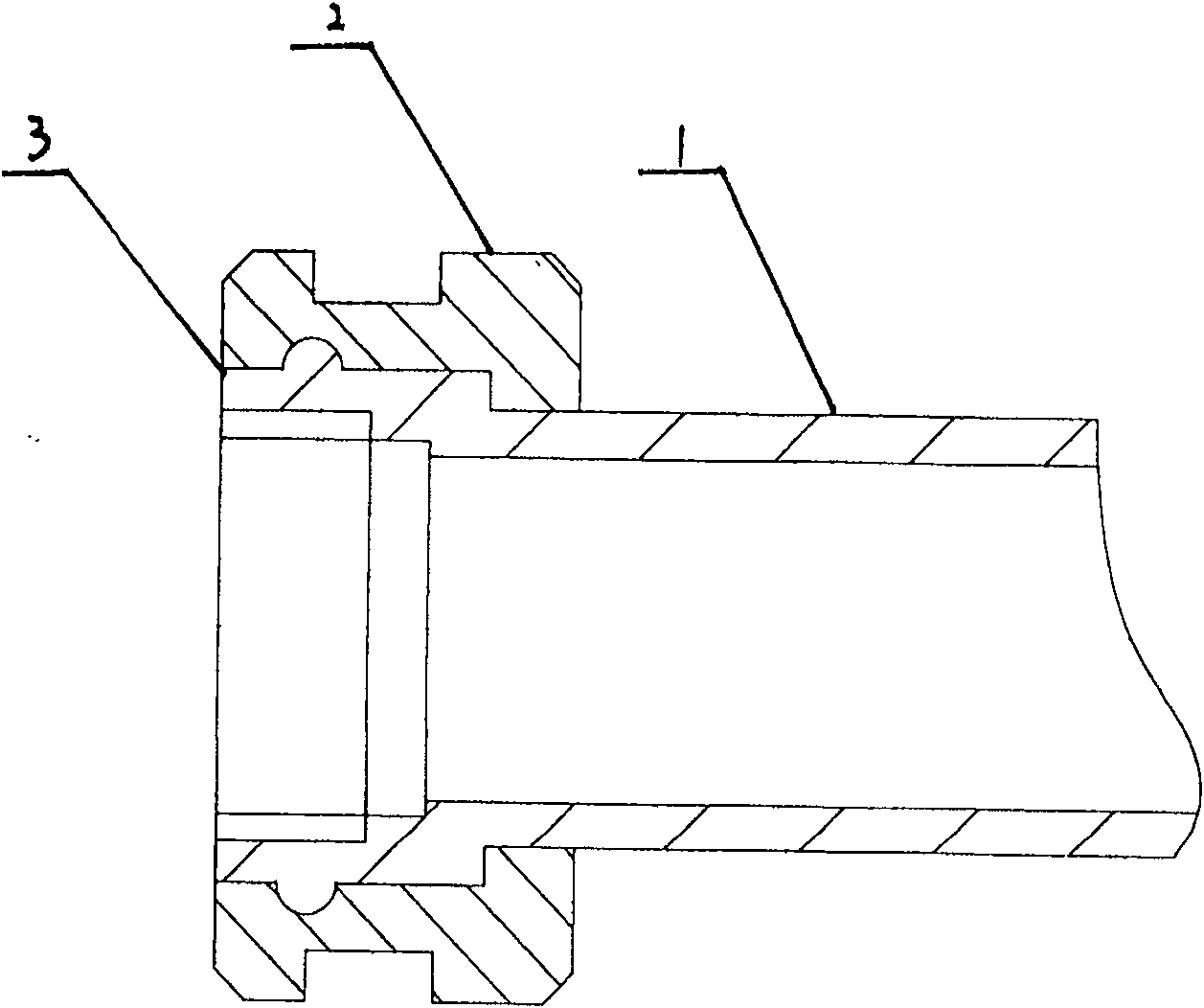

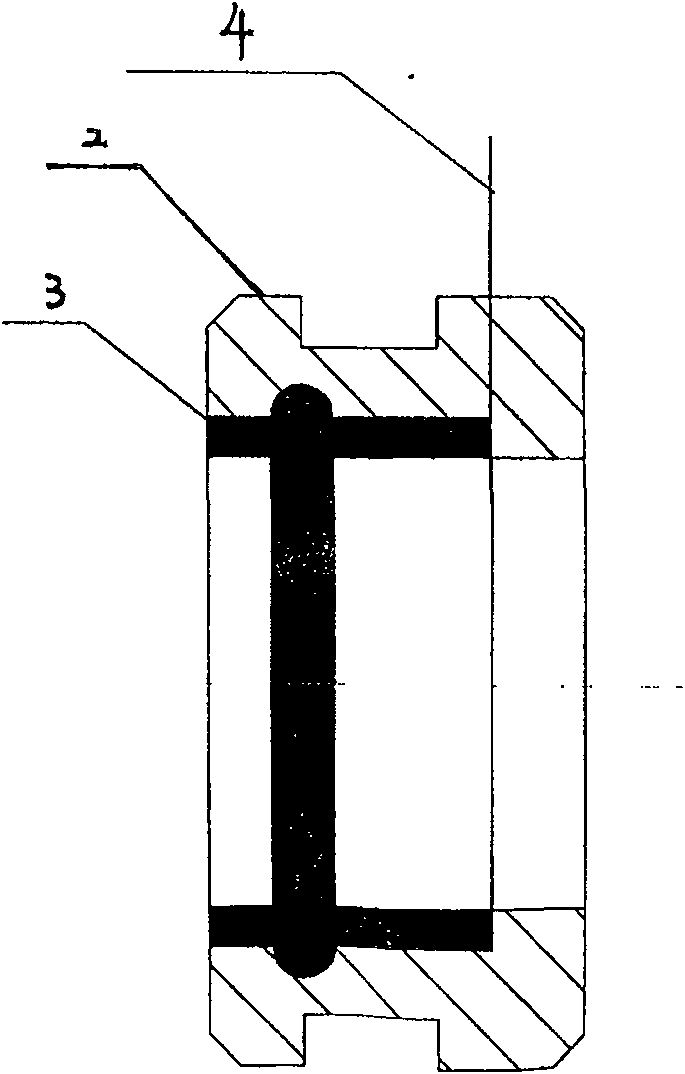

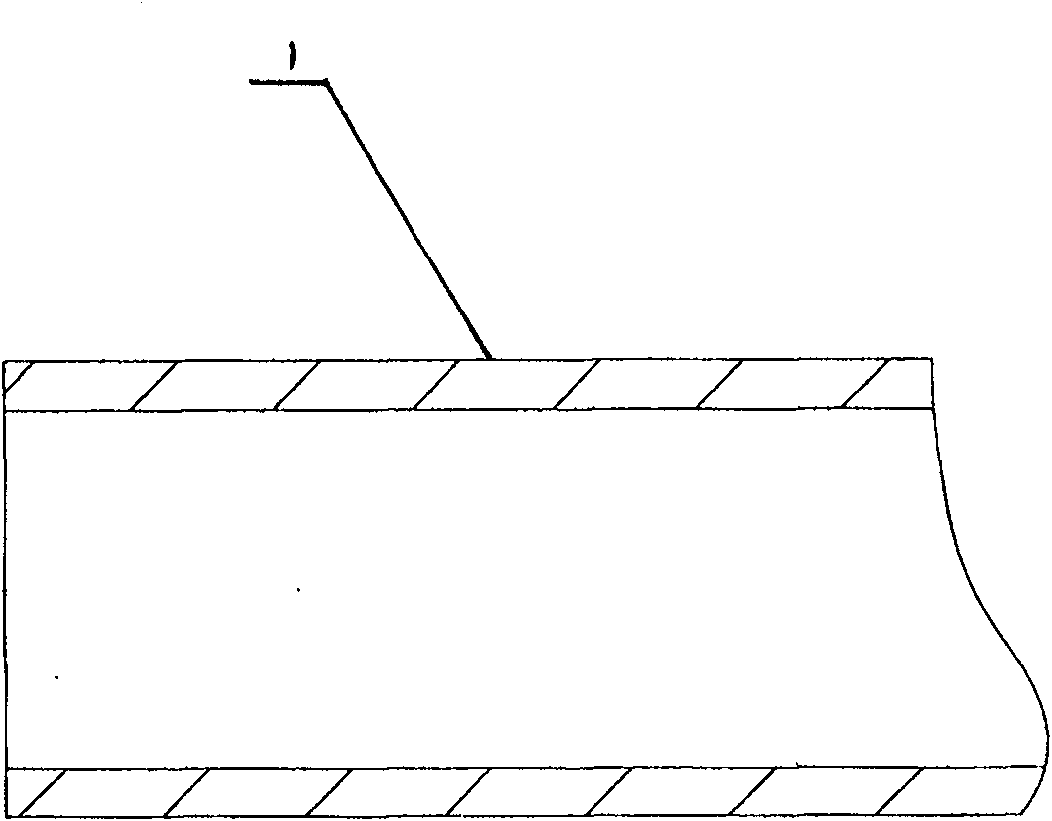

[0010] according to figure 1 , figure 2 and image 3 Among them, the present invention discloses a hot riveting process for piston rods, which includes the following steps: step 1, first cutting the rod body 1 of the piston rod according to the required length; step 2, cutting the inner diameter of the rod body 1 after cutting Use a drill bit to ream the hole; step 3, shrink the diameter of the head of rod body 1 in step 2, which can reduce the diameter of the head; step 4, shrink the other head of rod body 1 and the piston in step 3 Put the head 2 into the induction furnace and heat it to 400°C-500°C; step 5, fill the cavity 3 inside the piston head 2, insert the rod body 1 heated in step 4 into the heated piston head 2 Insert the piston head 2 into the slot, and then punch the piston head 2. After stamping, squeeze the excess metal on the rod body 1 into the filling cavity 3 with the reference plane 4 positioned, and squeeze the filling cavity 3 tightly. After cooling, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com