Crankcase fault detection method and device and related equipment

A fault detection and crankcase technology, applied in the field of vehicles, can solve the problems that it is difficult to determine the disconnection of the crankcase pipeline and affect the accuracy of crankcase fault detection, and achieve the effect of improving the accuracy of fault detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

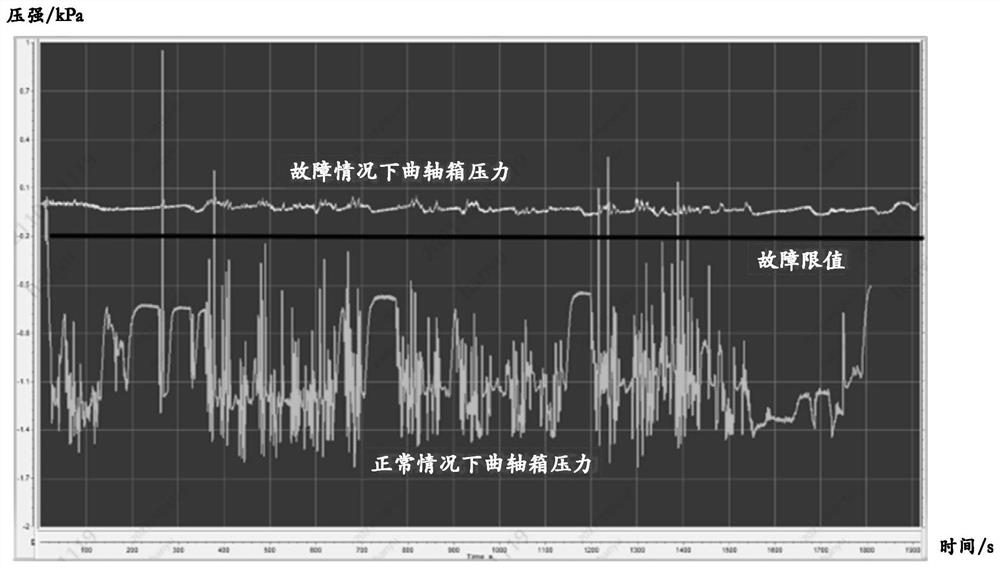

[0048]At present, when detecting the fault of the crankcase, the pressure value of the crankcase is usually measured by the pressure sensor installed before and after the oil-gas separator. If the crankcase is not faulty, the pressure value of the crankcase measured by the pressure sensor is usually between -1kPa and -0.3kPa, which is not greater than the preset fault limit, such as -0.2kPa (relative to the atmospheric pressure ), at this time, it is determined that the crankcase is not faulty. However, if the pipeline of the crankcase is disconnected or leaks air, the pressure in the crankcase is basically equal to the atmospheric pressure, such as figure 1 As shown, the pressure value of the crankcase measured by the pressure sensor may be close to 0kPa. At this time, if the measured pressure value is greater than the fault limit value, it is determined that the crankcase has a fault.

[0049] However, in practical applications, due to factors such as pressure sensor drift ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com