System and method for detecting use degree of filter element of operation smoke exhauster

A detection system and fume extractor technology, which is applied in measurement devices, scientific instruments, analysis of suspensions and porous materials, etc., can solve problems such as waste of resources, scrapped filter elements, and environmental pollution, and achieve the effect of preventing waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

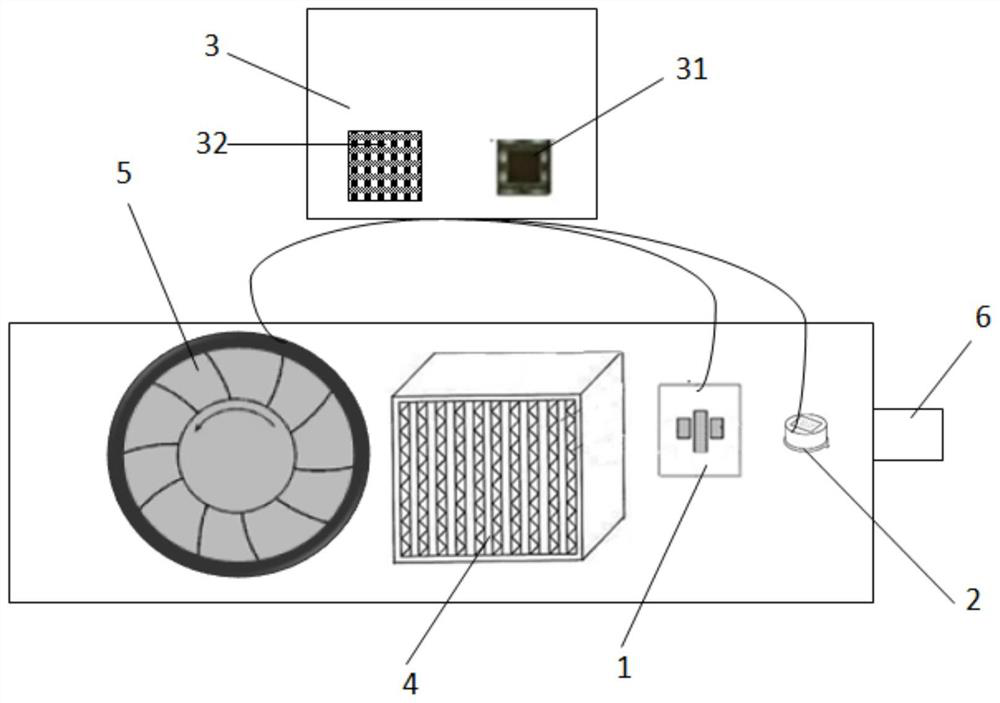

[0043] Such as figure 2 As shown, in an embodiment of the detection system for detecting the use degree of the surgical smoke exhaust filter element of the present invention, the flow detection unit 1 and the smoke sensor 2 can be arranged between the filter element 4 and the inlet end 6 of the smoke exhaust channel, and in the exhaust The outlet end in the smoke passage is also provided with a negative pressure pump 5, which can also be a fan, and the negative pressure pump 5 is electrically connected with the main control unit 3, and the main control unit 3 can control the suction power of the negative pressure pump 5. This arrangement is mainly based on the difference between the current gas flow rate and the gas flow rate at the inlet port 6 when the new filter element is just used under the same suction power of the negative pressure pump 5, to realize the effective state of the filter element 4. Judging, for example, the suction power of the negative pressure pump 5 can...

Embodiment 2

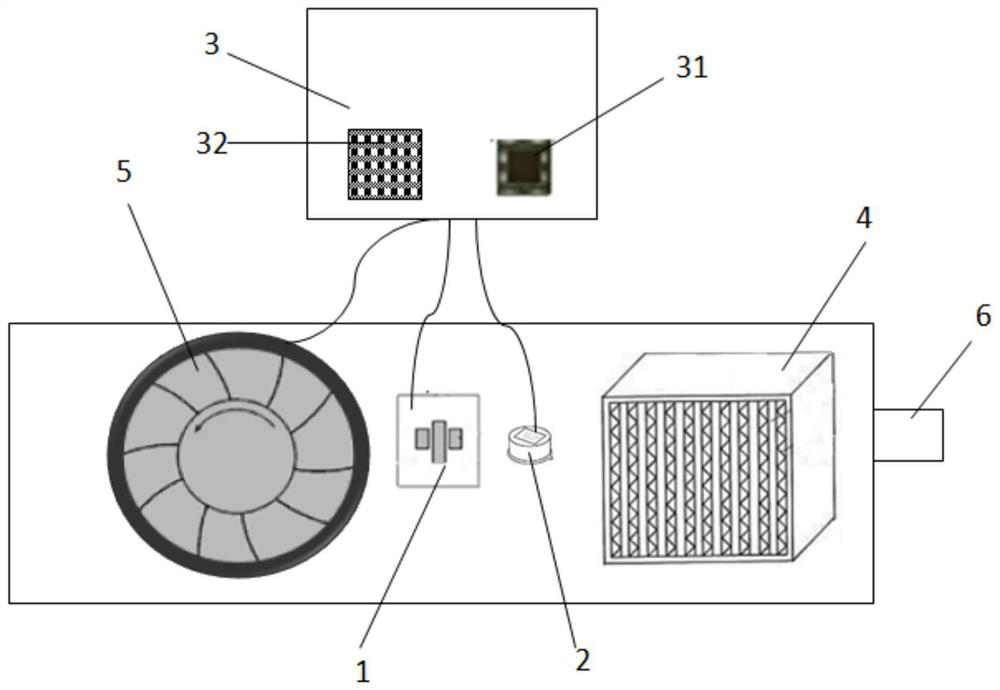

[0045] Such as figure 1 As shown, in an embodiment of the detection system for detecting the use degree of the filter element of the surgical smoke exhauster of the present invention, the flow detection unit 1 and the smoke sensor 2 can be arranged between the filter element 4 and the outlet end of the smoke exhaust channel, and in the smoke exhaust The outlet end in the channel is also provided with a negative pressure pump 5, which can also be a fan, of course. The negative pressure pump 5 is electrically connected to the main control unit 3, and the main control unit 3 can control the suction power of the negative pressure pump 5. This arrangement mainly By comparing the difference between the current gas flow rate and the gas flow rate at the outlet end of the new filter element at the beginning of use under the same power of the negative pressure pump 5, the effective state of the filter element 4 can be judged, for example, in negative pressure The suction power of the p...

Embodiment 3

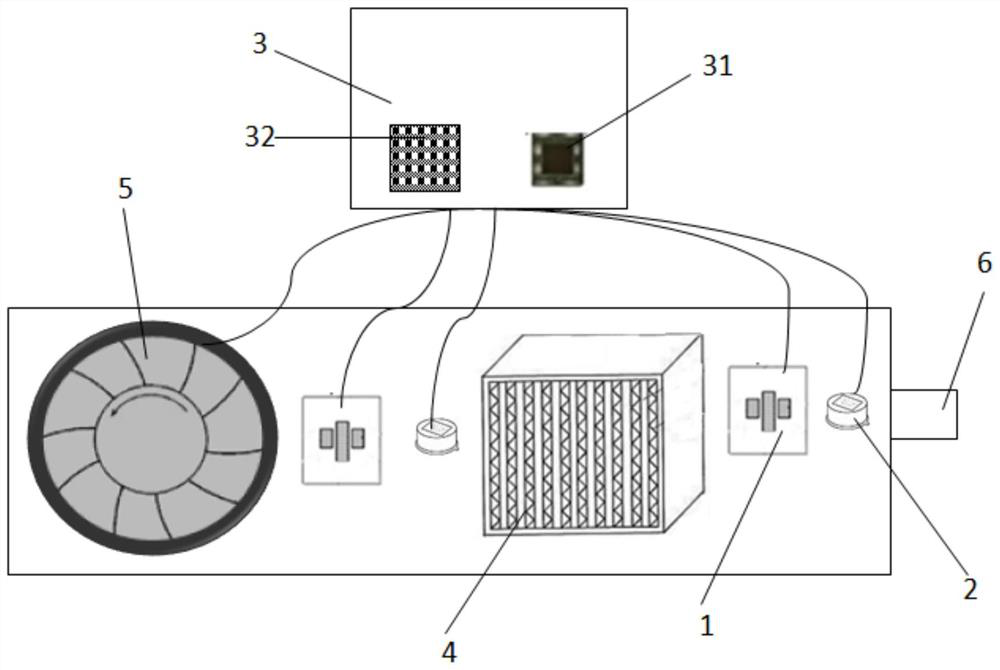

[0047] It can be understood that the above-mentioned embodiment is not direct enough to obtain part of the detection data, which will make the detection process more complicated, and will introduce errors in the corresponding conversion process. Therefore, as image 3 As shown, in an embodiment of the detection system for the use degree of the surgical smoke exhaust filter element of the present invention, the flow detection unit 1 and the smoke sensor 2 can preferably be set to two, and one flow detection unit 1 and one smoke sensor 2 are One measuring unit, two measuring units are respectively arranged between the filter element 4 and the inlet end 6 of the smoke exhaust channel and between the filter element 4 and the outlet end of the smoke exhaust channel, and are arranged between the filter element 4 and the inlet end 6 of the smoke exhaust channel The flow detection unit 1 and the smoke sensor 2 can be used to measure the gas flow and smoke amount of the gas without smok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com