BLDCM current distribution method based on Hall rotation vector QPLL

A technology of rotation vector and current distribution, applied in vector control systems, electrical components, control generators, etc., can solve the problems of limited ability to suppress commutation torque fluctuations, increase control costs and computational complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

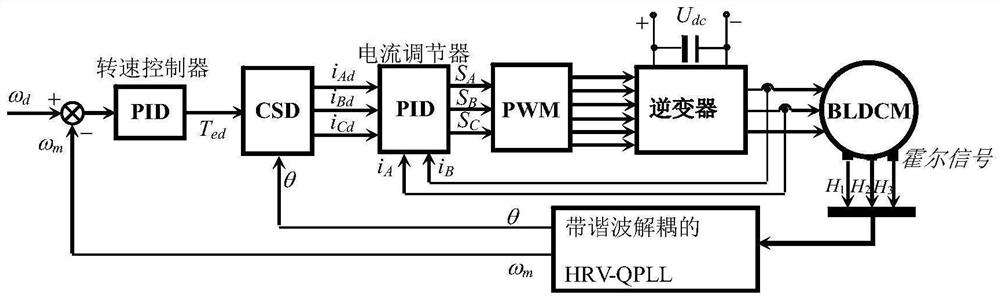

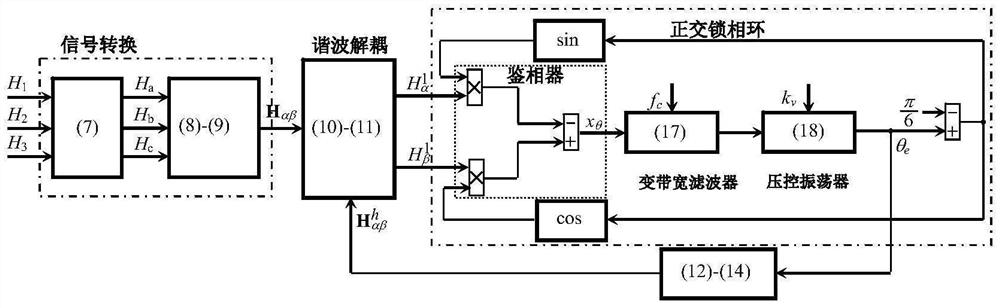

[0028] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0029] First, the desired phase current i is derived from the BLDCM mathematical model d and electromagnetic torque T e the size of. See the following five formulas for the calculation process. The BLDCM voltage equation is:

[0030] u xg = Ri x +L(di x / dt)+e x + u ng (x=A,B,C) (7)

[0031] where u xg , u ng 、e x and i x They are phase voltage, neutral point voltage, opposite electromotive force and phase current respectively. The formula for calculating the total electromagnetic power of BLDCM is:

[0032] P e = e A i A +e B i B +e C i C (8)

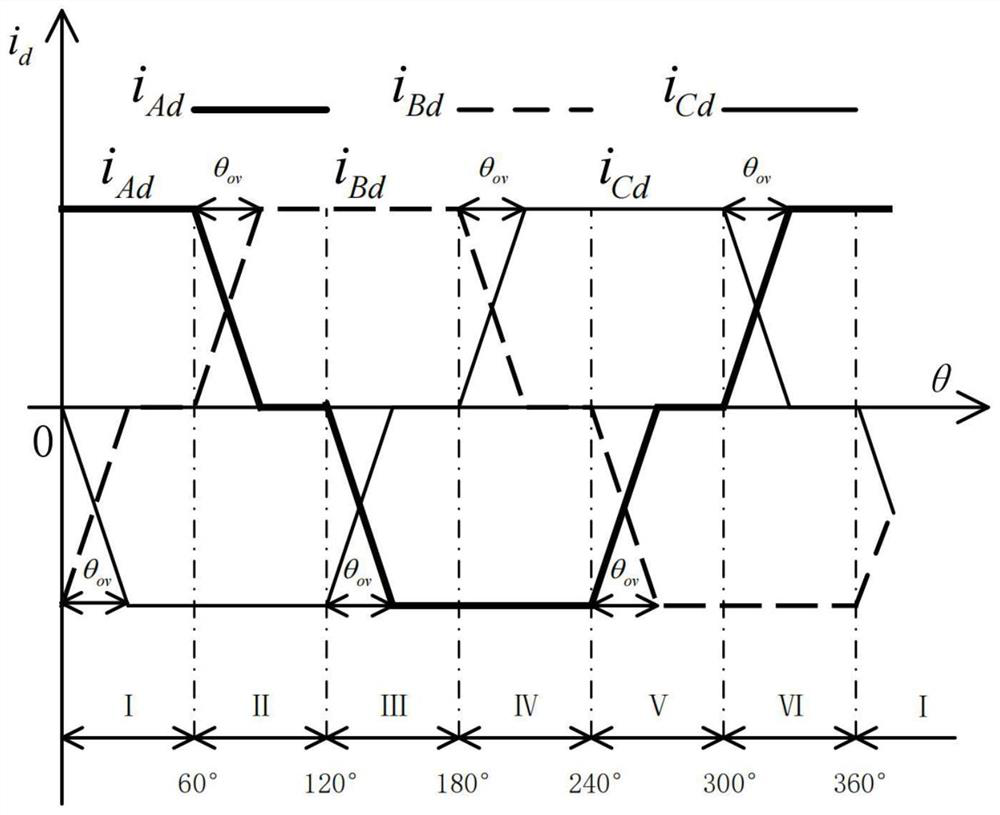

[0033] From Figure 4 In the ideal phase current and the opposite electromotive force, the total instantaneous power available is:

[0034] P e = 2e x i x (x=A,B,C) (9)

[0035] The calculation formula of electromagnetic torque is:

[0036]

[0037] In the formula, ω m is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com