Tympanic membrane repair stent material, preparation method and preparation method of tympanic membrane repair stent

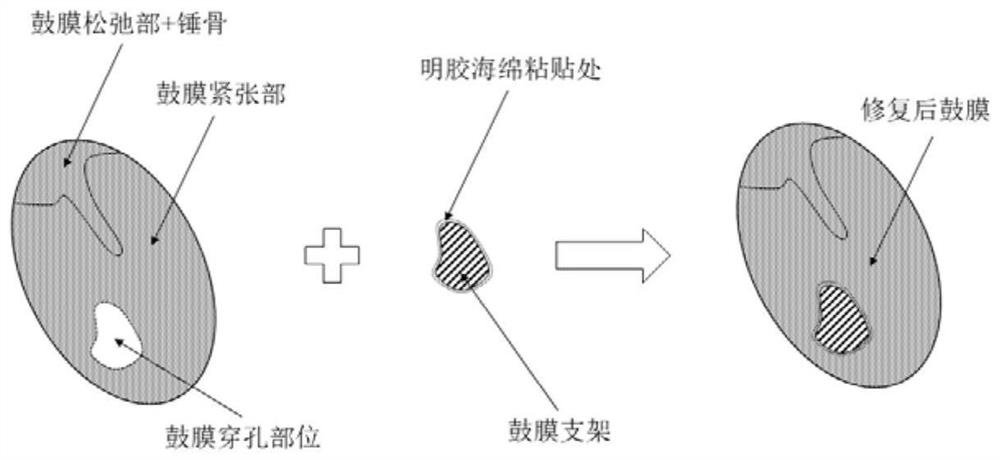

A stent material and tympanic membrane technology, applied in the field of materials, can solve the problems such as the large difference between the acoustic properties and the mechanical properties of the natural tympanic membrane structure, the inability to achieve the tympanic membrane vibration properties, and the easy failure of surgical treatment, so as to achieve individualized parameter regulation and convenience. Effects of cell attachment growth, excellent deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] In the second aspect, the present invention provides a method for preparing the tympanic membrane repair stent material described in the first aspect above, the method comprising: using electrostatic fusion direct writing technology to melt biodegradable materials, stacking and spinning to form uniform pores, And layered fiber webs stacked between layers.

[0047] Wherein, the biodegradable material is any one of polylactic acid, lactic acid / glycolic acid copolymer and polycaprolactone;

[0048] The pores are regular polygons.

[0049] During specific implementation, the preparation method of the tympanic membrane repair stent material provided by the present invention effectively improves the uniformity of repeated stacking of fiber filaments between layers during the spinning process by applying the electrostatic fusion direct writing technology to the preparation of the tympanic membrane repair stent material. The pore shape and size of the layered fiber net stacked...

Embodiment 1

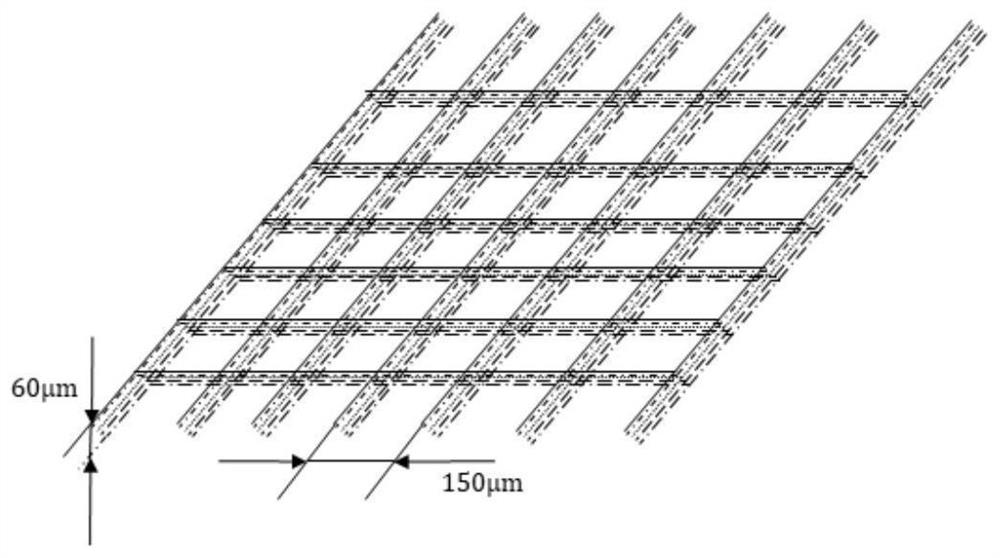

[0058] Using a bioscaffold printer with an electromelt spinning module, a virtual specific shape is first drawn on the print bed by computer software, such as figure 1 shown. preparation figure 1 In the structural form, the high molecular polymer is placed in the collection barrel, and the high molecular polymer is turned into a molten state by heating. The diameter of the nozzle of the collection barrel is 250 microns, the distance from the nozzle to the printing bed is 2.5mm, and a voltage of 8.15kv is applied Prepare 15-micron fibers, form a stable low-velocity molten jet by applying a voltage between the nozzle and the print bed, and directly print the molten polymer on the print bed, which is formed by sequential and consistent stack printing figure 1 The interlayer (4 layers) stacked layered web structure is shown.

[0059] The mechanical properties of the prepared layer (4-layer) fiber web were tested by DMA dynamic mechanics experiment, uniaxial tensile experiment an...

Embodiment 2

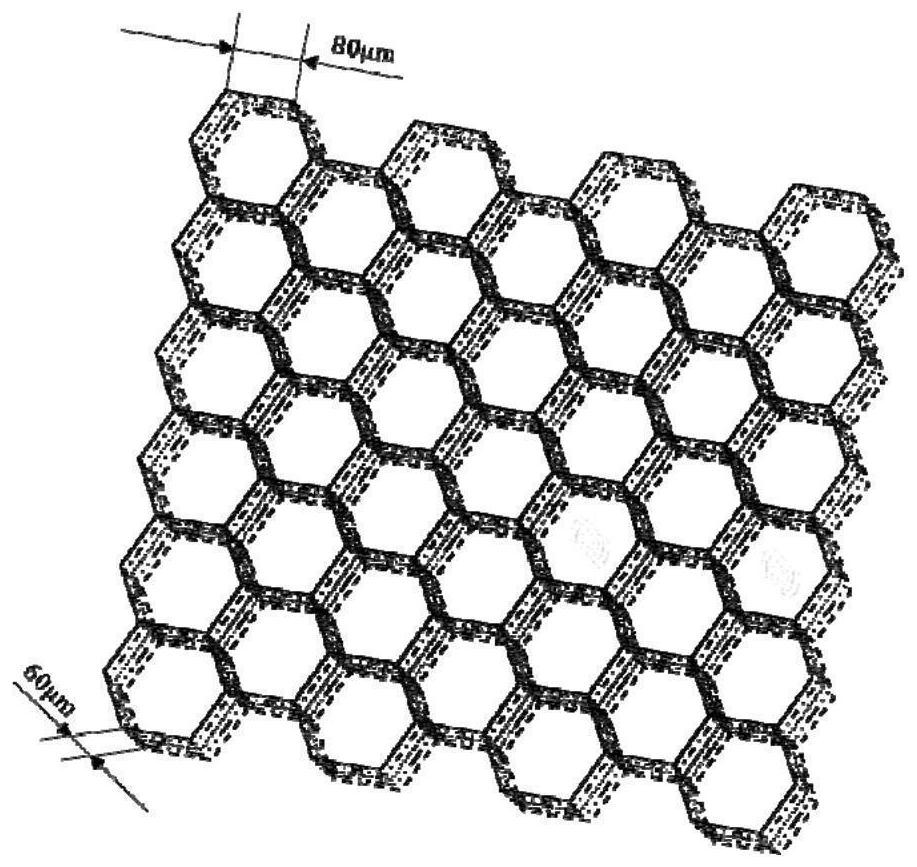

[0063] Using a bioscaffold printer with an electromelt spinning module, first draw on the print bed by computer software such as figure 2 As shown in the dummy specific shape, the preparation figure 2 In the structural form, the high molecular polymer is placed in the collection barrel, and the high molecular polymer is turned into a molten state by heating. The diameter of the nozzle of the collection barrel is 250 microns, the distance from the nozzle to the printing bed is 2.5mm, and a voltage of 8.15kv is applied Prepare 20-micron fibers, form a stable low-velocity molten jet by applying a voltage between the nozzle and the print bed, and directly print the molten polymer on the print bed, which is formed by sequential and consistent stack printing figure 2 The interlayer (3 layers) stacked layered web structure is shown.

[0064] The mechanical properties of the prepared layer (4-layer) fiber web were tested by DMA dynamic mechanics experiment, uniaxial tensile experi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com