Intelligent vegetable cutting equipment

An intelligent and equipment technology, applied in the direction of metal processing, etc., can solve the problems that affect the cutting effect, the processing method is not very intelligent, etc., and achieve the effect of concentrated and fast unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

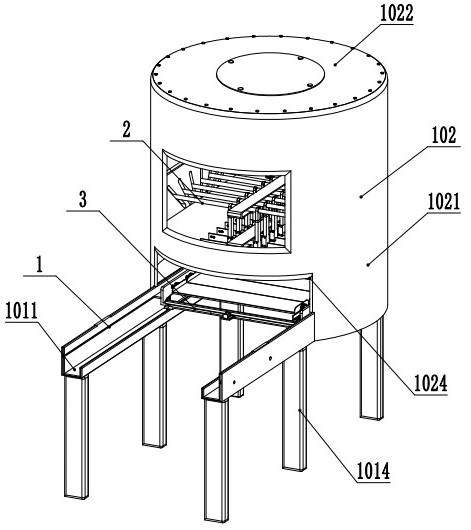

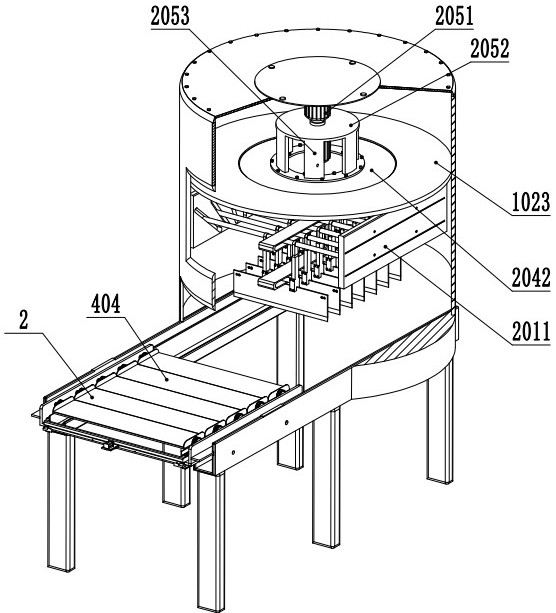

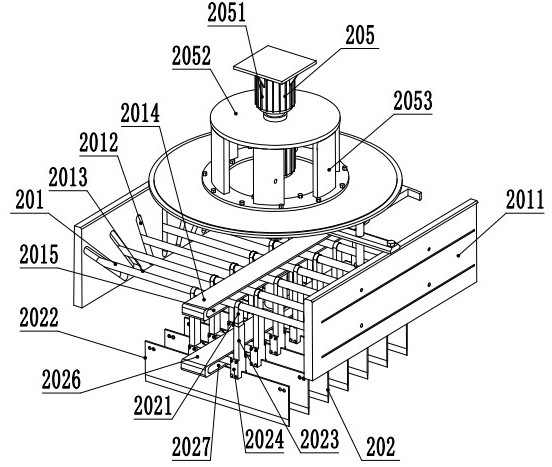

[0041] The intelligent vegetable cutting equipment provided by the present invention is mainly used for cutting materials, especially some tuber-shaped materials with a certain length, or cutting vegetables into sections or blocks to form strips or segmented materials. . like figure 1 As shown, the cutting equipment mainly includes a frame 1 and a cutting mechanism 2 and a feeding mechanism 3 arranged on the frame 1 . The conveying mechanism 3 is used to carry and convey the materials to be cut, and the cutting mechanism 2 is used to cut the materials conveyed by the conveying mechanism 3 .

[0042] The cutting mechanism 2 is arranged on one side of the frame 1, and the cutting mechanism 2 is located above the feeding mechanism 3 in the vertical direction. The material conveying mechanism 3 includes a material loading assembly and a horizontal traversing assembly, and the horizontal traversing assembly can drive the loading assembly to reciprocate along the length direction ...

no. 2 example

[0076] This embodiment differs from the first embodiment in that: Figure 12 and 13 As shown, a material swing mechanism 6 is provided on the side of the horizontal frame 101 away from the cutting mechanism 2, and the material swing mechanism 6 is used to transport materials to the conveying mechanism 3 in an orderly manner to realize orderly distribution of materials. When in use, the material is put into the swing mechanism 6 through the conveying device or manually, and the material is distributed to the conveying mechanism through the swing mechanism 6 .

[0077] The two horizontal frames 101 are respectively fixedly connected with a column 601, and a screw slide module 602 is fixedly connected between the two columns 601. The screw slide module 602 is a prior art, and will not be described in detail in this application. . The swing mechanism 6 includes a swing hopper 603, the top of the swing hopper 603 is fixedly connected with a swing bar 604, the swing bar 604 is fix...

no. 3 example

[0083] This embodiment is based on the second embodiment, such as Figure 14 As shown, a waste screen basket 7 and a finished product basket 8 are added, the waste screen basket 7 and the finished product basket 8 are placed on the ground or other platforms, and the waste screen basket 7 is located inside the frame 1 and vertically Just below the cutting mechanism 2, so that after the material is cut, the turning plate 404 of the loading assembly is turned over so that the cut material can just fall into the waste screen basket 7.

[0084] The waste sieve basket 7 includes a waste basket 702, the upper end surface of the waste basket 702 is inclined and is detachably connected with a screen 701, the screen 701 is configured as a variety of different apertures, and the screen 701 is used for screening corner waste, The screen 701 is also arranged obliquely, and the lower end side of the screen 701 is arranged close to the end side of the frame 1 . The finished product basket 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com