A single-sided film-coated board conveying system for circuit board production and its production process

A conveying system and film-coated board technology, applied in conveyors, conveyor objects, manufacturing tools, etc., can solve problems such as high purchase cost, circuit board damage, and complex circuit board production processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

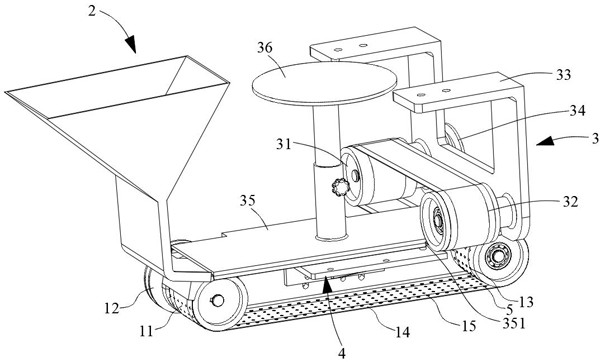

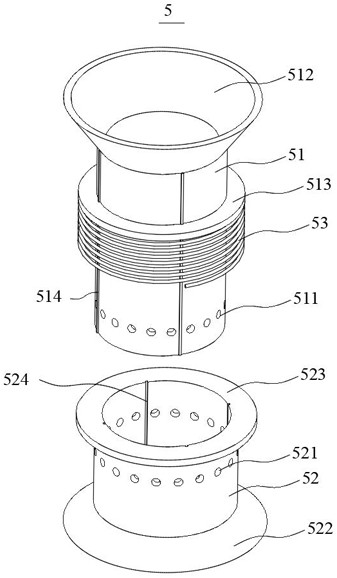

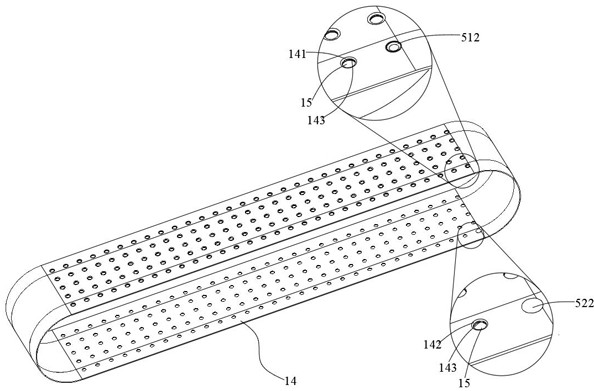

[0029] like Figure 1 to Figure 6As shown, this embodiment provides a single-sided film-coated board conveying system for circuit board production, including: two conveying rollers 11, and one of the conveying rollers 11 can be rotated, and specifically, one of the conveying rollers 11 is coaxial on one of the conveying rollers 11 A conveying drive wheel 12 is provided. The conveying drive wheel 12 is connected with a conveying motor through a belt, and the conveying drive wheel 12 is driven to rotate by the conveying motor to drive the conveying roller 11 to rotate. Pushing blocks 13 , specifically, each pushing block 13 is evenly arranged in a row along the axial direction of the conveying roller 11 , and each row of pushing blocks 13 is evenly arranged along the circumferential direction of the conveying roller 11 ; The conveyor belt 14 is rotated by the conveyor roller 11 to drive the conveyor belt 14 to rotate to realize the conveying of the workpiece, and the conveyor be...

Embodiment 2

[0051] This embodiment 2 provides a production process of a single-sided film-coated board conveying system for circuit board production, wherein fixing a single-sided film-coated board conveying system for circuit board production is the same as that of embodiment 1, and will not be repeated here.

[0052] A specific production process of a single-sided film-coated board conveying system for circuit board production is as follows: the workpieces are sequentially placed into the feeding box 21; The conveying roller 11 rotates to drive the conveying belt 14 to rotate, so that the workpiece is conveyed to the bottom of the grinding belt 32; the conveying roller 11 stops rotating; The suction film spring 53 to the lower limit ring 523 is in contact with the bottom end surface of the installation groove 143; the grinding roller 31 starts to rotate and drives the grinding belt 32 to rotate, so that the grinding belt 32 grinds the upper surface of the workpiece; the grinding debris f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com