Large-span corridor between unequal-height high-rise buildings

A technology for high-rise buildings and buildings, which is applied in the direction of building structure and construction, can solve the problems of increasing hidden safety hazards for workers, and achieve the effects of reducing hidden safety hazards, reducing workload, and smooth and accurate docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

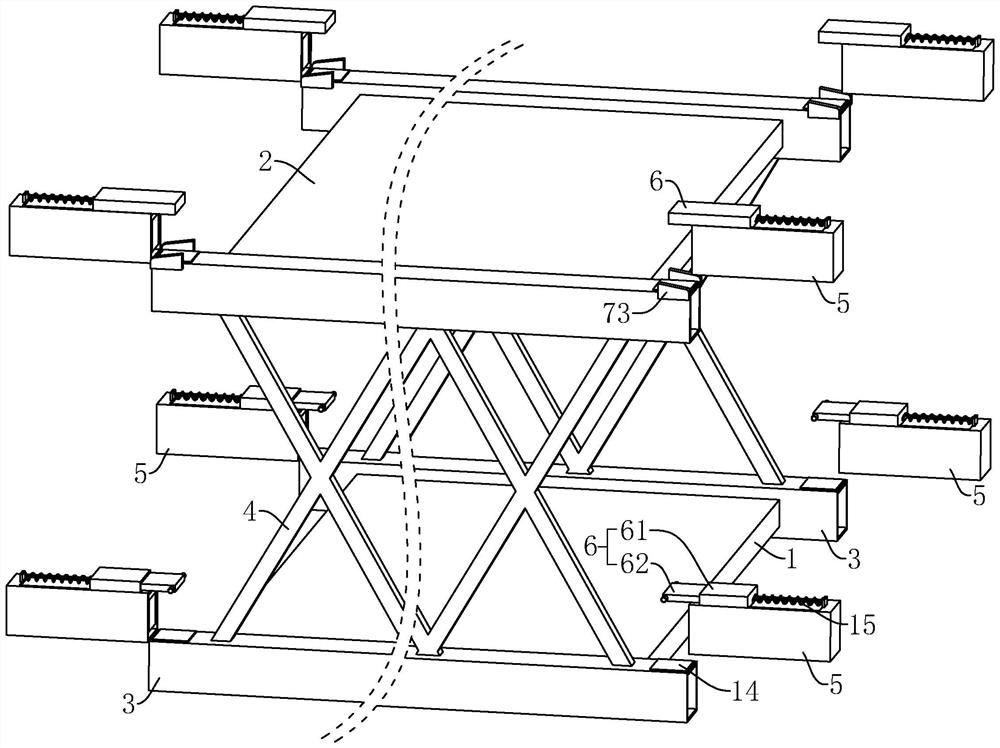

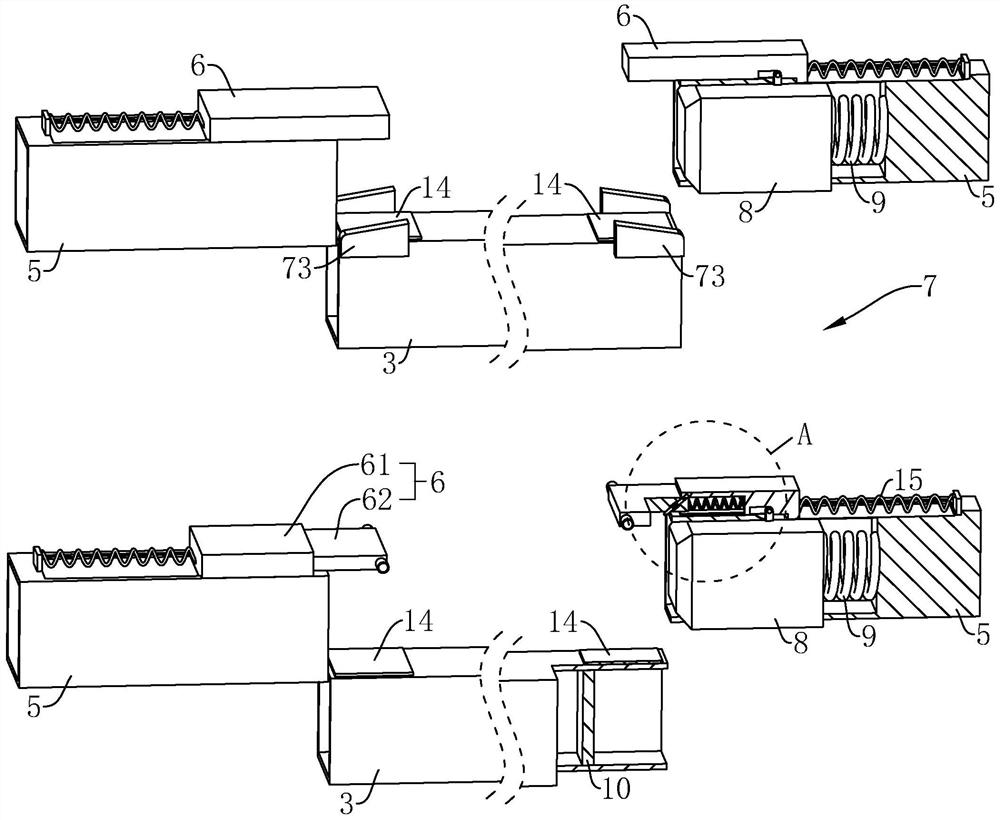

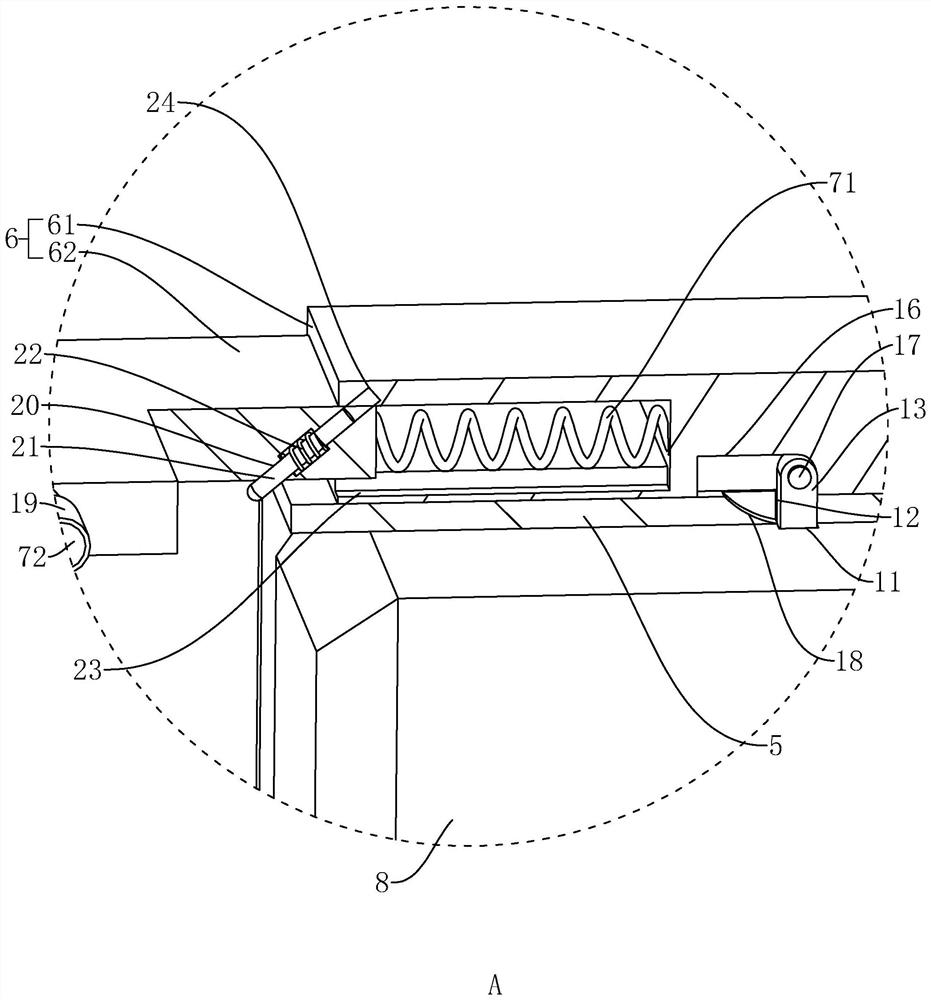

[0036] The following is attached Figure 1-3 The application is described in further detail.

[0037] refer to figure 1, a long-span corridor between buildings of different heights, comprising a horizontal floor 1, a horizontal roof 2 located directly above the floor 1, and horizontal chords welded on both sides of the floor 1 and on both sides of the roof 2 3. The web 4 welded between the two chords 3 on the same side, and the pre-installed tube 5 pre-fixed on the tower, wherein the cross-sections of the chord 3 and the pre-installed tube 5 are square and ring-shaped. After the corridor is assembled on the ground, workers install and debug the hydraulic lifting system, and simultaneously lift both ends of the corridor through the hydraulic lifting system. When the ends of the chord 3 and the corresponding pre-installed pipe 5 are aligned, Workers weld the string tube 3 and the pre-installed tube 5 together with a welding torch, and the corridor is successfully installed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com