Pouring lining lap joint device, tunnel lining trolley and tunnel construction method

A technology of lapping device and lining trolley, which is applied in the direction of tunnel lining, tunnel lining, shaft lining, etc., can solve the problems of concrete cracking lapping, forming irregular pits, and looseness, so as to ensure the construction quality and prevent cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

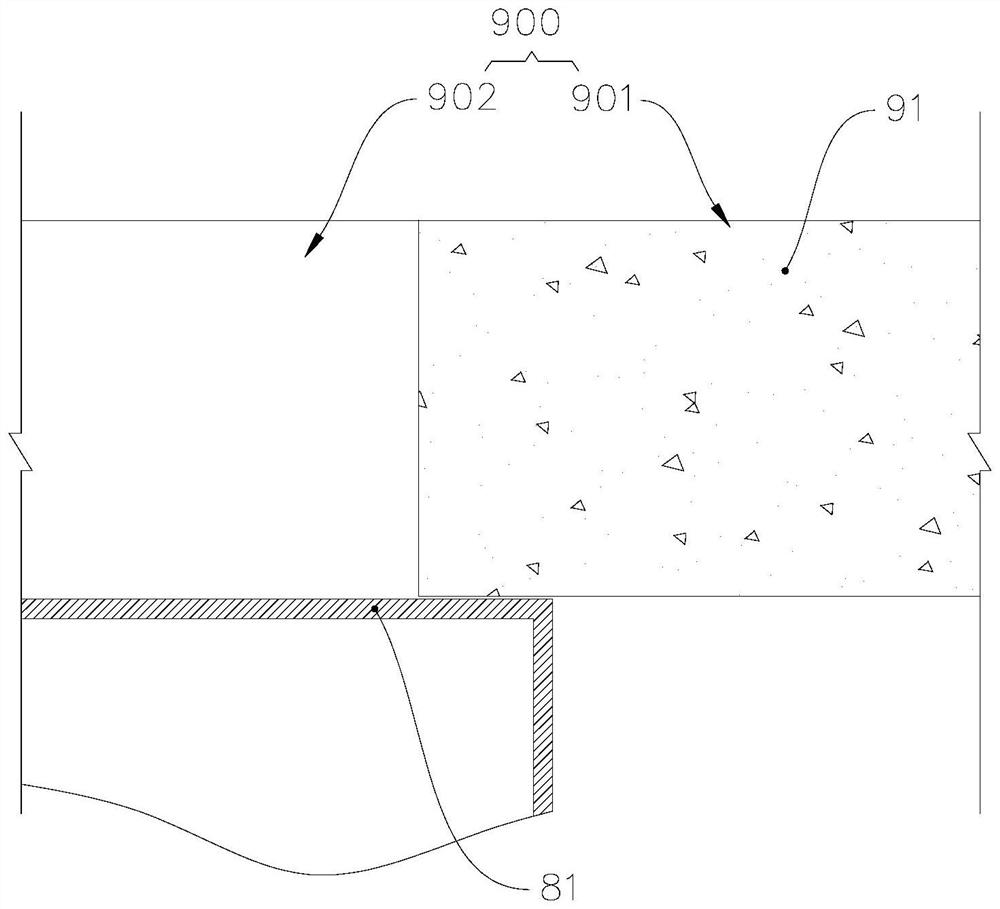

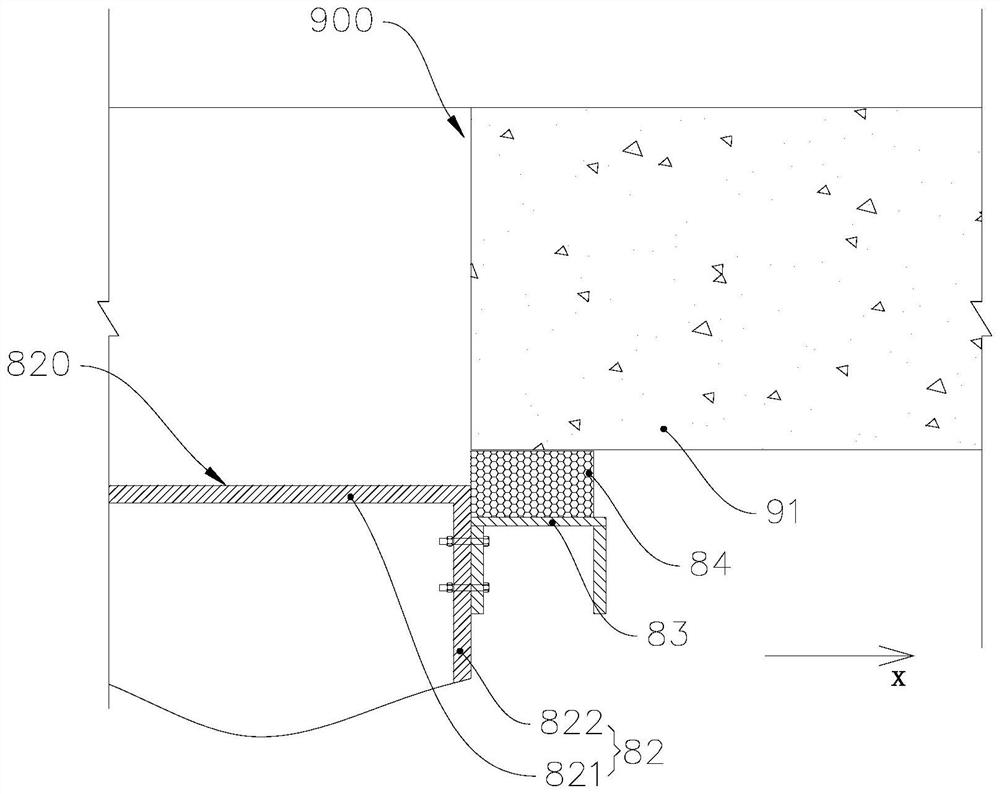

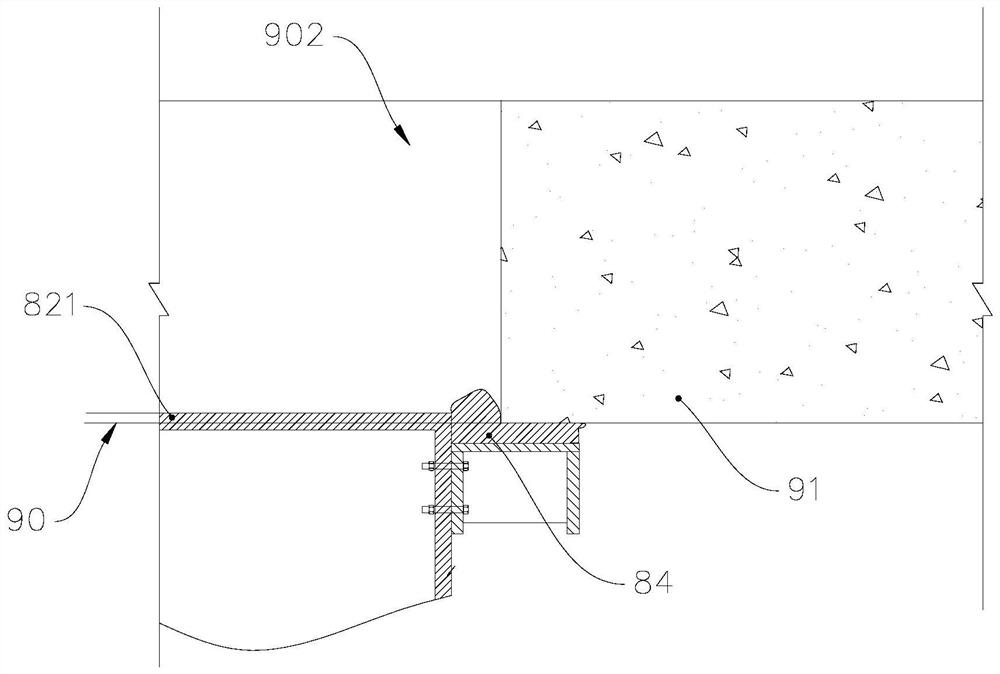

[0038] Example of Tunnel Lining Trolley

[0039] see Figure 5 and Figure 6 , in the coordinate system in the figure, the x-axis direction is the longitudinal direction of the tunnel, the z-axis direction is the height direction and the second direction of the present invention, and the y-axis direction is the transverse direction of the tunnel.

[0040] see Figure 5 , the tunnel lining trolley of the present invention includes a main frame body 11 and a plurality of poured lining overlapping devices 2 of the present invention telescopically connected to the main frame body 11 along the ring direction of the tunnel. Wherein, the lower part of the main frame body 11 is provided with a vertical jacking hydraulic cylinder 121 , and the main frame body 11 is connected with the poured lining overlapping device 2 by a jacking hydraulic cylinder 122 . In addition, an operating platform 13 and a ventilation pipe 14 are also provided in the middle of the main frame body 11 . Of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com