One-way valve with filtering function

A technology of one-way valve and function, applied in the direction of function valve type, filter separation, fixed filter element filter, etc., it can solve the problems of rising opening pressure, non-metallic valve core adhesion, etc., to solve adhesion and improve overall air tightness performance, low flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

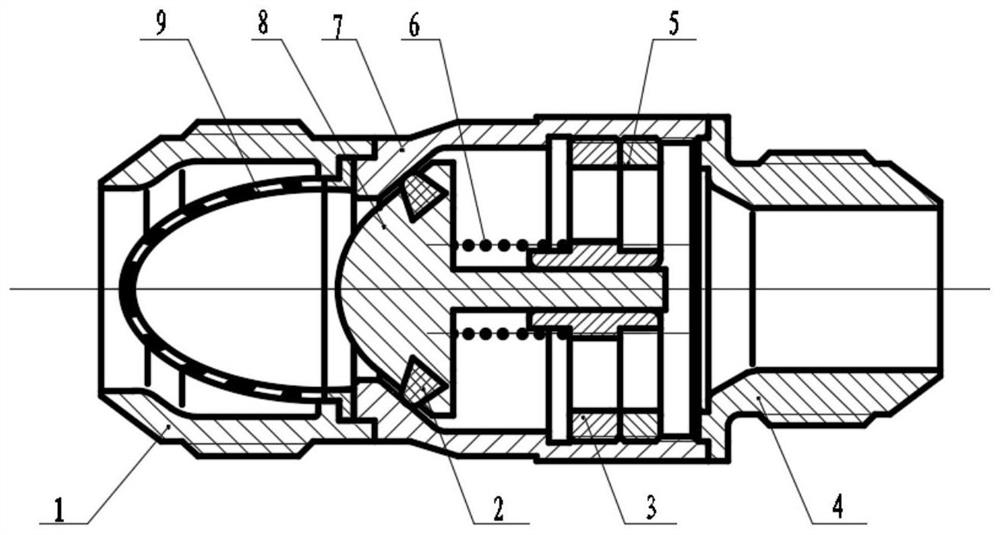

[0010] Such as figure 1 As shown, the one-way valve of the present invention includes the inlet nozzle 1, the housing 7 and the outlet nozzle 4 connected by welding in sequence, and the overall outer contour is welded and formed, and the airtightness is better.

[0011] A filter 9 is installed in the inlet nozzle 1, and after the inlet nozzle 1 presses the filter 9, it is welded with the casing 7 to form a casing assembly, and the casing assembly is connected with the outlet nozzle 4 by welding; the filter 9 is oval Hemisphere, the top of the filter opens towards the inlet nozzle 1, the circular edge of the rear end of the filter is clamped and compressed by the rear end of the inlet nozzle 1 and the front end of the housing 7, and the elliptical profile of the filter 9 can effectively reduce the Flow resistance, the inlet flow channel in the inlet nozzle 1 is trumpet-shaped, the front end is closed, and the cross-section gradually expands backwards. The streamlined design of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com