Oil level gauge calibration device

The technology of a calibration device and an oil level gauge, which is applied in the field of oil level gauge inspection, can solve the problems of low resolution of a magnetic flap liquid level gauge, affecting production, affecting the normal operation of a storage tank, etc., and achieving a small overall volume and easy installation. and disassembly, the effect of easy horizontal position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

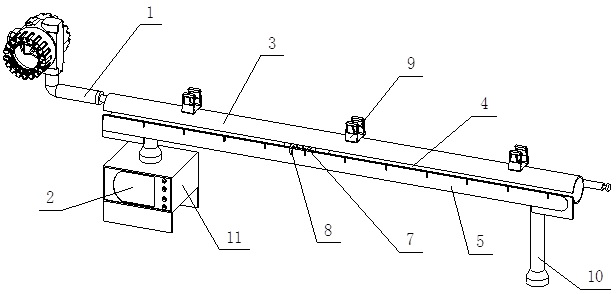

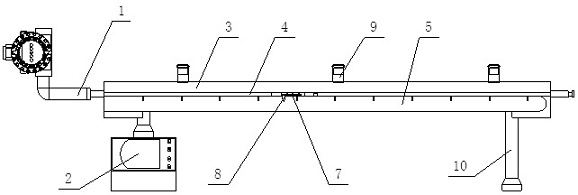

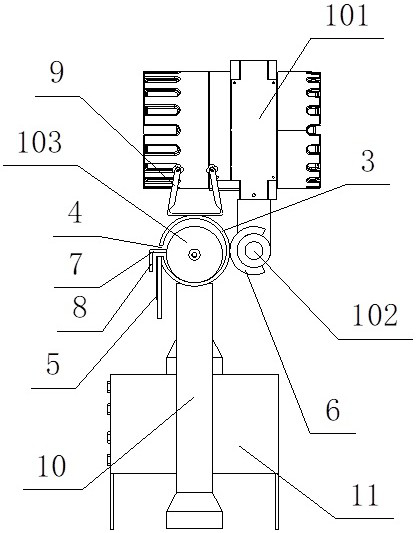

[0023] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the oil level gauge calibration device provided in this embodiment includes a magnetostrictive liquid level gauge 1, a dual-channel digital display 2 and a cylinder body 3. The magnetostrictive liquid level gauge 1 includes a meter head 101, a probe Rod 102 and floating ball 103, the two ends of the cylinder 3 are open, the middle part of one side of the cylinder 3 is provided with a bar-shaped groove 4 that runs through the side wall of the cylinder 3, a steel ruler 5 is provided under the bar-shaped groove 4, and a steel ruler 5 The ruler 5 is parallel to the strip groove 4, the top edge of the steel ruler 5 is flush with the bottom edge of the strip groove 4, the steel ruler 5 is fixedly installed on the outer wall of the cylinder 3, and the floating ball 103 is set in the cylinder Inside the body 3, and cooperate with the gap between the inner wall of the cylinder body 3, a handle 7 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com