Intelligent detection equipment for sensitivity of sound-sensitive sensor

A sound-sensitive sensor, intelligent detection technology, applied in the direction of testing/calibrating volume flow, etc., can solve the problems of inaccurate detection accuracy and constant buzzer power, and achieve good detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

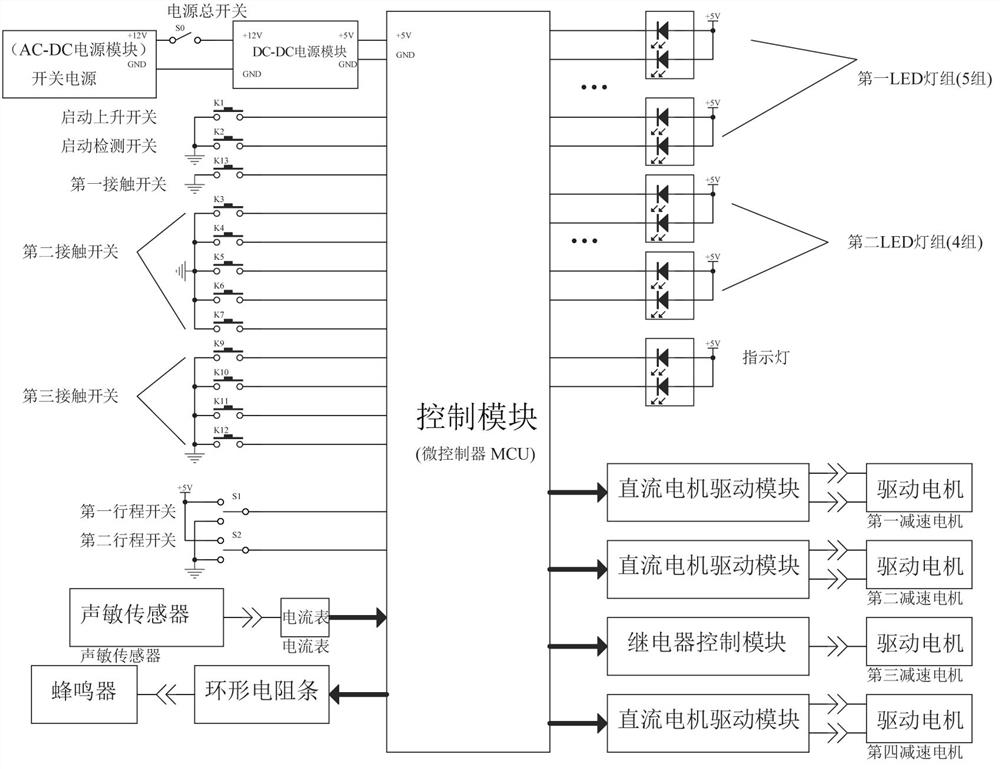

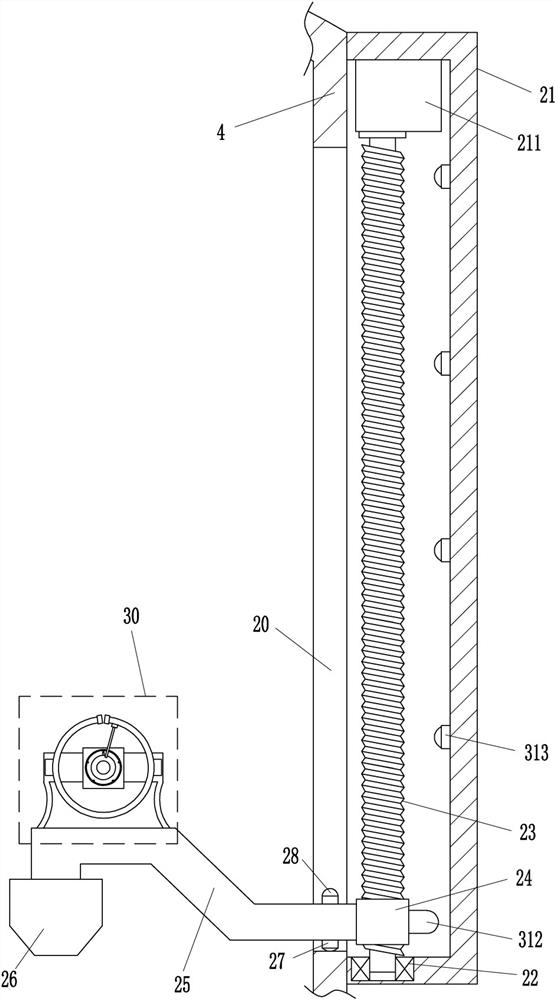

[0020] An intelligent detection device for the sensitivity of an acoustic sensor, such as Figure 1-8 As shown, it includes a wall hanger 1, an installation screw 3, a detection box 4, a first installation box 6, a guide rail 7, a guide sleeve 8, a first nut 9, a first bearing seat 10, a first gear motor 11, a first wire Rod 12, connecting frame 13, power supply board 14, ammeter 16, L-shaped block 17, first contact switch 18, control box 19, main power switch 191, start up switch 192, start detection switch 193, indicator board 194, first LED lamp group 195, the second installation box 21, the second reduction motor 211, the second bearing seat 22, the second screw mandrel 23, the second nut 24, the mounting frame 25, the buzzer 26, the first travel switch 27, the second Two stroke switches 28 and a power adjustment device 30, the upper and lower parts of the wall mount 1 are provided with mounting holes 2, the mounting holes 2 on both sides of the upper and lower sides are e...

Embodiment 2

[0022] An intelligent detection device for the sensitivity of an acoustic sensor, such as Figure 1-8As shown, it includes a wall hanger 1, an installation screw 3, a detection box 4, a first installation box 6, a guide rail 7, a guide sleeve 8, a first nut 9, a first bearing seat 10, a first gear motor 11, a first wire Rod 12, connecting frame 13, power supply board 14, ammeter 16, L-shaped block 17, first contact switch 18, control box 19, main power switch 191, start up switch 192, start detection switch 193, indicator board 194, first LED lamp group 195, the second installation box 21, the second reduction motor 211, the second bearing seat 22, the second screw mandrel 23, the second nut 24, the mounting frame 25, the buzzer 26, the first travel switch 27, the second Two stroke switches 28 and a power adjustment device 30, the upper and lower parts of the wall mount 1 are provided with mounting holes 2, the mounting holes 2 on the upper and lower sides are provided with mo...

Embodiment 3

[0025] An intelligent detection device for the sensitivity of an acoustic sensor, such as Figure 1-8 As shown, it includes a wall hanger 1, an installation screw 3, a detection box 4, a first installation box 6, a guide rail 7, a guide sleeve 8, a first nut 9, a first bearing seat 10, a first gear motor 11, a first wire Rod 12, connecting frame 13, power supply board 14, ammeter 16, L-shaped block 17, first contact switch 18, control box 19, main power switch 191, start up switch 192, start detection switch 193, indicator board 194, first LED lamp group 195, the second installation box 21, the second reduction motor 211, the second bearing seat 22, the second screw mandrel 23, the second nut 24, the mounting frame 25, the buzzer 26, the first travel switch 27, the second Two stroke switches 28 and a power adjustment device 30, the upper and lower parts of the wall mount 1 are provided with mounting holes 2, the mounting holes 2 on the upper and lower sides are provided with m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com