Method for calculating bearing capacity of confined concrete combination column under action of bias pressure

A technique of confining concrete and calculation methods, applied in design optimization/simulation, instrumentation, electrical digital data processing, etc., can solve problems such as insufficient ferrule function, poor prediction of bias bearing capacity, and buckling of steel pipe walls, etc., to achieve Widely promote the value and application prospects, improve the integrity, and reduce the effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 4

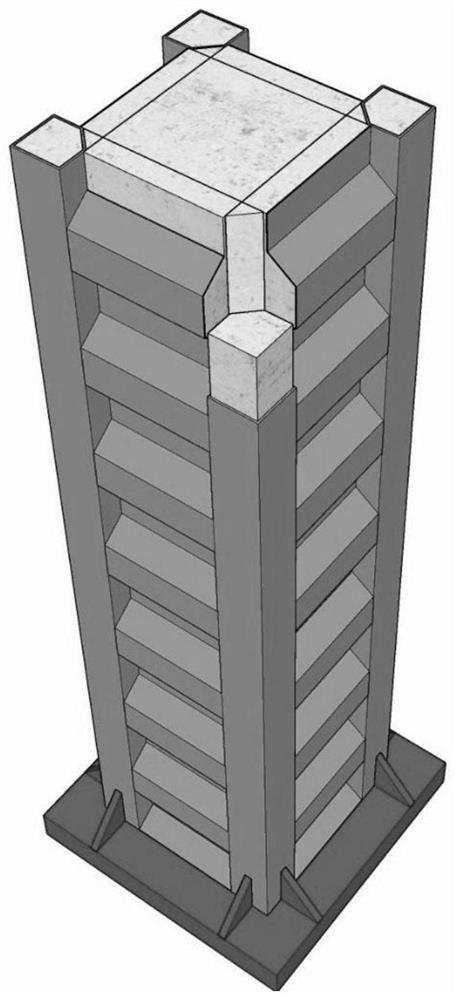

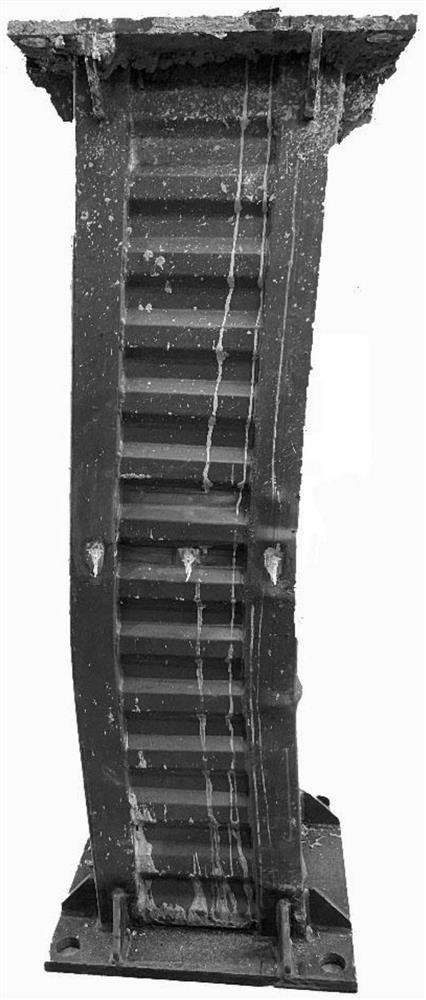

[0139] The constrained concrete composite column is made of C30 concrete, and the measured axial compressive strength design value is 33.24MPa; the corrugated plate and polygonal steel pipe are made of Q345 steel, and the measured yield strength design value is 386.33MPa; the wall thickness of the polygonal steel pipe is 3mm, and the corrugated The thickness of the plates was 1.2 mm, and the eccentricities were 0.2, 0.4, 0.6 and 0.8, respectively. The test values of the bearing capacity of the restrained concrete composite column under bias pressure are 3300kN, 3000kN, 2800kN, 2352kN respectively, and the formula values obtained by the calculation method proposed by the present invention are respectively 3341.24kN, 2908.47kN, 2815.33kN, 2259.64kN, Good fit.

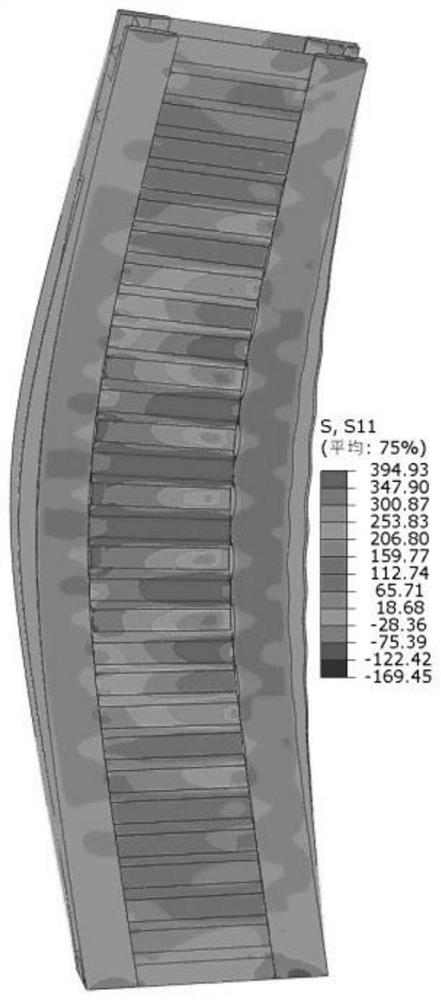

[0140] Due to the uncertainty in the test process and the large loss, the eccentric bearing capacity of the confined concrete composite column obtained by ABAQUS finite element simulation is compared with the calculat...

Embodiment 5- Embodiment 9

[0142] Embodiment 5-Example 9 are comparisons of the ultimate bearing capacity of each eccentric test piece under different steel pipe thicknesses and the calculated value of the formula. The specific structural parameters and the bearing capacity calculated with the ABAQUS finite element software are shown in Table 2.

Embodiment 10- Embodiment 21

[0144] Embodiment 10-Example 21 is a comparison of the ultimate bearing capacity of each eccentric specimen under different steel pipe strengths and the calculated value of the formula. The specific structural parameters and the bearing capacity calculated with the ABAQUS finite element software are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com