Load feedback jet pulse water dropper and drip irrigation system

A technology of load feedback and jet flow, which is applied in watering devices, gardening, agriculture, etc., can solve the problems of incomplete jet flow commutation and small amplitude, and achieve the effects of low processing cost, convenient construction and operation, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

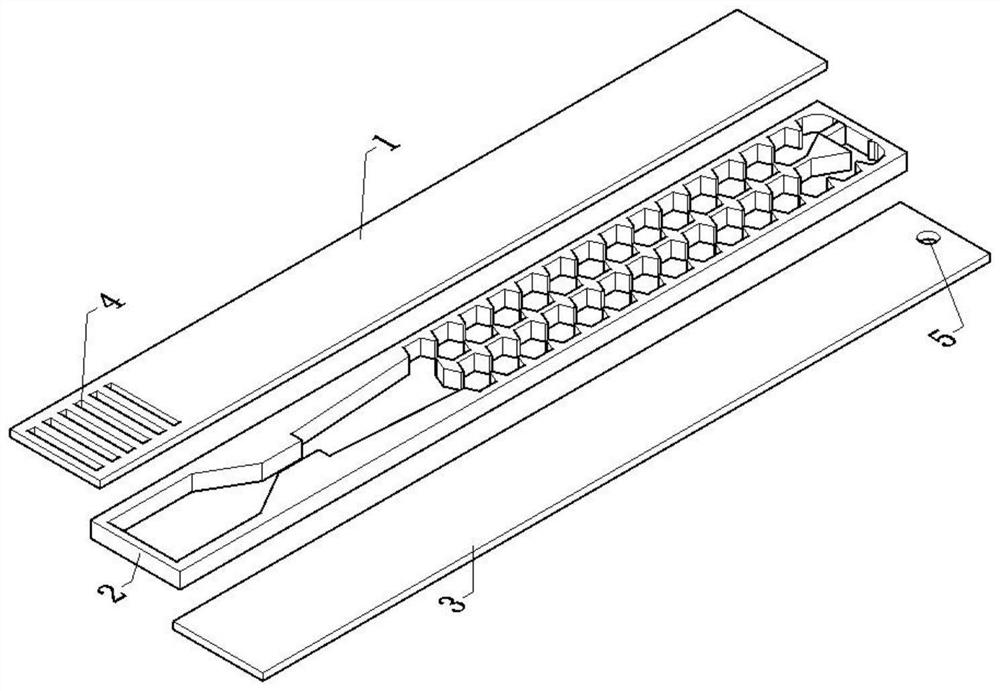

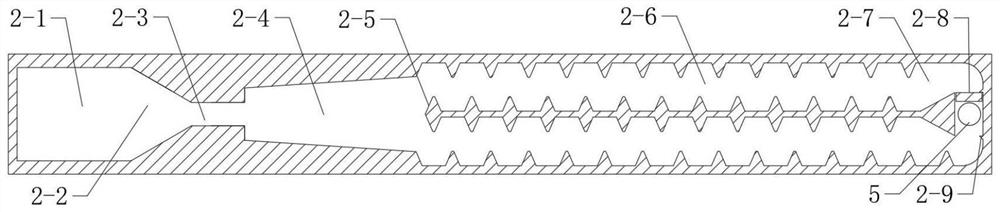

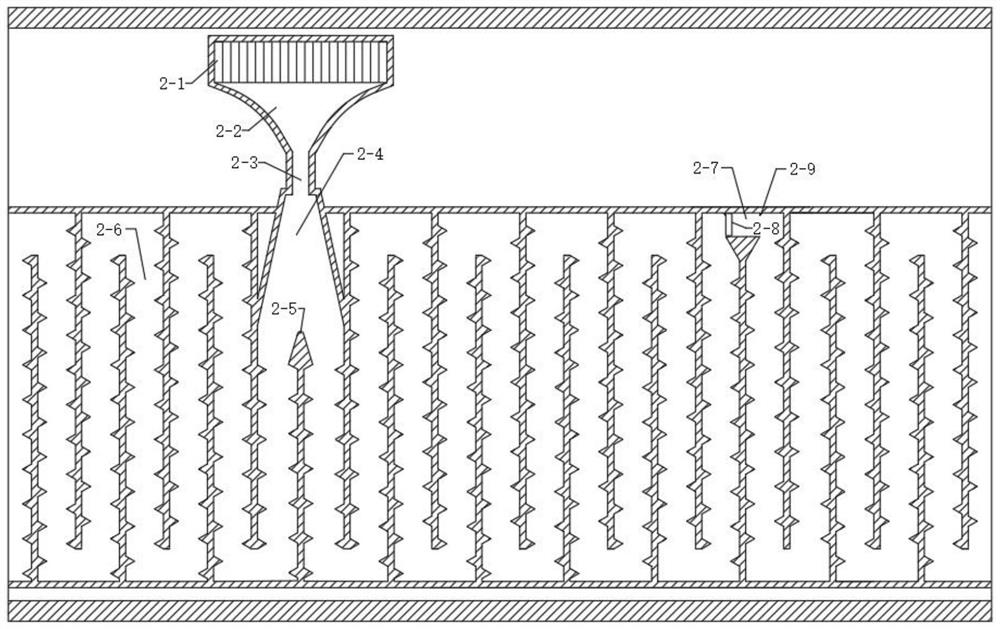

[0036] Such as Figure 1-Figure 2 As shown, this embodiment provides a load-feedback jet pulse dripper, preferably a sheet-type load-feedback jet pulse dripper, which mainly includes an upper plate 1, a main body 2 and a lower plate 3; the upper plate 1 is provided with a filter inlet 4, The lower plate 3 is provided with a water outlet hole 5; the main body 2 is provided with a water inlet chamber 2-1, a contraction section 2-2, a jet tube 2-3, a jet space 2-4, a splitter 2-5, and a labyrinth channel 2 -6 and the water outlet chamber 2-7; the water inlet chamber 2-1 is located at the front end of the main body 2, and communicates with the filter inlet 4 to realize water intake; the end of the water inlet chamber 2-1 is connected with a conical contraction section with a large front and a small rear 2-2, the end of the contraction section 2-2 is connected to a rectangular jet tube 2-3, and the end of the jet tube 2-3 is connected to a trapezoidal jet space 2-4 with a small fro...

Embodiment 2

[0046] This embodiment is an improvement made on the basis of Embodiment 1, and its improvements are as follows: Figure 3-Figure 4 As shown, the load feedback jet pulse dripper is a cylindrical load feedback jet pulse dripper, and the splitter 2-5 of the cylindrical load feedback jet pulse dripper divides the jet space 2-4 into two channels, and the two labyrinth flow channels 2 The front ends of -6 communicate with two adjacent passages respectively, wherein the labyrinth passage may include a plurality of vertical passages connected in sequence from end to end.

[0047] When the cylindrical load feedback jet pulse dripper is set in the drip irrigation pipeline, the outer surface of the cylindrical load feedback jet pulse dripper is embedded on the inner wall of the drip irrigation pipeline, and corresponds to the position of the center of the water outlet cavity 2-7 on the drip irrigation pipeline wall surface Opening, the area of the opening is smaller than the minimum f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com