Tool for boring outer circle of large workpiece

A large-scale workpiece and tooling technology, applied in the field of large-scale parts boring outer circle tooling, can solve the problems of shaft deformation, cost increase, bearing crushing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

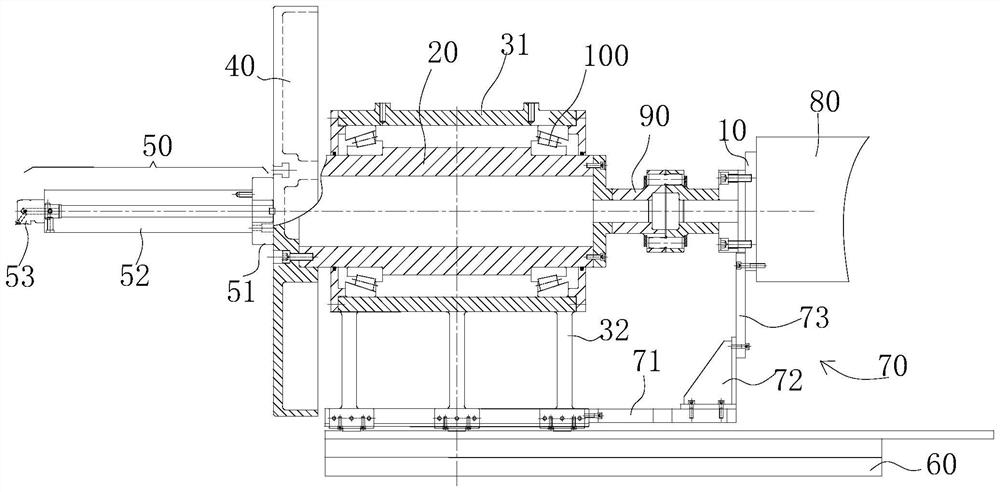

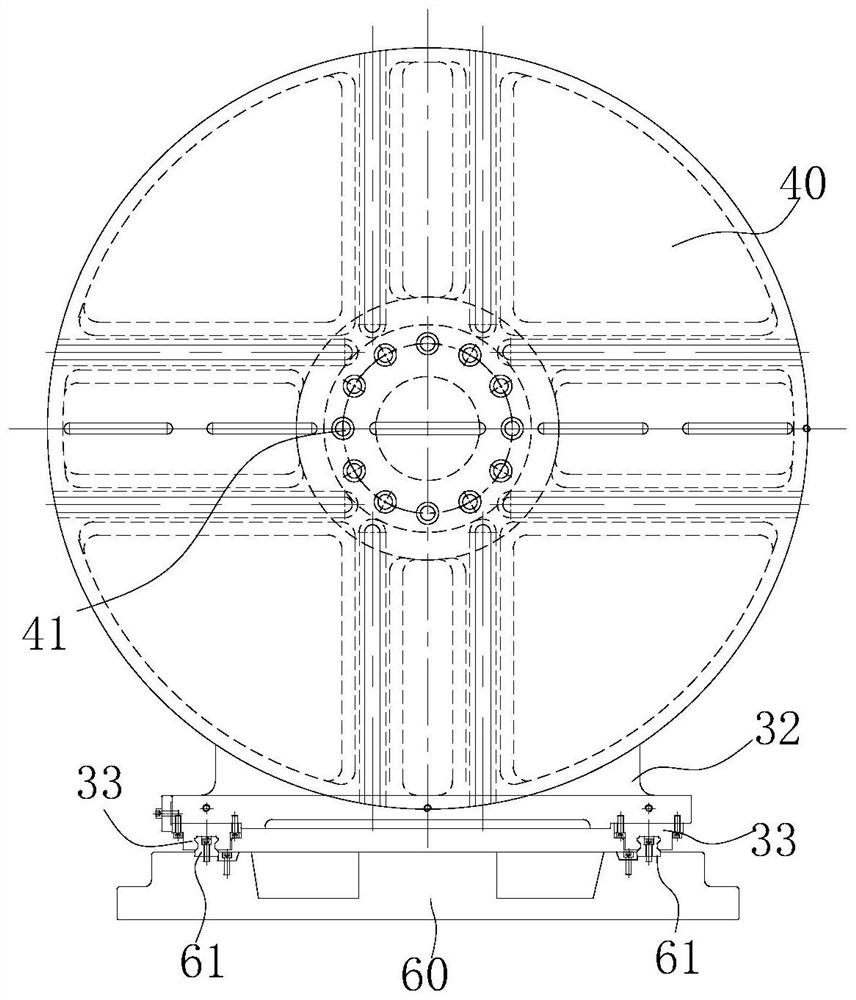

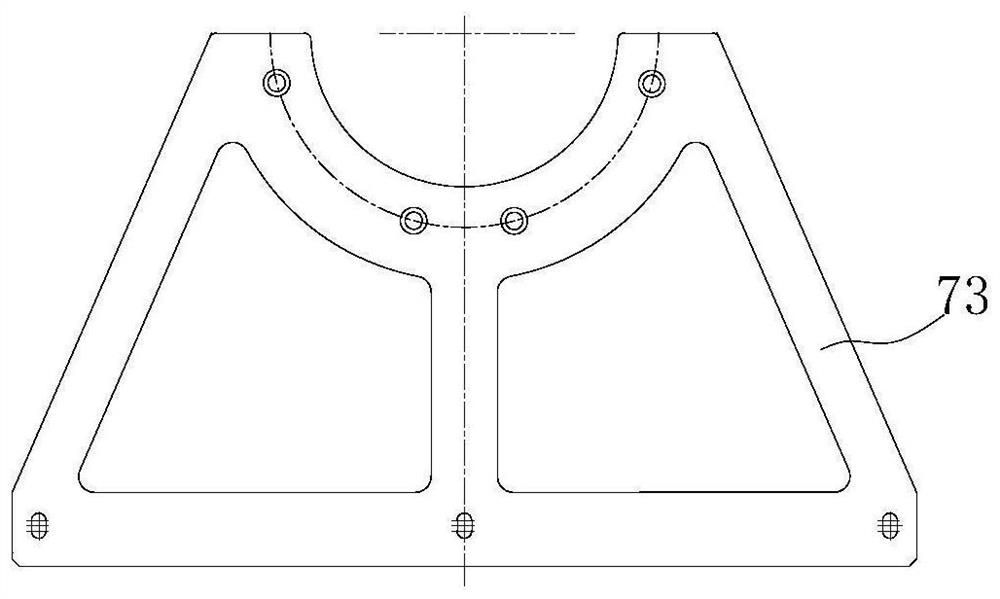

[0009] like Figure 1-Figure 3 As shown, a large-scale workpiece boring outer circle tooling includes a machine tool spindle 10 whose axis center is located in the horizontal direction. The front end of the machine tool spindle 10 is coaxially connected with a rotating shaft 20. A chuck 40 is provided, and a boring tool assembly 50 protrudes from the chuck 40 to the front side. For large workpieces, the diameter of the outer circle is large and the length is long. If a large-diameter chuck is directly added to the rotating shaft, the eccentric distance of the boring tool assembly on the chuck is too large relative to the rotating shaft. In addition, the length of the large workpiece is too long, so the force arm of the boring tool assembly should be set very long accordingly. During processing, the rotating shaft of the boring machine has to carry a large torque, which is easy to appear. Risk of shaft deformation. Therefore, in this application, the most frequently used mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com