Preparation method of light alloy three-dimensional lattice sandwich structure based on high surface quality

A three-dimensional lattice and sandwich structure technology, which is applied in the field of preparation of three-dimensional lattice sandwich structures based on high surface quality light alloys, can solve the problems of reducing the overall strength of the three-dimensional lattice structure, limiting the lightweight degree of the three-dimensional lattice structure, etc. The probability of occurrence of small defects, the reduction of peak air pressure, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

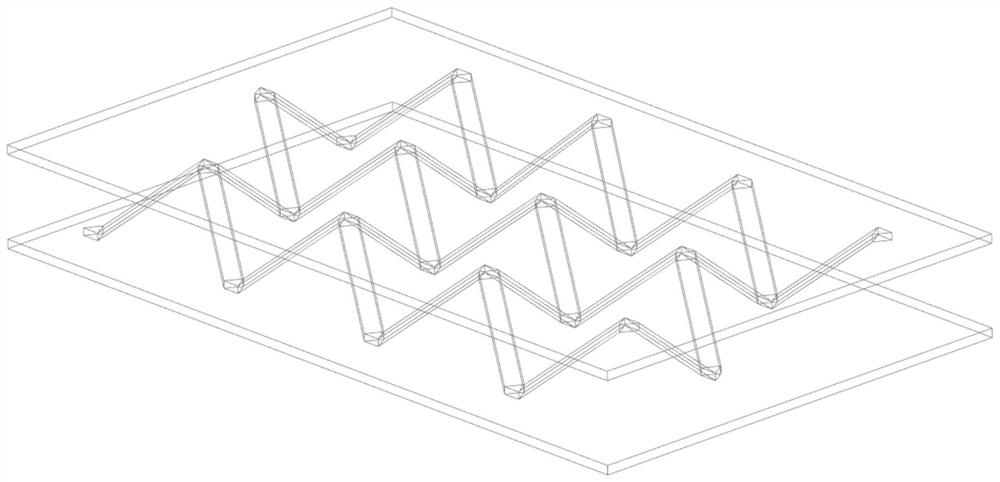

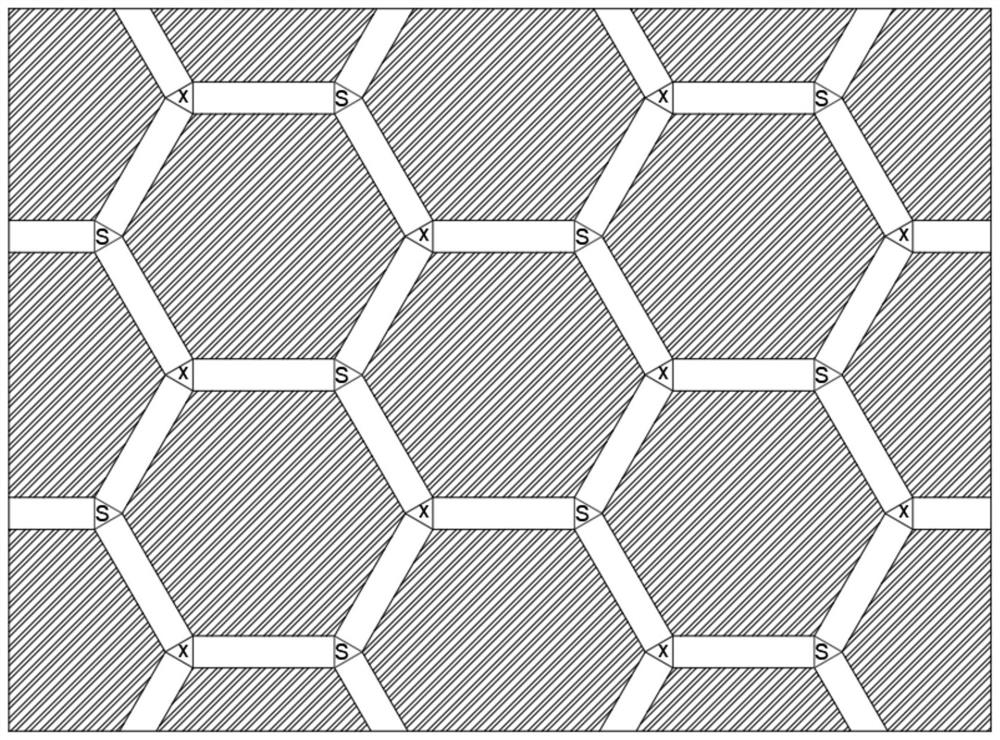

[0023] Specific implementation mode one: refer to Figure 1 to Figure 2 To illustrate this embodiment, this embodiment provides a method for preparing a three-dimensional lattice sandwich structure based on a light alloy with high surface quality, and the method is realized through the following steps:

[0024] Step 1: Fine-grained core plate processing; first select the fine-grained light-weight alloy plate with fine grains, and process the fine-grained light-weight alloy plate into a grid-shaped hollow structure according to the design plan by mechanical processing methods, and according to the design plan in the Ventilation holes are processed at the corresponding positions of the core board;

[0025] Step 2: Processing of the upper panel and the lower panel; the material of the upper and lower panels is selected from ordinary light alloy plates, and the upper panel and the lower panel are processed according to the outline of the fine-grained core board. There is no need t...

specific Embodiment approach 2

[0034] Specific implementation mode two: refer to Figure 1 to Figure 2 Describe this embodiment, this embodiment is to further limit the step 1 described in the specific embodiment 1. In this embodiment, the laser cutting method is used in the step 1 to process the fine-grained light alloy plate according to the requirements of the design plan. Grid-shaped hollow structure, and process air holes at the corresponding positions of the core board according to the design plan. Other compositions and method steps are the same as those in Embodiment 1.

specific Embodiment approach 3

[0035] Specific implementation mode three: refer to Figure 1 to Figure 2 Describe this embodiment, this embodiment is to further limit the step three described in the second specific embodiment, in this embodiment, in the step three, 180 mesh, 240 mesh, 400 mesh, 800 mesh, 1200 mesh and 1500-grit sandpaper is used to polish the surface of the upper panel, the lower panel and the fine-grained core board, and each surface of the lower surface of the upper panel, the upper surface of the lower panel and the fine-grained core board needs to be polished six times. Other compositions and method steps are the same as those in Embodiment 2.

[0036] Such setting is convenient to ensure that the surface of the plate body is smooth and smooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com