Locking mechanism and servo turntable

A technology of locking mechanism and locking parts, which is applied in the direction of metal processing machine parts, metal processing equipment, manufacturing tools, etc., can solve the problems of poor sensitivity, adverse effects of processing accuracy, uneven distribution of turntable braking force, etc., and achieve improved stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

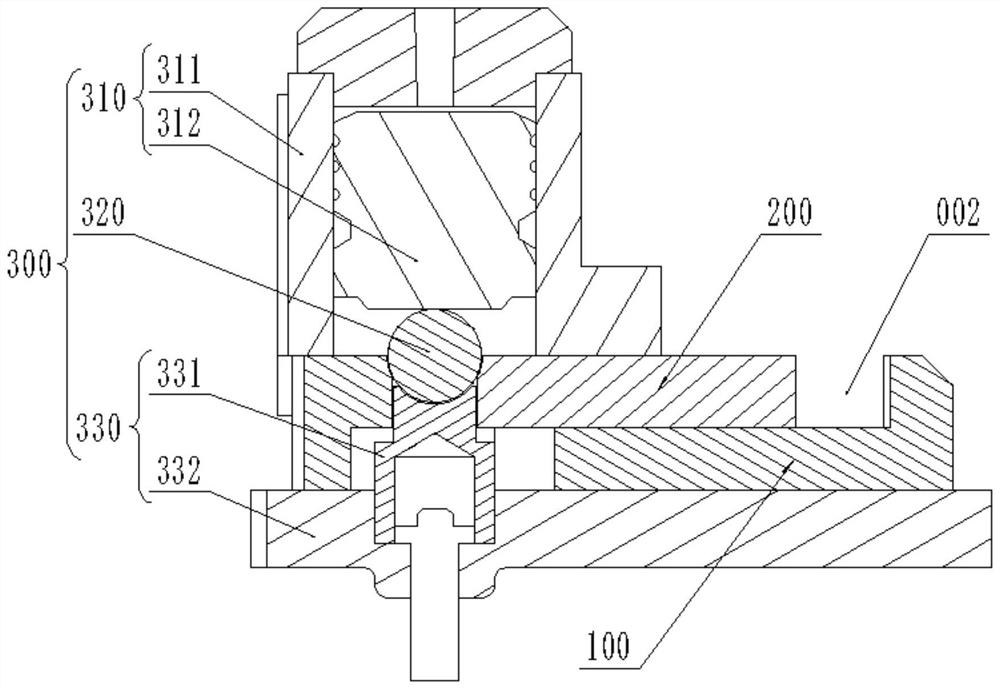

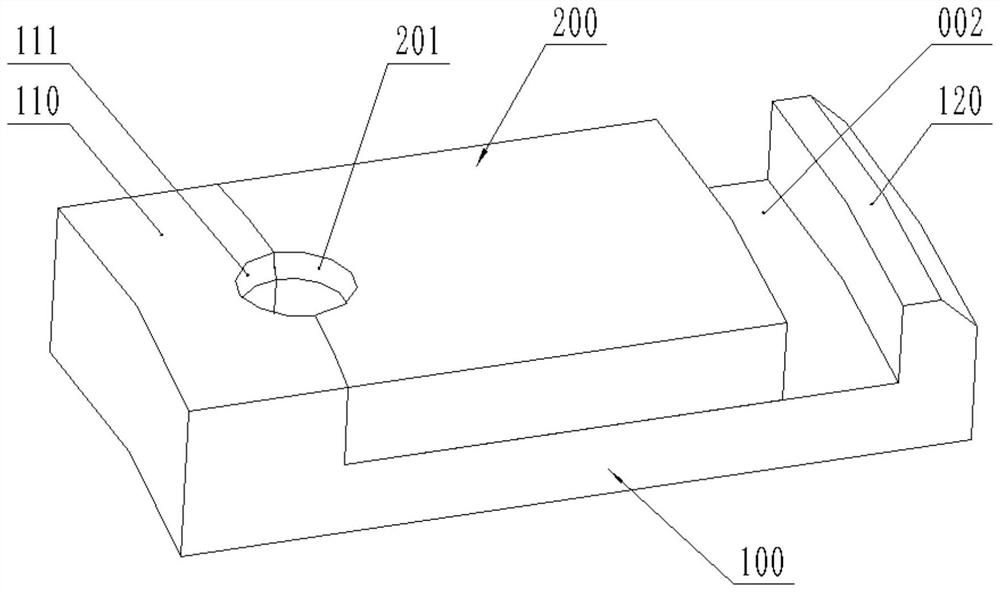

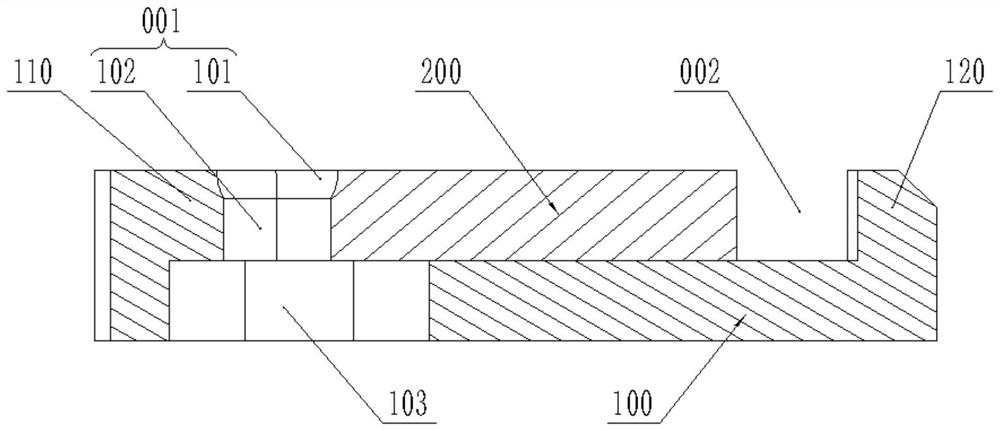

[0039] Such as figure 1 , figure 2 and image 3 As shown, the locking mechanism provided by the embodiment of the present invention includes: an outer circular locking member 100, an inner circular locking member 200 and a tensioning device 300; the outer circular locking member 100 is provided with a base portion 110 and a clamping portion 120, the base part 110 and the clamping part 120 are arranged at intervals; the inner circular locking part 200 is installed between the base part 110 and the clamping part 120, and an expansion squeeze is formed between the base part 110 and the inner circular locking part 200 The clamping area 001, the clamping area 002 is formed between the clamping part 120 and the inner circular locking member 200; spacing is reduced.

[0040] Specifically, the tensioning device 300 can extend into the expansion extrusion zone 001, and the base part 110 and the inner circle locking part 200 can be squeezed by the tensioning device 300, so that the ...

Embodiment 2

[0059] Such as figure 1 , Figure 4 and Figure 5 As shown, the servo turntable provided by the embodiment of the present invention includes: a machine base 400, a workbench 500, a turntable 600 and the locking mechanism provided in the above embodiment; Connection; the turntable 600 is inserted in the clamping area 002 .

[0060] Specifically, multiple locking mechanisms are provided, and multiple locking mechanisms are arranged at intervals along the circumferential direction of the turntable 600. Through multiple locking mechanisms, the turntable 600 is clamped or released at the same time, so that the braking force received by the turntable 600 can Evenly distributed along the circumference improves the stability and reliability of locking, and helps to keep the workbench 500 stable during processing.

[0061] In the embodiment of the present invention, the machine base 400 is equipped with a worm driving device 700 , and the turntable 600 is equipped with a worm gear 8...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap