Calendaring forming device for preparing anti-sticking gas mold material

A technology of air mold material and calendering, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as lack of adhesive cleaning measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

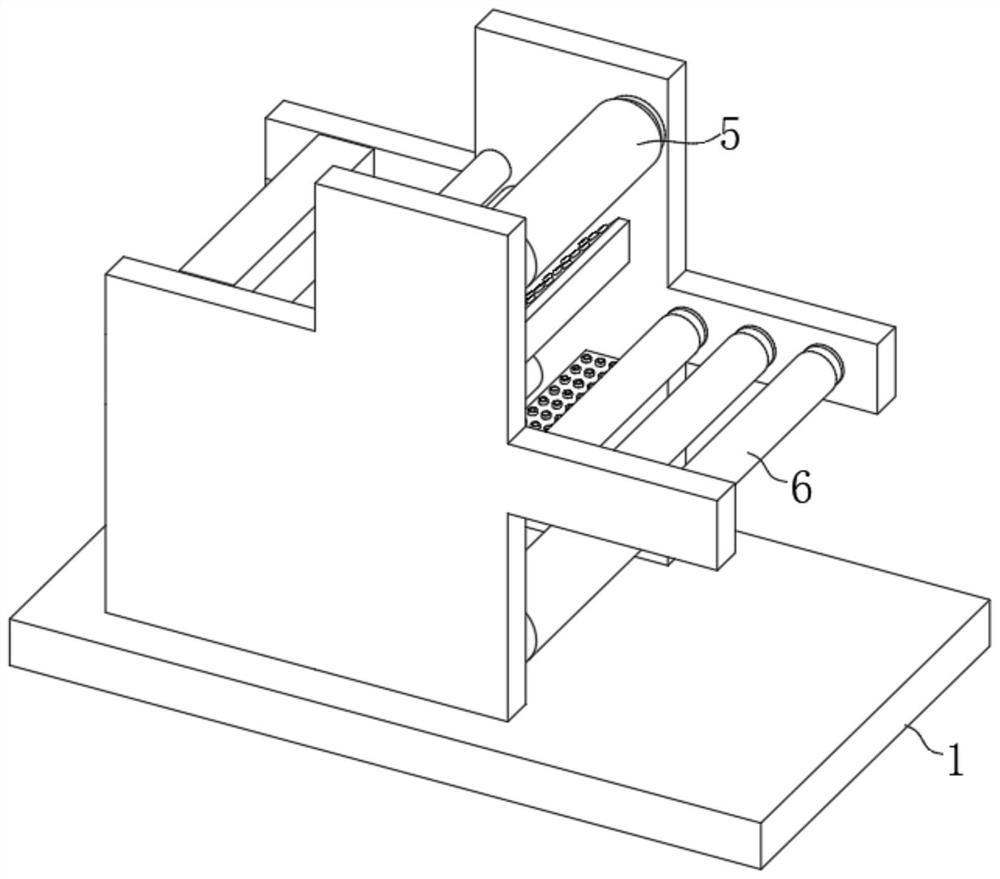

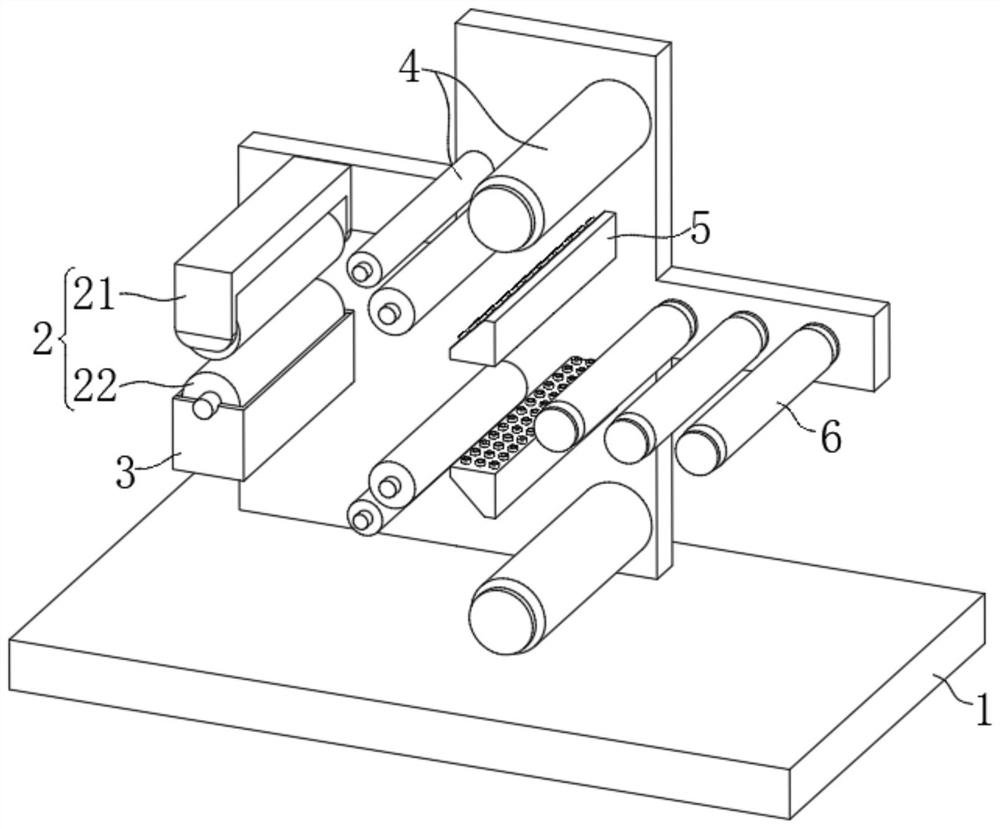

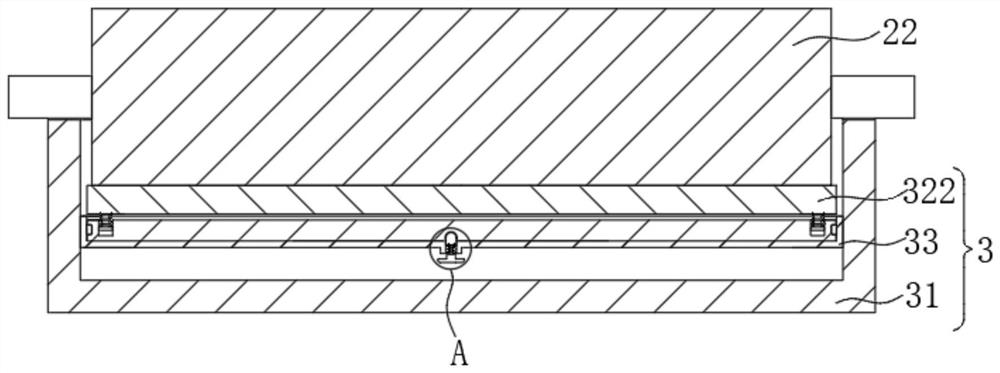

[0041] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 ,in, figure 1 It is a schematic structural diagram of the first embodiment of the calendering device for preparing anti-adhesive inflatable mold materials provided by the present invention; figure 2 for figure 1 The structural schematic diagram of the inside of the main frame shown in ; image 3 for figure 1 The schematic diagram of the structure inside the box is shown; Figure 4 for image 3 The enlarged schematic diagram of part A shown; Figure 5 for image 3 Sectional view of plane A-A shown. Anti-sticking Calendering equipment for the preparation of inflatable materials, including:

[0042] Main frame 1

[0043] Pressing structure 2, described pressing structure 2 is arranged between the both sides of described main frame 1 inner wall, described pressing structure 2 comprises upper pressing roller 21 and lower pressing roller 22;

[0044] Cleaning structure 3, described cleanin...

no. 1 example 1

[0069] Please refer to Figure 6 , based on the first embodiment of the present invention, a calendering device for preparing an anti-adhesive inflatable material, the second embodiment of the present invention provides another calendering device for preparing an anti-adhesive inflatable material, wherein the second embodiment It does not hinder the independent implementation of the technical solution of the first embodiment.

[0070] Concretely, the present invention provides another kind of anti-adhesive inflatable mold material preparation calender molding device difference in that:

[0071] The top of the base plate 321 is equipped with an electromagnet 7, and the bottom of the contact scraper 322 is equipped with a metal sheet 8. After the electromagnet 7 is energized, it can attract the metal sheet 8 downward.

[0072] The electromagnet 7 is externally connected with a power supply, and its use is controlled by an external switch. When the cleaning structure 3 is in nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com