Electric drive anti-slip protection control method based on whole vehicle TCS working condition

A technology of protection control and electric drive, which is applied in the direction of control drive, electric vehicle, electric energy management, etc. It can solve the problems of unable to control effective protection of electric drive system, unable to meet the demand torque adjustment accuracy, unable to meet the torque fast response, etc., to achieve timely Effective torque response effect, easy hardware cost, effect of ensuring driving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

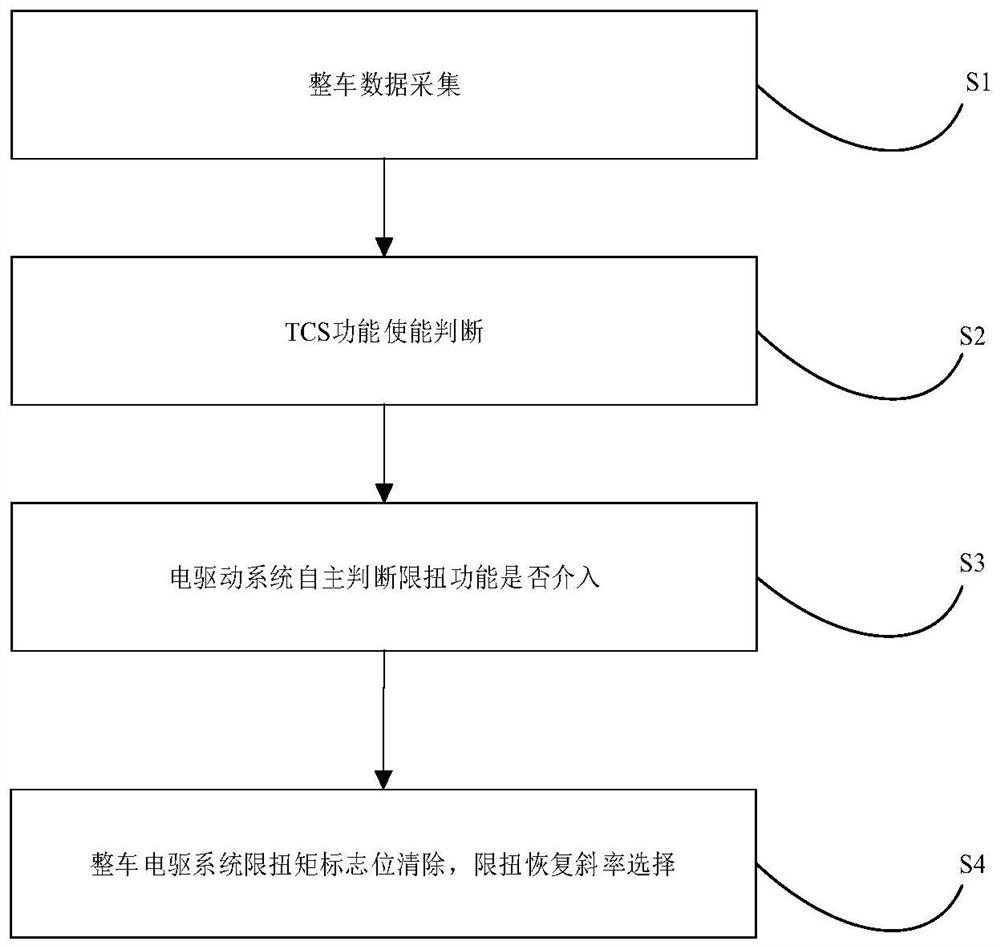

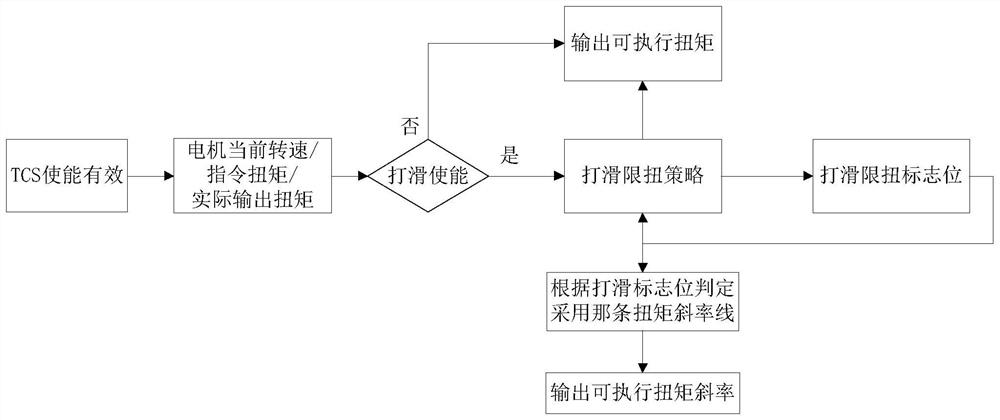

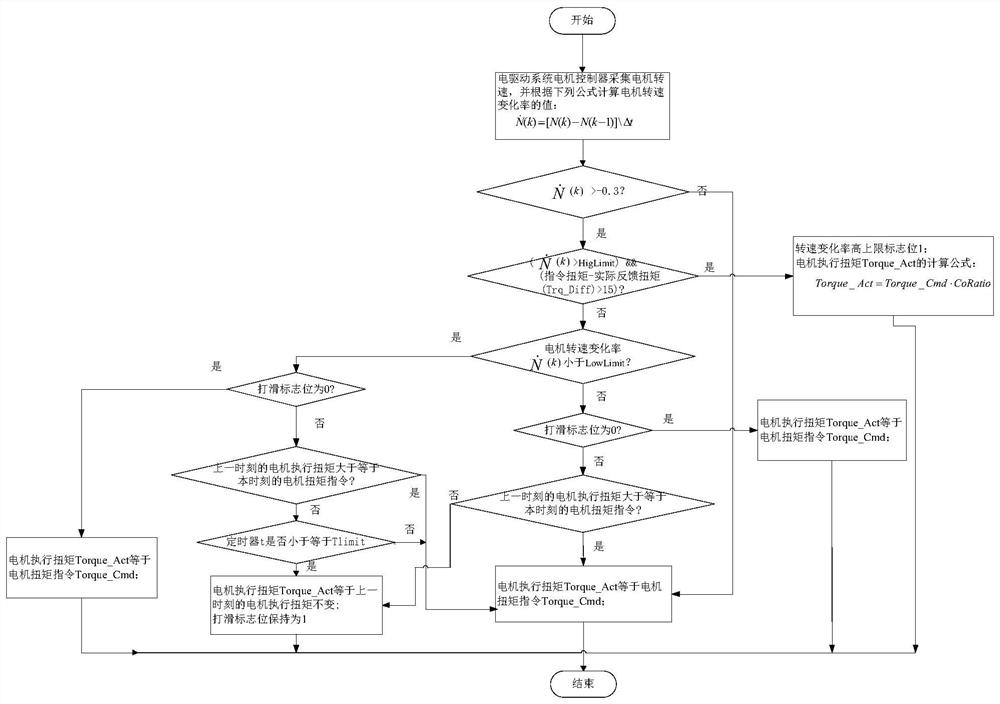

[0037] Such as figure 1 As shown, the electric drive anti-skid protection control method based on the TCS working condition of the whole vehicle of the present invention uses components including a vehicle data acquisition module, a TCS function enabling module, an electric drive slip torque limit control module, and a slip torque limit sign Clearing module; the vehicle data acquisition module is mainly through the real-time acquisition of CAN bus to obtain signals such as vehicle speed and rotating speed to feed back to the TCS function enabling module; the TCS enabling module determines whether the current working condition needs TCS function intervention after data processing, and Output its functional validity flag; the slip torque limiting module of the electric drive system limits the torque according to the TCS enabling effectiveness and actual working conditions, outputs the limited torque in time, and judges the response of the limited torque through the limited flag; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com