Vacuum packaging equipment and method for common sponge

A vacuum packaging and sponge technology, applied in the field of vacuum packaging equipment for ordinary sponges, can solve the problems of arm soreness and the inability of staff to work for a long time, and achieve the effect of convenient operation and reduction of manual operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

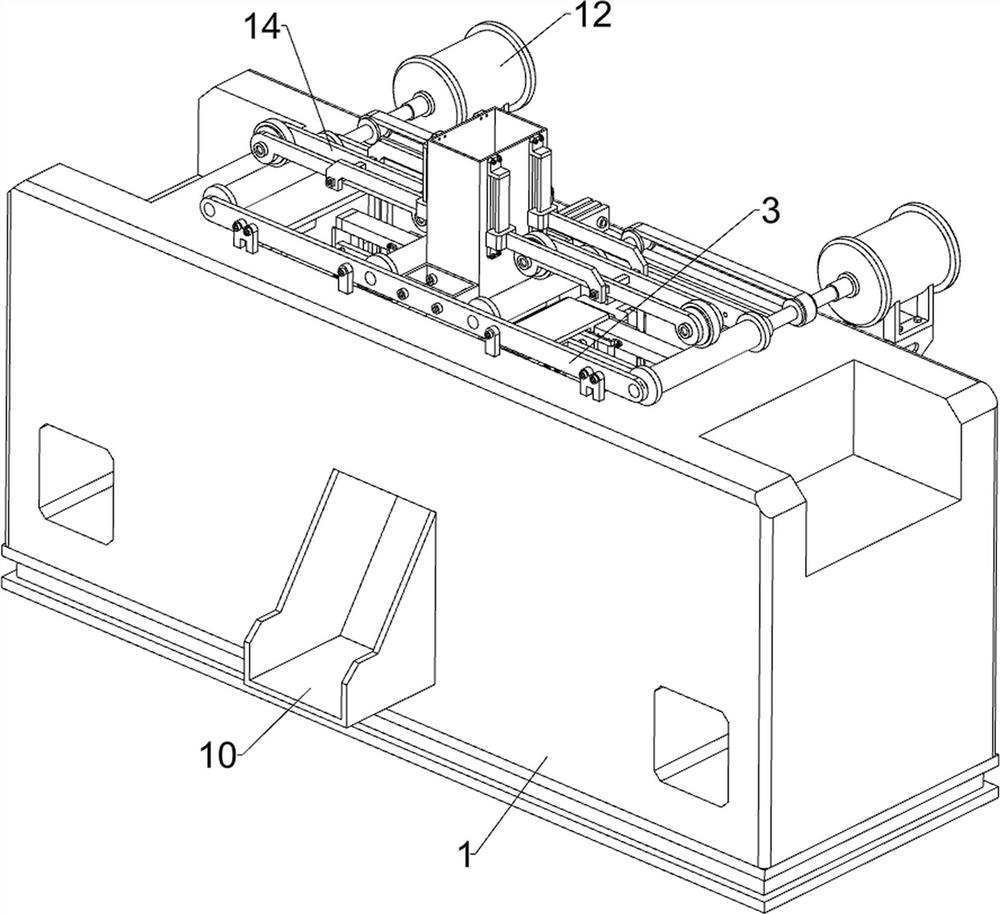

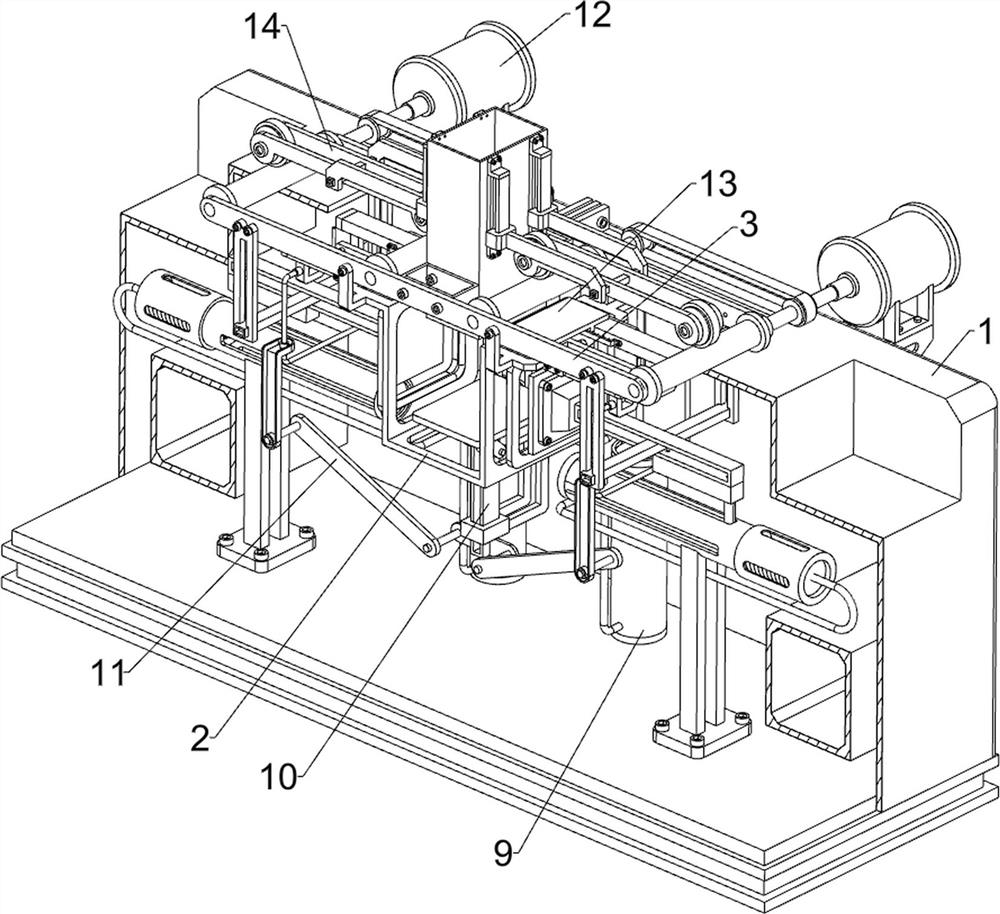

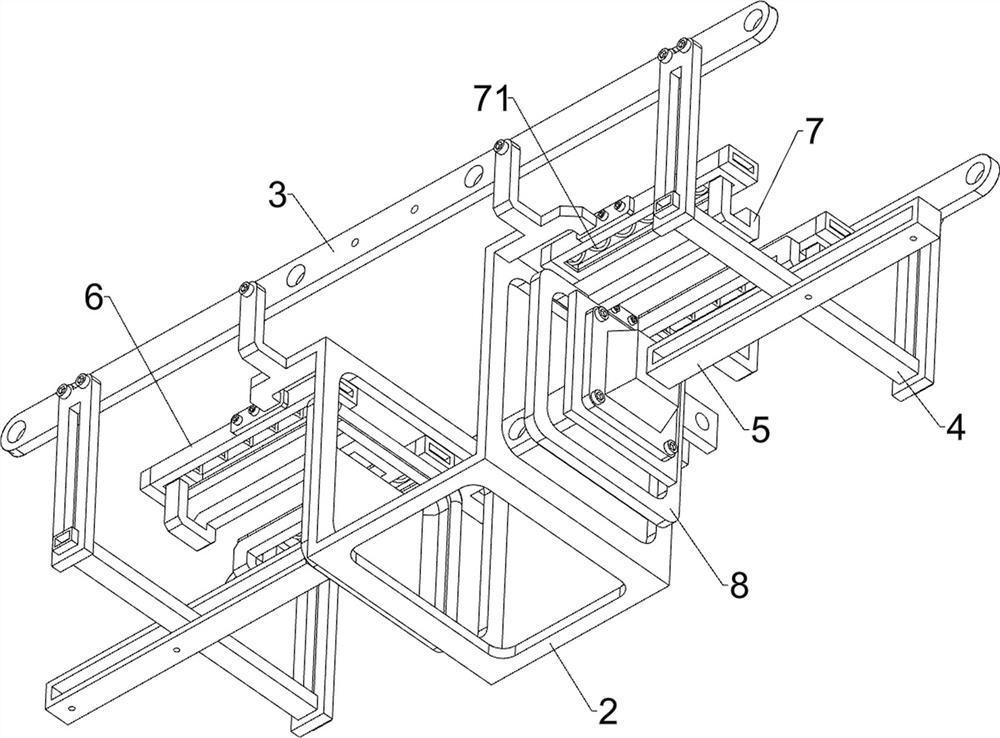

[0037] A vacuum packaging equipment for ordinary sponges, such as Figure 1-15As shown, it includes a housing 1, a frame 2, a strip plate 3, a guide block 4, a pressure plate 5, a first slide rail 6, a sliding frame 7, a first spring 71, a sealer 8, a push assembly 9 and a support assembly 10 , the upper middle part of the housing 1 is provided with a frame 2 by means of welding, and the upper part of the frame 2 is symmetrically fixed with strip plates 3 by bolts, and the left and right sides of the strip plates 3 are connected with guides by means of screw installation. Block 4, the middle part of the guide block 4 is slidingly provided with a pressure plate 5 that can flatten the sponge. On the inner side, a sliding frame 7 is slidably connected between the first sliding rails 6 on the left and right sides, and a first spring 71 is connected between the sliding frame 7 and the adjacent first sliding rails 6, and the inner ends of the sliding frame 7 are There is a sealer 8...

Embodiment 2

[0048] A vacuum packaging method for common sponges, comprising the following steps:

[0049] (1) Prepare materials, prepare the sponge that needs to be packed and the packaging bag for storing the sponge;

[0050] (2) Encapsulation, place the sponge on the placement board 105, hang the packaging bag on the left and right sides of the sponge, press the sponge 5 to flatten the sponge to discharge the air, and at the same time make the packaging bag and the sponge fit together, pass through the sealer 8. The packaging bag is sealed to obtain the vacuum-packed sponge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com