Temporary distilled water preparation device for operating room

A distilled water and operating room technology, applied in the field of temporary distilled water preparation devices in the operating room, can solve problems such as inconvenient operation, long waiting time for distilled water, and insufficient supply of distilled water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will be further described below with reference to the specific embodiments:

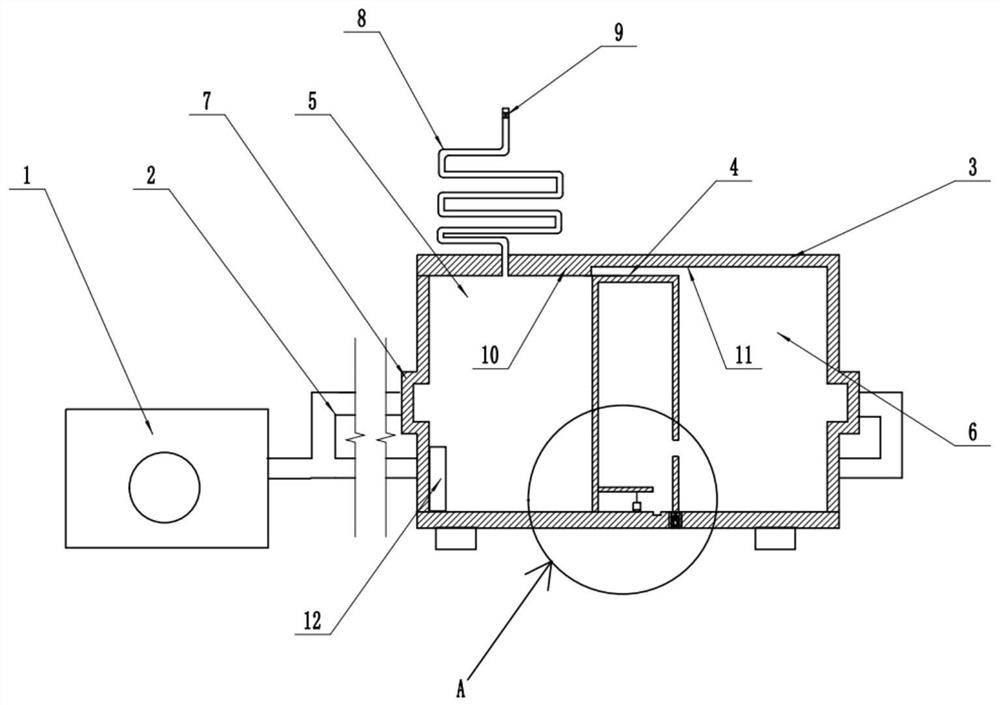

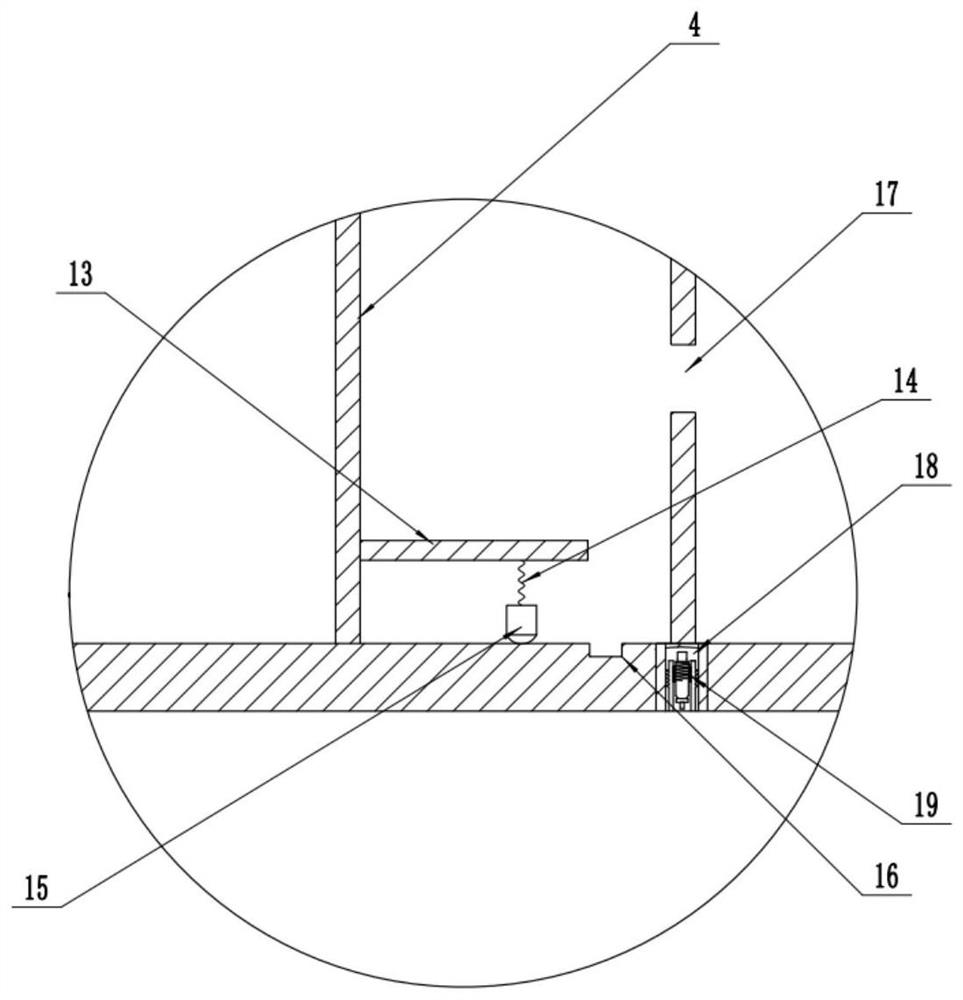

[0025] Reference numerals in the accompanying drawings include: negative pressure machine 1, three-way pipe 2, casing 3, hollow column 4, water supply chamber 5, water storage chamber 6, taking the vacation interface 7, water pipe 8, filter Net 9, high-oriented, low-step 11, heating tube 12, lateral branch plate 13, tube spring 14, lock head 15, lock hole 16, vent hole 17, gas permeable hole 18, mechanical valve 19.

[0026] Embodiments are basically figure 1 As shown: An operating room temporarily prepared a distilled water device including a negative pressure press 1 and a three-way conduit 2, further comprising a casing 3, a vertical hollow column 4 with a vertical hollow column 4, a hollow column 4 and a casing 3 Slide, the hollow column 4 divides the casing 3 into the inlet chamber 5 and the water storage chamber 6, and the inlet chamber 5 and the water storage chamber 6 are tak...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap