CSPC highlight floor and preparation method thereof

A technology of flooring and PVC resin, applied in the field of CSPC high-gloss flooring and its preparation, can solve the problems of rough raw materials, low-quantity wear-resistant surface paper, and large changes in environmental temperature and humidity, and achieve the effect of eliminating hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

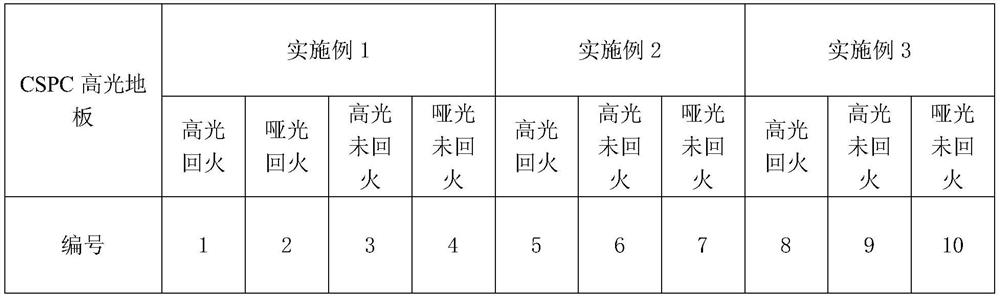

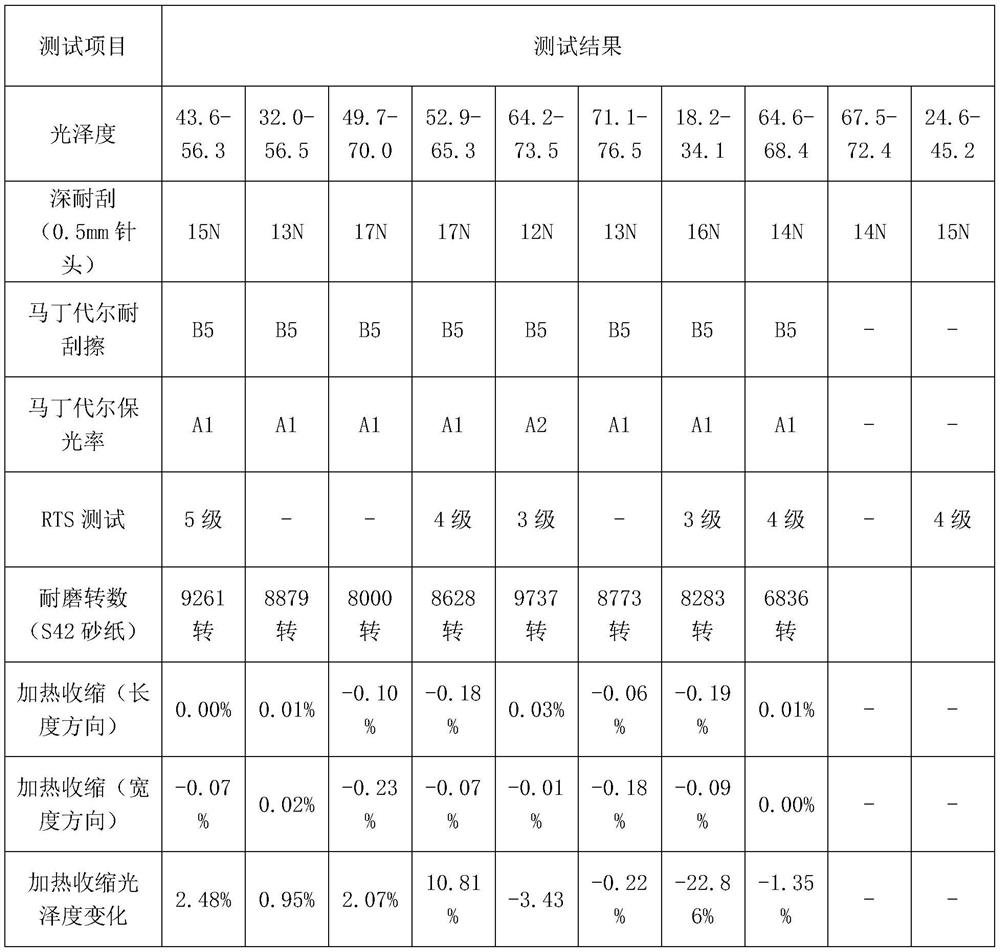

Examples

Embodiment 1

[0017] For the CSPC high-gloss floor of the present embodiment, the base material of the floor comprises the following raw material components in parts by weight: 27 parts of PVC resin, 63 parts of stone powder, 6 parts of calcium zinc stabilizer, 10 parts of plasticizer and 2 parts of soybean oil.

[0018] The preparation method of the CSPC high-gloss floor of the present embodiment may further comprise the steps:

[0019] (1) PVC resin is mixed with stone powder, then calcium-zinc stabilizer, plasticizer and soybean oil are added and mixed to obtain a mixture;

[0020] (2) Extrude the mixture to form a stone-plastic base plate under the conditions of vacuuming and a temperature of 160°C;

[0021] (3) The color film and transparent sheet are hot-pressed with the stone-plastic base plate, and the hot-pressing temperature is controlled at 120°C;

[0022] (4) Carry out roller coating to the semi-finished product after hot-press forming, and the paint of roller coating adopts UV...

Embodiment 2

[0025] For the CSPC high-gloss floor of the present embodiment, the base material of the floor comprises the following raw material components in parts by weight: 37 parts of PVC resin, 73 parts of stone powder, 8 parts of calcium zinc stabilizer, 20 parts of plasticizer and 6 parts of soybean oil.

[0026] The preparation method of the CSPC high-gloss floor of the present embodiment may further comprise the steps:

[0027] (1) PVC resin is mixed with stone powder, then calcium-zinc stabilizer, plasticizer and soybean oil are added and mixed to obtain a mixture;

[0028] (2) Extrude the mixture to form a stone-plastic base plate under the conditions of vacuuming and a temperature of 180°C;

[0029] (3) The color film and transparent sheet are hot-pressed with the stone-plastic base plate, and the hot-pressing temperature is controlled at 140°C;

[0030] (4) Carry out roller coating to the semi-finished product after hot-press forming, and the paint of roller coating adopts UV...

Embodiment 3

[0033] For the CSPC high-gloss floor of the present embodiment, the base material of the floor comprises the following raw material components in parts by weight: 32 parts of PVC resin, 68 parts of stone powder, 7 parts of calcium-zinc stabilizer, 15 parts of plasticizer and 4 parts of soybean oil. The preparation method of the CSPC high-gloss floor of the present embodiment may further comprise the steps:

[0034] (1) PVC resin is mixed with stone powder, then calcium-zinc stabilizer, plasticizer and soybean oil are added and mixed to obtain a mixture;

[0035] (2) Extrude the mixture to form a stone-plastic substrate plate under the conditions of vacuuming and a temperature of 170°C;

[0036] (3) The color film and transparent sheet are hot-pressed with the stone-plastic base plate, and the hot-pressing temperature is controlled at 130°C;

[0037] (4) Carry out roller coating to the semi-finished product after hot-press forming, and the paint of roller coating adopts UV pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com