PC/PBT composite material and preparation method and application thereof

A technology of composite materials and initiators, applied in the field of engineering plastics, can solve problems such as the difficulty of making materials transparent, and achieve the effects of good toughness, high light transmittance, and improved fluidity

Pending Publication Date: 2022-04-12

KINGFA SCI & TECH CO LTD

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the transesterification reaction is a relatively weak reaction, the PBT content in the prepared resin com

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

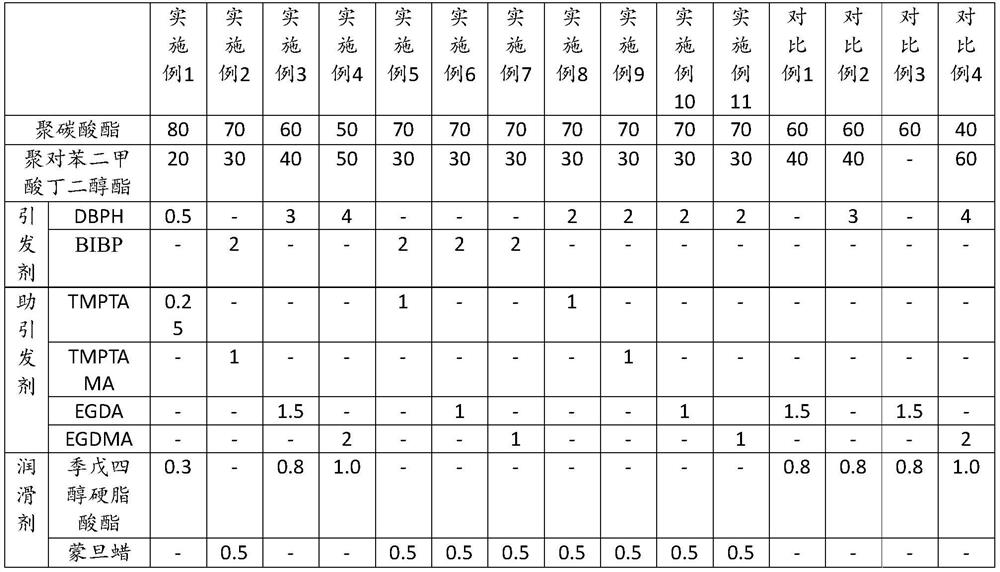

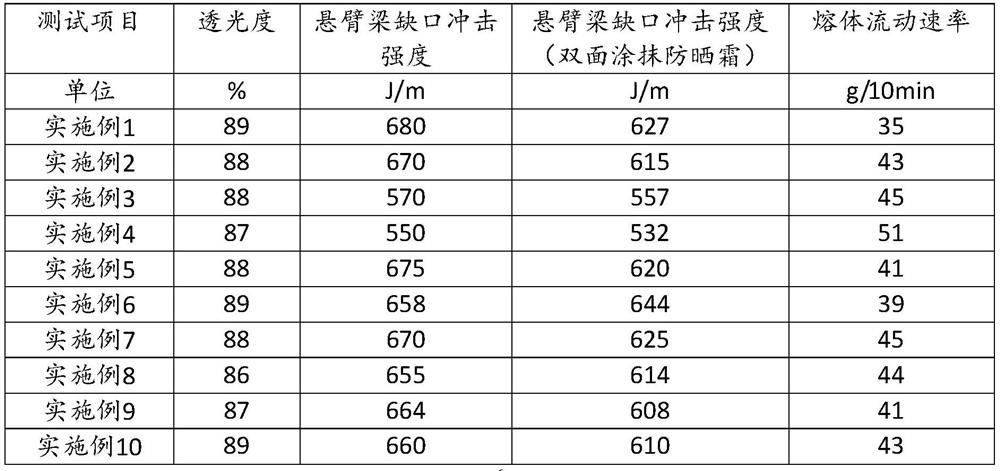

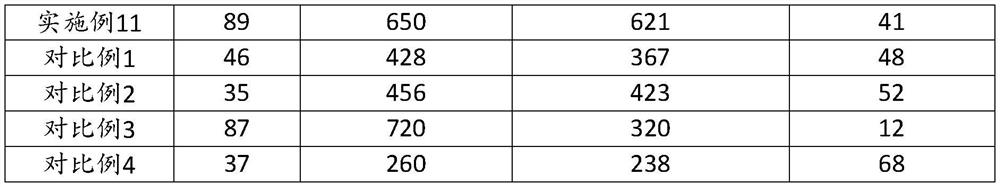

The invention provides a PC/PBT composite material as well as a preparation method and application thereof, and relates to the technical field of engineering plastics. The PC/PBT composite material provided by the invention is prepared from the following components in parts by weight: 50 to 80 parts of polycarbonate, 20 to 50 parts of polybutylene terephthalate, 0.5 to 4 parts of initiator, 0.25 to 2 parts of co-initiator and 0.3 to 1.0 part of lubricant, and the initiator is peroxide. The peroxide is used as an initiator to catalyze a grafting reaction between polycarbonate and polybutylene terephthalate, and a peroxide initiation system is subjected to a free radical reaction, so that rapid and efficient grafting is performed between PC and PBT molecular chains, and when the addition amount of PBT in the raw materials is relatively high, the prepared composite material is high in light transmittance and good in toughness. And in addition, the fluidity of the composite material is also obviously improved.

Description

technical field [0001] The invention relates to the technical field of engineering plastics, in particular to a PC / PBT composite material and its preparation method and application. Background technique [0002] Polycarbonate (PC) is an engineering resin with excellent comprehensive performance. The commonly used bisphenol A polycarbonate is widely used in the automotive industry for its outstanding impact strength, dimensional stability, transparency, and weather resistance. , electronics, office equipment and other fields have been widely used. However, the PC molecular chain has strong rigidity, large internal stress after molding, and poor chemical solvent resistance. Therefore, under the erosion of chemical solvents, it will cause the release of internal stress and cause cracking. The molecular chain of polybutylene terephthalate (PBT) is relatively flexible, and part of the internal stress can be offset by the movement of the molecular chain. By grafting PBT molecula...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08G81/00C08L87/00

Inventor 李红刚叶南飚陈平绪艾军伟吴俊

Owner KINGFA SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com