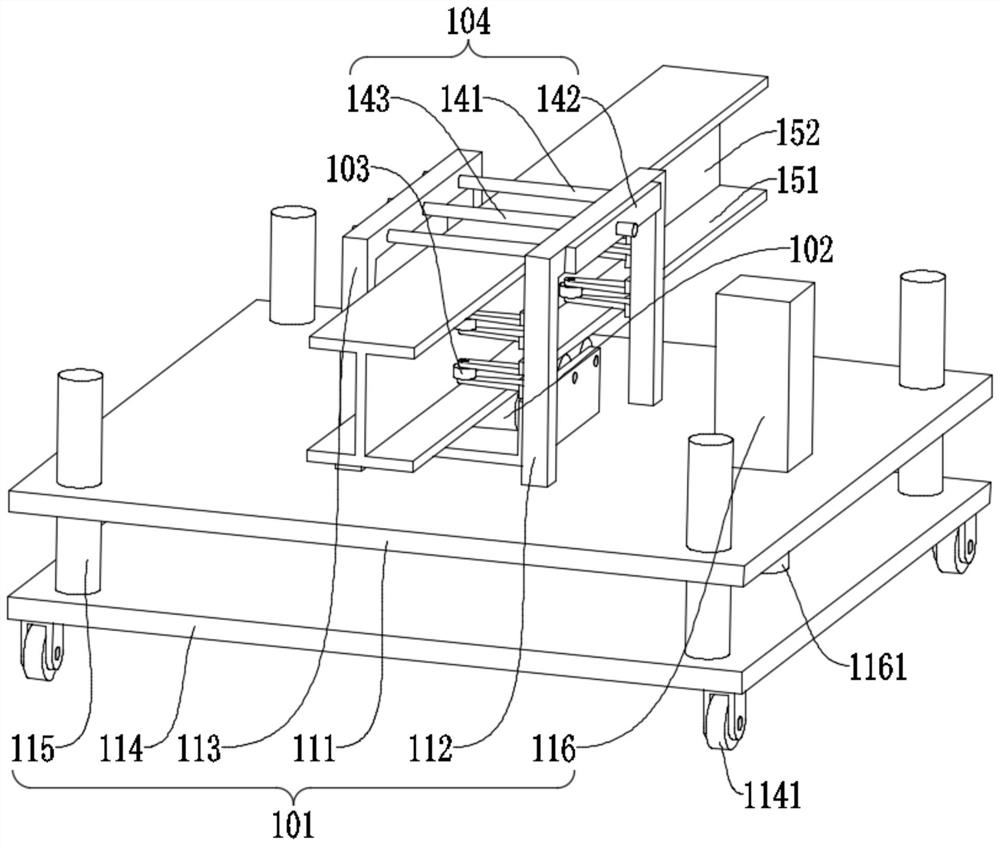

Automatic penetrating and pulling system and method for reinforcing I-shaped steel of jacking line of frame structure bridge

A technology for I-beam and frame-structured bridges is applied in the field of I-beam automatic threading and drawing systems for strengthening the jacking line of frame-structured bridges, and can solve the problems of high labor intensity and high risk factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

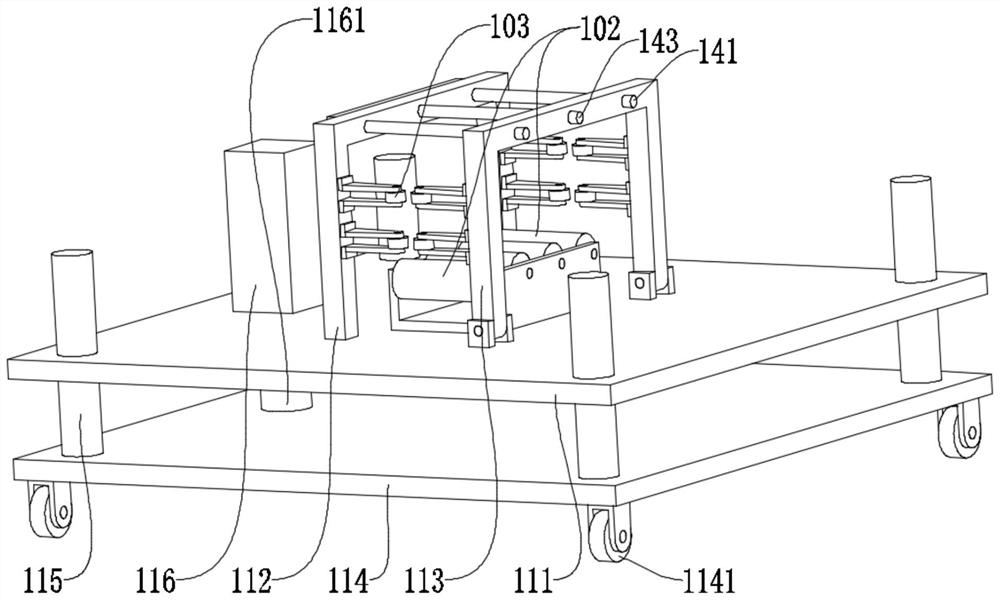

Examples

specific Embodiment approach

[0078] see figure 2 , a kind of specific implementation mode that the present invention provides again on the basis of above-mentioned implementation mode is as follows:

[0079] The roller bracket 312 is also provided with a screw hole and a stud 314 matched with the screw hole. The screw hole is located above or below the fourth roller 311 . The stud 314 passes through the screw hole and abuts against the mounting bracket 313 .

[0080] When the fourth roller 311 cooperates with the side of the I-beam web, the screw hole is set under the fourth roller 311, and the length of the stud 314 is shorter than the length of the fourth roller 311, so as to avoid scratching the I-beam Upper wing plate and web; When the fourth roller 311 is matched with the side of the I-beam web, the screw hole is preferably located under the fourth roller 311, and the length of the stud 314 is longer than the fourth roller 311, which can The upper part of the I-beam is limited.

[0081] On the one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com