Temporary back-jacking support construction method

A construction method and temporary technology, applied in the preparation of pillars and building components on site, construction, etc., can solve the problems of inconvenient demolition, large structural span, and heavy workload of supporting frames, and achieve convenient installation and demolition and improve construction. efficiency, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

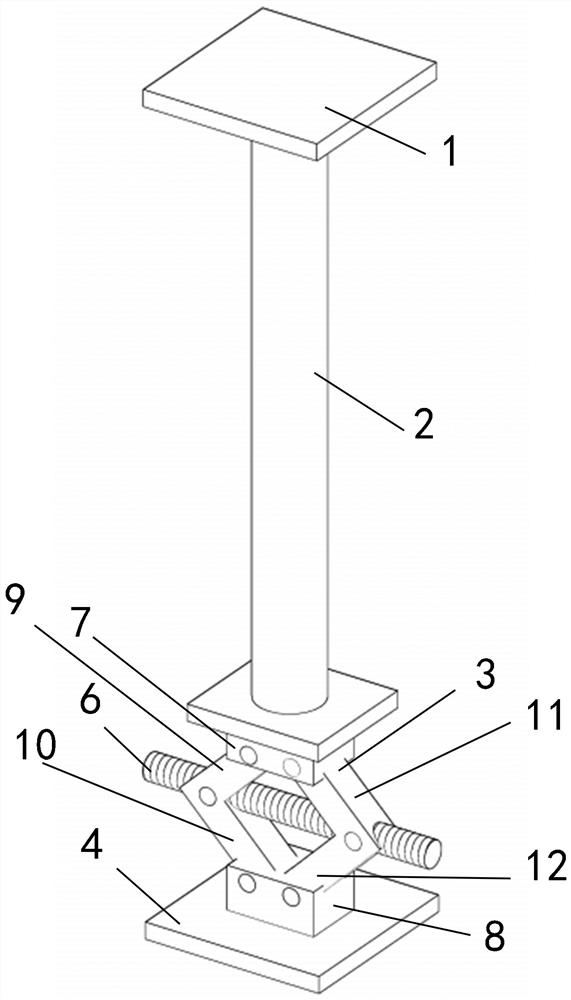

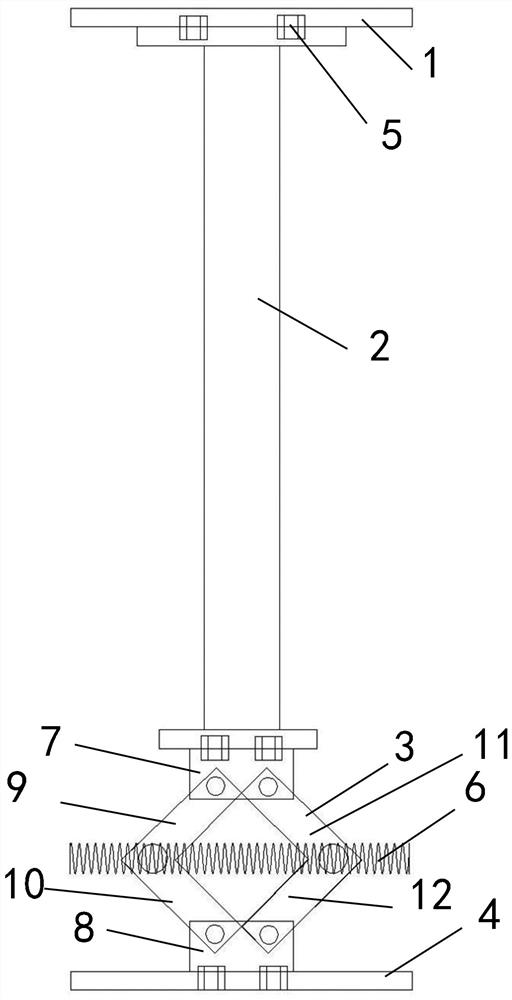

[0012] See attached picture. This embodiment consists of a top plate 1, a support column 2, a lifting device 3, and a base 4 from top to bottom. The dimensions of the steel top plate and the steel base are both 300 mm long, 300 mm wide, and 20 mm high. The solid vertical steel support column has a height of 2 m and a radius of 40 mm. ;The top plate 1 is used to support the object that needs to be supported by the top. The steel top plate 1 and the steel support column 2, the steel support column 2 and the lifting device 3, and the lifting device 3 and the base 4 are all connected by bolts 5, and the bolt 5 is used to connect , easy to disassemble during use; the lifting device 3 is used to adjust the height, and the lifting device includes a first connecting block 7, a second connecting block 8, a first rotating arm 9, a second rotating arm 10, and a third rotating arm 11. The fourth rotating arm 12, the first connecting block 7 and the second connecting block 8 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com