Pressurizing system of double-screw air blower

A pressurization system and blower technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as difficult to achieve air compression effect, achieve the effect of improving import efficiency, increasing air pressure, and accelerating export rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the technical solution of the present invention more clearly and completely, the present invention will be further described below in conjunction with the accompanying drawings.

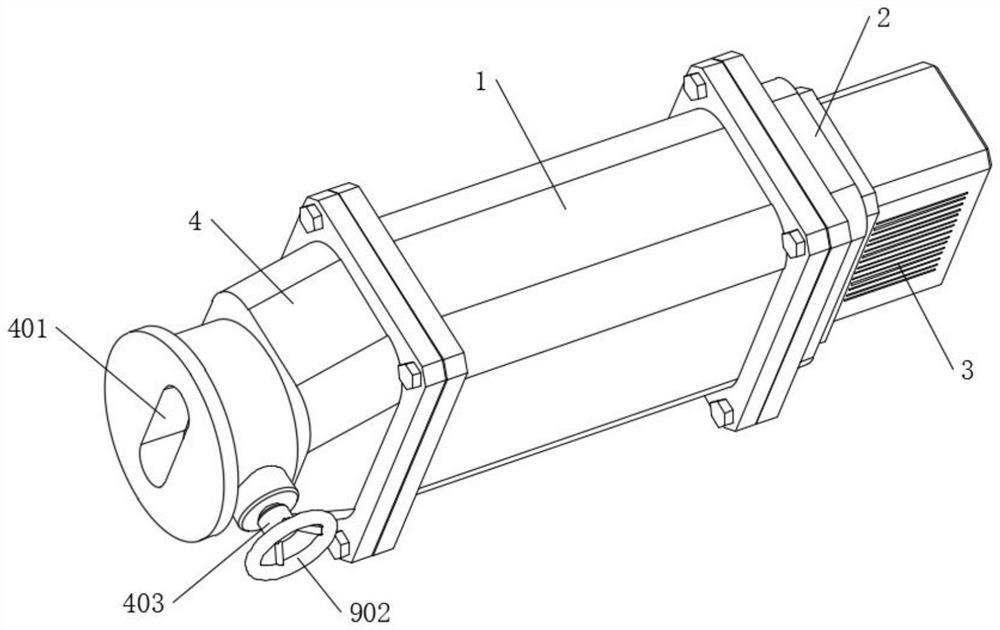

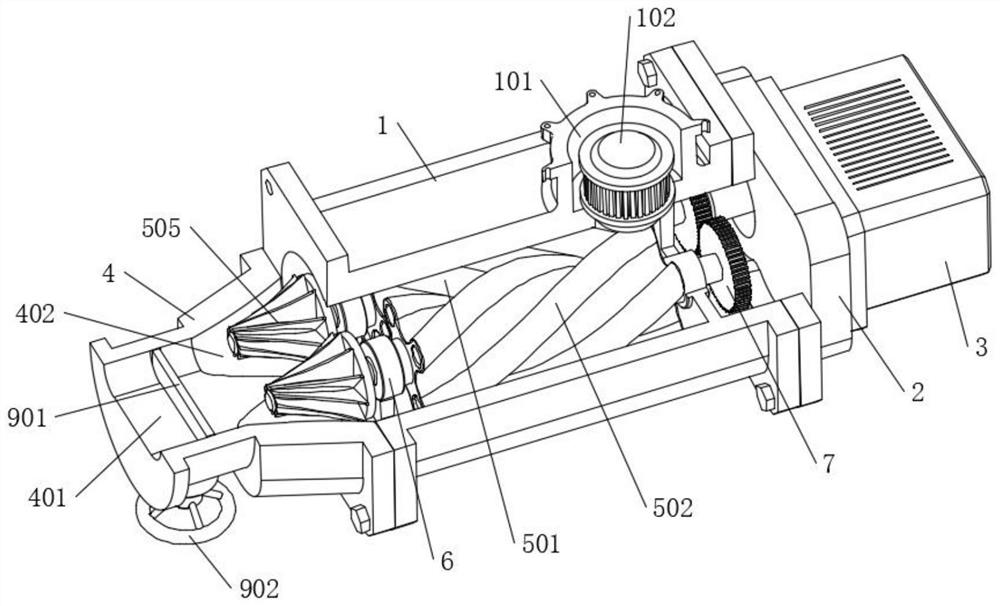

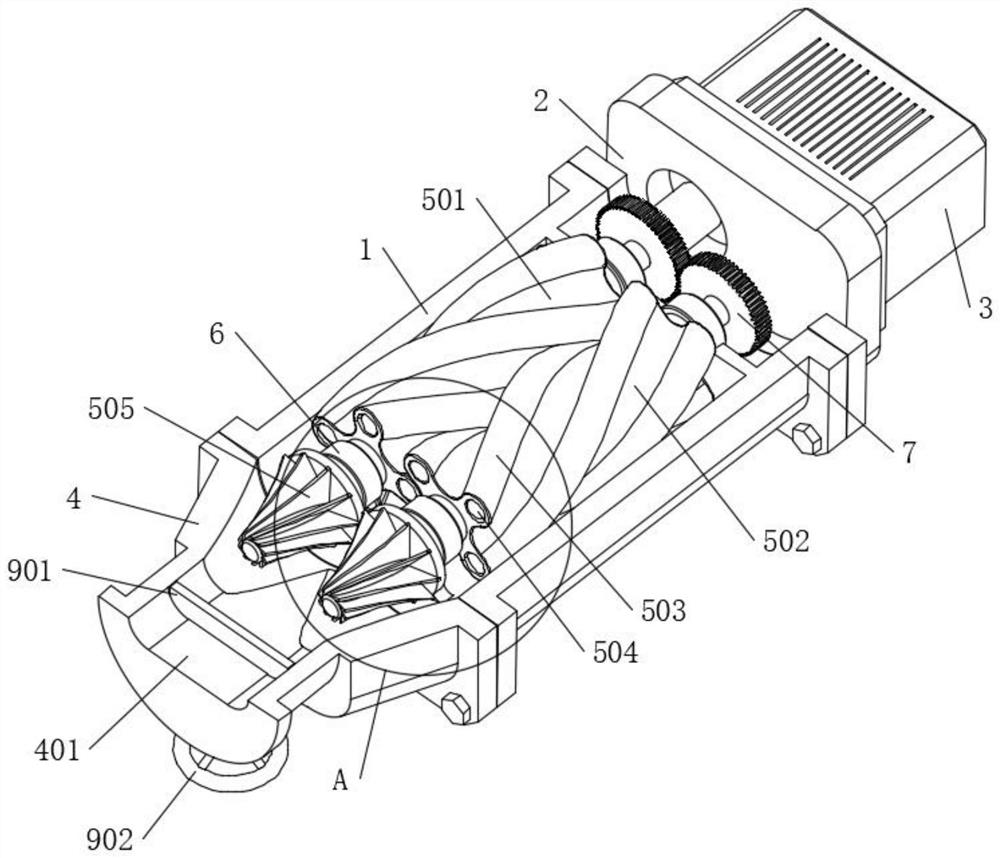

[0025] Please refer to Figure 1-Figure 6 , the present invention proposes a pressurization system for a twin-screw blower, which includes a blower body 1, and a screw rotor group 5 is arranged inside the blower body 1, and the screw rotor group 5 is composed of a male screw rotor 501 and a female screw rotor 502 arranged in parallel The two axial ends of the male screw rotor 501 and the female screw rotor 502 are supported in the blower body 1 through the bearing housing 6, one end of the blower body 1 is fixed with a cover 2 by bolts, and the outer wall of the cover 2 is fixed with bolts. The motor 3, and the output shaft of the motor 3 and one shaft end of the male screw rotor 501 are connected through a coupling 8, and the other end of the blower body 1 is fixed with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com